Machine de remplissage automatique de capsules NJP-400C

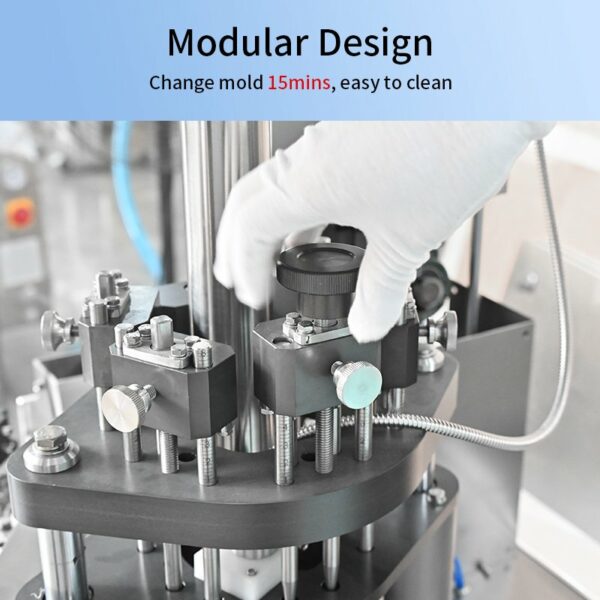

NJP-400C automatic capsule filling machine can fill powder, granules, and pellet into hard capsules. The filling mechanism adopts a modular design, which is convenient for cleaning and maintenance; the scale is adjusted, and the filling accuracy is less than 0.1mm. The turntable design has obtained a utility model patent. Capsule filler uses SIL imported rubber and silicone sealing rings to effectively prevent pharmaceutical powder from entering the interior of the turntable. It has good sealing performance and no dust spillage and pollution. The turntable’s transverse dual axes use polytetrafluoroethylene oil-free bearings, which require no oil or maintenance for life.

Equipped with vacuum capsule feeding machine, powder feeding machine and polishing machine. Full automatic capsule filling machine meets the cGMP requirements, which makes it an ideal equipment for filling medicines and nutrients.

Spécification:

Jusqu'à 24 000 pièces/h

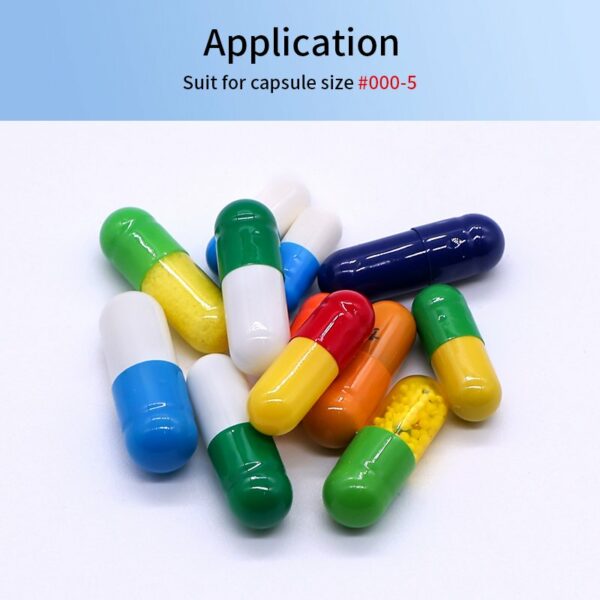

Applicable pour #000 ~ 5 capsules

Livraison rapide en 15 jours

Convient pour la poudre, les granulés, les pastilles et les comprimés