دستگاه پرس قرص در مقیاس کوچک

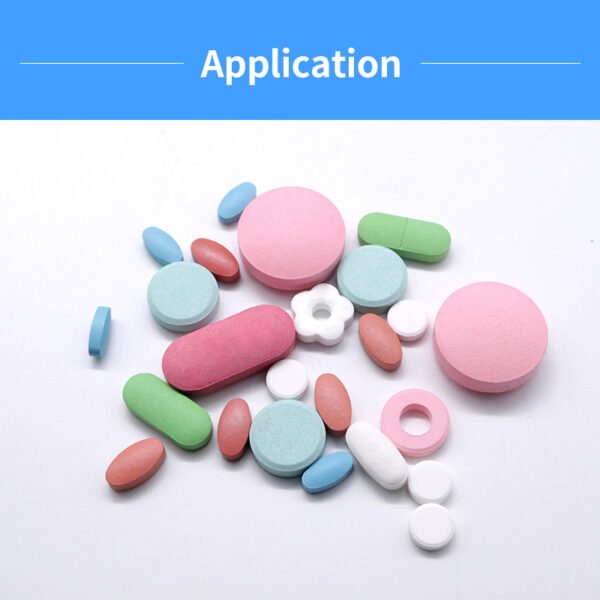

دستگاه پرس قرص در مقیاس کوچک، یک وسیله مکانیکی است که در صنایع داروسازی، مواد مغذی و شیمیایی برای فشرده سازی پودر به قرص هایی با اندازه، شکل و وزن یکنواخت استفاده می شود. در اینجا توضیح بیشتری داده شده است:

۱. برجک: قسمت چرخان دستگاه که چندین قالب و پانچ را در خود جای میدهد. با چرخش برجک، پانچها در چرخه فشردهسازی حرکت میکنند.

۲. قالبها: قطعات استوانهای که اندازه و شکل قرصها را تعیین میکنند.

۳. پانچها: اینها دو نوع هستند - پانچهای بالایی و پایینی. آنها پودر را درون قالب فشرده میکنند تا به شکل قرص درآیند. پانچ بالایی از بالا فشرده میشود و پانچ پایینی از پایین پشتیبانی را فراهم میکند.

۴. مسیر بادامکها: حرکت پانچها را هدایت میکنند. آنها تضمین میکنند که پانچها در موقعیت صحیح برای پر کردن، فشردهسازی و بیرون انداختن قرصها قرار دارند.

مشخصات:

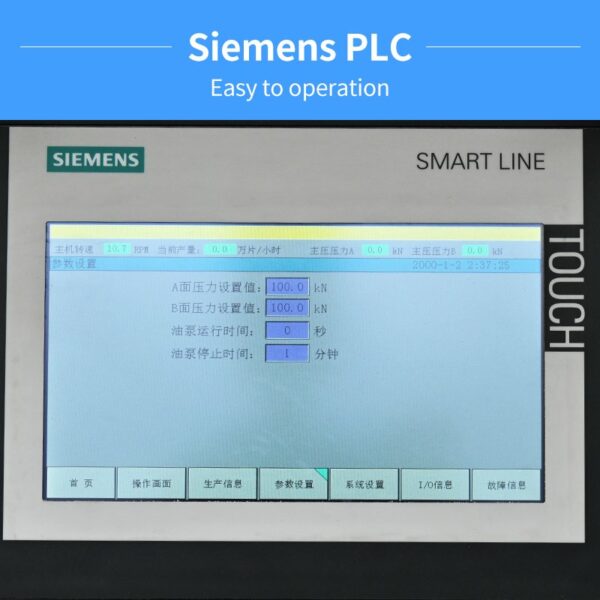

تا 37800 عدد در ساعت

حداکثر قطر قرص ۲۵ میلیمتر

حداکثر فشار ۱۰۰ کیلونیوتن

تحویل سریع ۱۵ روزه