Machine d'emballage sous blister entièrement servo

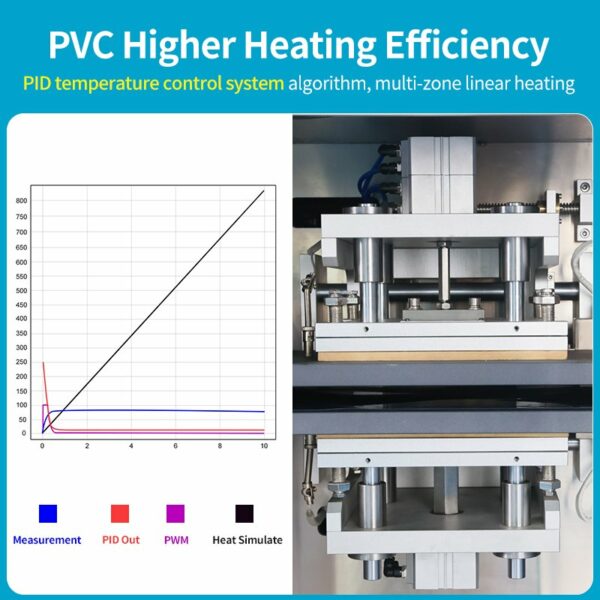

Machine d'emballage sous blister entièrement servocommandée est une machine d'emballage sous blister aluminium-plastique à plaque à rouleaux intelligente à grande vitesse développée indépendamment pour les grands fabricants de produits pharmaceutiques et de soins de santé, mettant en évidence les avantages technologiques du contrôle intelligent.

L'ensemble de la machine se compose de six ensembles de contrôleurs de mouvement et de systèmes de servocommande, et a pris les devants pour atteindre l'objectif de changement de moule rapide et de démarrage et d'arrêt à un seul bouton, réduisant considérablement les coûts de main-d'œuvre et réalisant un saut qualitatif dans l'intelligence et la commodité de fonctionnement.

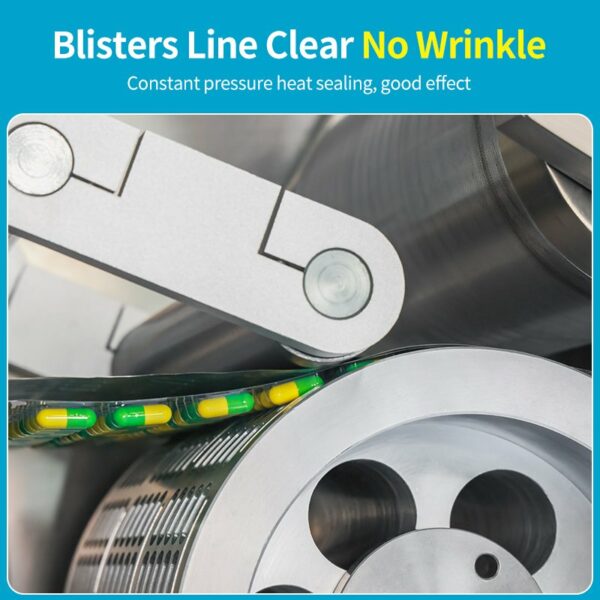

L'ensemble de la machine est résolument innovant grâce à sa conception modulaire cloisonnée. La haute précision de l'équipement simplifie l'alignement complexe des postes et facilite la compression des blisters. Le fonctionnement est plus stable et le réglage est plus pratique et rapide.

Spécification:

Jusqu'à 27 000 ampoules/min

Applicable aux comprimés, capsules et médicaments, etc.

Livraison rapide en 15 jours