We understand the thought: With so many gelatin capsule options at drugstores or grocery shops, why do you need to go through the effort to make your own capsules? We were once skeptical, too. Now our investigation has uncovered some compelling reasons for manually making capsules.

Reason 1: Know Exactly What You Ingest

In a world where supply chains are long and ingredient lists are often confusing, have you ever paused to wonder what exactly is inside gel capsules and capsule supplements that you take every day? The movement to make your own capsules is rooted in principle: ultimate transparency and personalized wellness. It relates with managing your physical health, one supplement capsule at each time.

●Uncompromising Purity and Personalized Formulation

When you make your own supplements, you are the master of your formula. Do you want to be sure that your supplement capsules contain only the pure, suitable active ingredients for your unique body, without any hidden fillers, flow agents, or artificial additives.

Based on this consideration, why do you still rely on nutritional supplement capsule suppliers whose proprietary ingredient blends may not align with your specific health goals or dietary principles?

To make your own supplements, you can make your own vitamin pack that addresses your individual needs. Whether it is making a herbal blend for energy, a customized vitamin mix, or excluding an allergen commonly used as a filler in commercial capsules. The hands-on approach to create supplements ensures that every milligram of ingredient serves a purpose you trust.

●Ethical Assurance for Every Lifestyle

For vegetarians, vegans, and those with specific ethical or religious dietary standards, the issue of capsule composition is critical. The hard capsules you routinely consume from store-bought bottles are typically made from gelatin, a protein derived from animal bones and connective tissues. Suppose that you are a vegetarian, when you create your own capsules, you have the freedom to choose plant-based vegetarian capsule shells like pullulan capsules or HPMC capsules, ensuring every aspect of your supplement—from inner contents to outer capsule shells—aligns with your values and lifestyle.

If you need to understand more about vegetable capsules VS gelatin capsules, please read this article.

By choosing gelatin or vegetarian capsule shells, and active ingredients to make your own supplements, you are not just making your own supplements; you are making a conscious commitment to material purity, lifestyle personalization, and peace of mind.

Reason 2: Simpler than You Imagine to Create Your Own Supplement

To make your own capsules may initially seem like a complex task, but the filling capsules process is far more accessible than it appears. With clear guidance, you can make your own supplement capsules while sitting on the sofa at your home.

You don’t need a academic background in pharmacy or a sophisticated, automatic capsule making machine to begin. The entire capsule making operation can be successfully managed by using simple, manual tools designed for home use, such as a manual capsule filler and a tamper. These user-friendly devices efficiently guide you through each critical stage, from separating capsule shells and precisely filling the capsule body with your chosen powder to securely reassembling the two capsule parts.

What seems like a technical challenge is, in reality, an easily acquired skill. This empowering activity puts you in complete control, turning you from capsule supplement customer into a creative maker of your own health supplements.

Reason 3: Low-Cost Initial Investment

A primary advantage of making your own supplements capsules is the low barrier to entry. Unlike industrial capsule manufacturing which requires significant capital for an automatic encapsulation machine, tiny-scale hard capsule production does not demand expensive capsule making machines.

The essential toolkit is straightforward and affordable. All that is required are empty hard gelatin or vegetarian capsules, a manual capsule pill maker—a simple, non-electric device designed for ease of use—and your chosen powdered or granular ingredients, such as herbs, vitamins, or raw supplements. By investing in this minimal capsule making equipment, you gain direct control over your capsule production, eliminating the substantial markups typically associated with pre-packaged commercial brands.

What’s more, if you don’t want any investment in a simple gelatin capsule machine filler, you can choose to use a spoon, a funnel, and a weighing scale to easily let your vegetarian or gelatin capsules encapsulate your raw powdered capsule ingredient.

How to Make Your Own Supplements Capsules?

To successfully create your own supplement requires gathering a few essential materials and tools before you load gel capsules with powder.

●Capsule Shells

Le capsule filling process begins with empty capsule shells in your preferred capsule size. Commonly seen options are capsule sizes 00 and 0 for their generous filling capacity. Hard gelatin capsules of these sizes can hold approximately 750mg and 650mg of powdered ingredients respectively.

These common capsule sizes can be purchased on websites and at a pharmacy. It’s worth noting that capsule shells are not all the same; vegetarian capsule shells are derived from plant-based sources, while others are gelatin derived from animal skin and collagen.

●Contents for Your Capsule Remplissage

Begin to make your own capsules at home by choosing high-quality health supplement ingredients that align with your nutritional formula. Suitable options include vitamins, minerals, and various forms like powders, oils, or granules. It is essential to verify all ingredients are pure and uncontaminated.

These active ingredients for filling capsules are readily available for purchase online or at local drugstores. Once acquired, ensure capsule ingredient is mixed together entirely until the mixture is evenly consistent. For a finer texture, you may need to grind materials into delicate powder by using a pestle.

If you would like to use fresh herb instead of store-bought ingredients, start by dehydrating herbs completely. After the drying process, use a grinder or food processor to create a uniform herbal powder suitable for your hard gelatin capsule filling.

