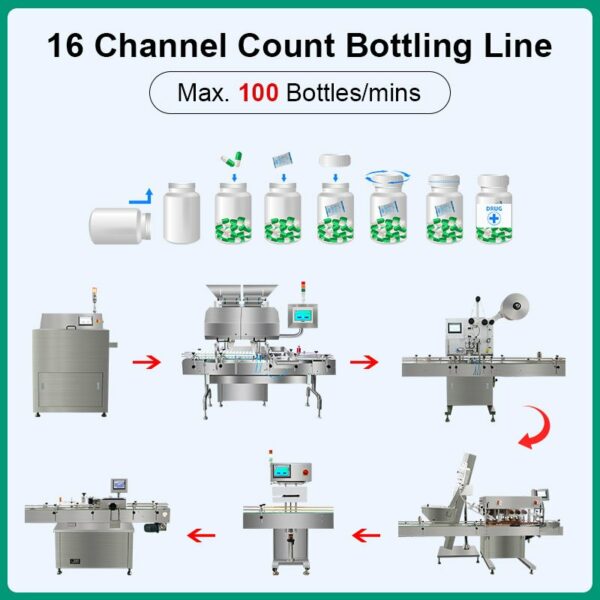

Ligne d'embouteillage de capsules

Ligne d'embouteillage de capsules composants :

Démêleur de bouteilles : Les bouteilles sont automatiquement introduites dans la ligne à l'aide d'un convoyeur ou d'un plateau tournant.

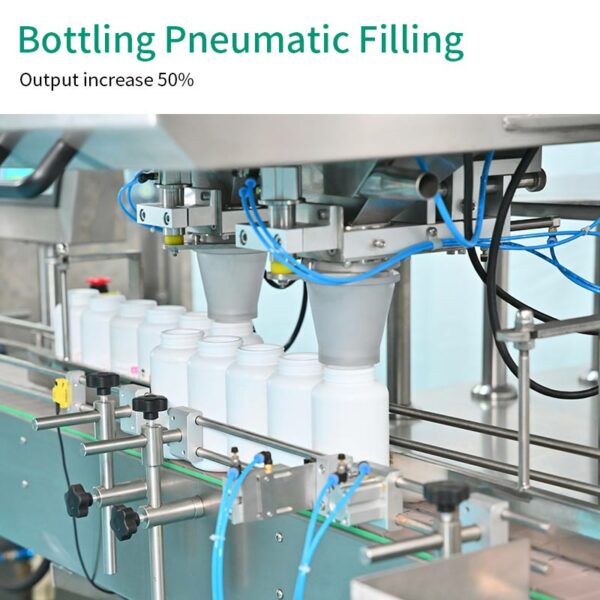

Machine de comptage : les capsules sont remplies dans des bouteilles après le comptage.

Inserteur de déshydratant : insère des sachets déshydratants dans les bouteilles pour maintenir la stabilité de la capsule et éviter les dommages causés par l'humidité.

Machine de capsulage : Bouche automatiquement les bouteilles remplies pour les sceller.

Machine de scellage par induction : scelle la bouteille avec une couche de papier d'aluminium pour garantir l'inviolabilité et préserver la fraîcheur du produit.

Étiqueteuse : applique des étiquettes sur les bouteilles avec des informations sur le produit, des numéros de lot, des dates d'expiration et des codes-barres.

Spécification:

Jusqu'à 100 bouteilles/min

taux de précision > 99,98%

Convient aux capsules/comprimés/gélatines de 3 à 40 mm…