Lorsque vous ouvrez un paquet de M&M's, il est facile d'oublier la technologie sophistiquée qui garantit que chaque morceau coloré est parfaitement compté, pesé et scellé. Derrière cette douce simplicité se cache un processus d'emballage avancé, conçu pour répondre à la demande mondiale avec efficacité et précision. Aujourd'hui, nous allons examiner de plus près les deux principaux types d'emballage des M&M's - l'emballage en sac et l'emballage en bouteille - et la technologie qui les rend possibles.

1. Emballage en sac - économique

L'emballage en sachet est le moyen le plus courant et le plus rentable d'emballer les M&M's. Cette méthode s'adresse principalement aux familles ou aux ménages qui préfèrent les produits à bon prix. Cette méthode s'adresse principalement aux familles ou aux ménages qui préfèrent les produits d'un bon rapport qualité-prix. L'emballage en sachet est non seulement abordable, mais aussi pratique pour le partage et le stockage.

Pour l'emballage de gros volumes, la vitesse est plus importante que la précision pièce par pièce. Dans ce cas, les fabricants utilisent une peseuse associative avec une machine d'emballage de sachets préfabriqués.

La peseuse associative fonctionne en pesant simultanément plusieurs petits lots de M&M's. L'ordinateur du système calcule rapidement la combinaison des godets de pesée dont le poids total est le plus proche de la valeur cible. L'ordinateur du système calcule rapidement la combinaison de godets de pesée dont le poids total est le plus proche de la valeur cible.

Le doypack machine d'emballage de sachets Le système effectue ensuite automatiquement une série d'étapes : sélection des sachets, codage de la date, remplissage et scellage. Le résultat est un sachet de M&M's soigneusement emballé et parfaitement portionné, prêt à être mis en rayon. Cette méthode est exceptionnellement rapide et efficace, parfaite pour les lignes de production à haut rendement.

Le principal avantage de cette méthode réside dans sa rapidité et son efficacité. Elle est idéale pour les situations de forte demande où le volume de production importe plus que la précision.

2. Conditionnement des bouteilles - Portable et Premium

Alors que l'emballage en sac est le plus abordable, l'emballage en bouteille est conçu pour une expérience plus haut de gamme et plus portable. Cette méthode d'emballage séduit les consommateurs à forte valeur ajoutée qui apprécient la commodité des bouteilles refermables qui peuvent facilement se glisser dans les sacs, les porte-gobelets ou les bureaux.

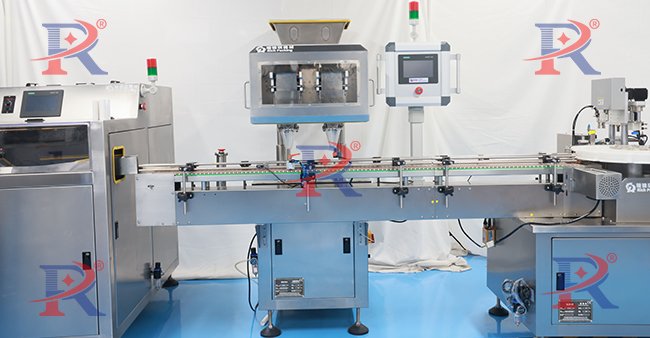

L'emballage des bouteilles de M&M's implique généralement une ligne de production complète de comptage et d'embouteillage, composée de plusieurs machines automatisées fonctionnant ensemble de manière transparente.

2.1. Tri des bouteilles

Le processus commence par un démêleur de bouteilles, une machine qui place les bouteilles vides dans le bon sens et les dépose sur le tapis roulant. Cela permet de s'assurer que chaque bouteille passe sans encombre à l'étape suivante de la production.

2.2. Comptage et remplissage

Les bouteilles se dirigent vers une machine à compter les comprimés, qui est chargée de compter les M&M's avec précision et de les déposer dans les bouteilles. Le nombre de bonbons par bouteille peut être personnalisé en fonction des spécifications du produit ou des besoins marketing.

La machine à compter les bouteilles utilise des capteurs optiques et une alimentation par vibration pour s'assurer que chaque pièce est séparée et comptée avec précision - pas de bouteilles cassées ou trop pleines.

2.3. Bouchage et étiquetage

Après le remplissage, les bouteilles sont acheminées le long du convoyeur jusqu'à la machine à boucher, où les bouchons sont automatiquement serrés pour garantir la sécurité et la fraîcheur du produit. Les bouteilles sont ensuite acheminées vers l'étiqueteuse ou la machine à manchons rétractables, qui applique les étiquettes ou les manchons décoratifs qui donnent aux M&M's leur aspect vibrant et reconnaissable.

L'ensemble du processus - du tri à l'étiquetage - est continu, automatisé et extrêmement fiable. Le résultat est une bouteille professionnelle et visuellement attrayante qui reflète l'engagement de la marque en matière de qualité et d'innovation.

3. Ruidapacking peut fournir des solutions complètes

Derrière ces systèmes d'emballage efficaces se trouvent des fabricants spécialisés dans les machines pharmaceutiques et d'emballage - Guangzhou Ruida Packing Machinery Co, Ltd.

Ruidapacking se concentre sur la recherche, le développement, la fabrication, la vente et le service après-vente de machines pharmaceutiques et d'emballage, fournissant des solutions clés en main complètes aux clients du monde entier. Ses principaux produits, les machines de remplissage de gélules et les presses à comprimés, ont reçu une large reconnaissance de la part des clients internationaux, y compris des leaders mondiaux tels que USPharma, Robinson, ATLANTIC GRUPA, et SINOPHARM, etc.

Avec un engagement fort pour la précision, la fiabilité et la personnalisation, Ruidapacking aide ses clients à construire des lignes de production qui répondent aux normes cGMP et FDA. Que vous ayez besoin d'une ligne de comptage et d'embouteillage pour les M&M's, d'une ligne d'emballage de sachets préfabriqués à pesage multiple ou d'une machine d'emballage pour l'industrie pharmaceutique, l'équipe d'ingénieurs de Ruidapacking peut concevoir une solution qui répond parfaitement à vos besoins.

Conclusion

En conclusion, le choix entre l'emballage en sac et l'emballage en bouteille pour les M&M's dépend souvent du positionnement sur le marché et des consommateurs cibles.

L'emballage en sac est l'option de choix pour des raisons de coût, d'efficacité et de distribution de masse.

L'emballage des bouteilles, quant à lui, s'adresse aux consommateurs qui recherchent la commodité, la portabilité et une présentation de qualité.

Des simples sachets en plastique aux bouteilles élégantes, chaque emballage est le résultat d'une excellence technique et d'une innovation technologique, preuve que même les plus petits bonbons méritent les solutions d'emballage les plus avancées.