●Precision Scale

To achieve milligram-level accuracy in capsule fill weight, a high-precision scale is essential to ensure consistent dosing across different capsule sizes, each of which requires a specific powder weight.

●Additional Tools

The tools include a funnel and a spoon. They are supposed to facilitate clean and easy capsule filling, minimizing material spillage and waste. For improvisation, a simple funnel can be prepared by rolling a piece of paper.

How to Make Your Own Capsules at Home?

How to make capsules by your hands at home? It is highly scalable and can be carried out in small, manageable batches. The flexibility makes manual capsule making a practical and economical method for individuals seeking to create their supplement capsules. This hands-on approach not only ensures purity and customization but also translates to significant long-term savings.

1. Scooping Way

As a quick and tool-free approach, the scooping method is ideal to manually make your own vitamins. This technique is designed for simplicity, allowing anyone to load capsules with powder avoiding complex procedures.

Step 1: Begin by placing your chosen powder or other ingredient for manual capsule filling into a dry, clean dish.

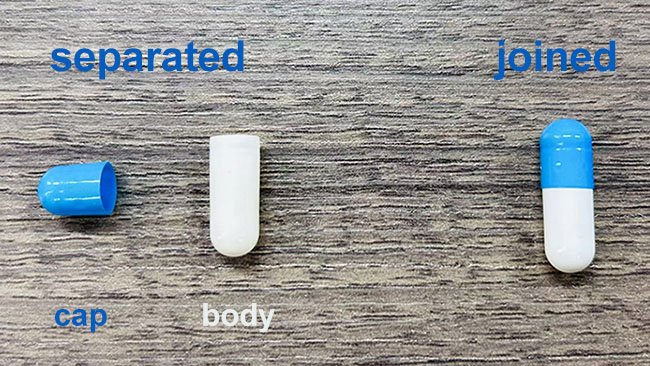

Step 2: Carefully separate an empty hard gel capsule into two halves—a capsule cap and a capsule body—and place them on a clean, dry surface. Capsule halves should come apart effortlessly, similar to separating two interlocking pieces.

Step 3: Gently press both the capsule cap and body into powdered ingredient, submerging them and prepare them for capsule filling.

Step 4: By using a scooping technique, fill the capsule body completely with powdered capsule ingredient. The cap section, however, should only have a small amount of powder to ensure a clean and seamless capsule locking later.

Step 5: To seal your gelatin or vegetarian capsule, bring the filled capsule body and its corresponding cap together and press down with gentle finger pressure until two halves are securely locked.

2. Le Funnel et Spoon Technique

This straightforward approach requires just a few common household items: a spoon, a makeshift funnel, and optionally, a scale for precision.

If a funnel is out of reach, you could create one by converting paper into a cone-shaped funnel. This method is not only simple but also allows for carefully measured dosages in each dietary supplement capsule.

Step 1: Begin by placing your chosen powder or filler substance into a clean, dry bowl.

Step 2: Take an empty plant based or gelatin capsule and carefully separate it into its two halves: the larger capsule body and the smaller capsule cap.

Step 3: Roll a piece of paper into a cone to form a simple funnel.

Step 4: Position the narrow end of your paper funnel into the opening of the capsule body.

Step 5: Use a spoon and transfer a small amount of powder into the funnel, allowing the powdered ingredient to fill the capsule body. Repeat this process to fill the capsule cap as well. For precise measurement, you can use a scale to weigh the powder before loading it into capsules.

Step 6: To seal capsules, match each filled body with its corresponding cap and press them together gently until they click into place.

Need to Fill Capsules with an Automatic Capsule Making Machine?

If you are a nutraceutical or pharmaceutical capsule manufacturer seeking to produce commercial capsules in large batches, you will need to raise investment in a semi automatic or fully automatic capsule making machine.

Ruida Packing supplies automated capsule making machines capable of filling capsules from 7,000 to 460,000 pieces per hour. However, many capsule manufacturing starters do not require a large production volume. For entrepreneurs launching a pharmaceutical venture or managing a small-to-medium capsule filling operation, Ruida Packing offers a wide range of gel capsule making machines, including the semi automatic capsule filling machine CGNT 209 and the fully automatic gel cap filling machine NJP 400C, with maximum output of the latter one reaching 24,000 capsules per hour.

Operation is streamlined for productivity. Once raw ingredients are loaded into an automatic capsule making machine, this advanced capsule filler can generate a high volume of capsules quickly, controlled effortlessly through a simple touchscreen interface.

Final Lines

Capsules serve as a popular delivery method for a broad spectrum of dietary, health, and sports supplements. This format is versatile to accommodate various formulas, including pre-workout energizers, fat-burning compounds, mass gainers, and recovery aids.

To create your supplement capsules offers distinct advantages. It grants you full control over ingredients, allowing you to exclude compositions that do not align with your physical needs or fitness objectives. Furthermore, this DIY approach to make your own capsules is a cost-effective tactic, reducing the long-term expense of reaching your health and wellness goals.