In the competitive tablet manufacturing landscape, tableting defects and non-essential costs often stem from an unoptimized tablet compression process. Common tablet defects like cracking and chipping frequently originate not from errors of a pill press μηχανή πρέσας δισκίων, but from tablet formula deficiencies. Furthermore, tablet pressing issues such as insufficient lubrication on tooling, and inconsistent pressure application lead to unplanned tablet compress machine downtime.

Each of interruptions above represents an avoidable expense. Therefore, a proactive strategy focusing on optimizing your tablet compression is paramount for enhancing quality of pharmaceutical tablets. Following paragraphs indicate tableting defects including causes and their solutions.

1. Black Spots on Defective Tablets

Black spots or specks on compressed tablets can be concerning. Spots may appear as tiny, random dots or slightly larger smudges, often contrasting with the color of pharmaceutical tablets. Producing defective tablets with black spots is a costly nightmare to tablet manufacturers, leading to large-scale recalls of drug with defects in tablets.

●Causes of Tablet Black Spots

◌Raw Material Issues: Certain active pharmaceutical ingredients (API) are dark powders or granules. If the pre-production mixing is inadequate, resulting in localized high concentrations, affected areas appear as black spots in tablet manufacturing process. Next, some excipients such as sugars or polymers are heat-sensitive. During drying, if the temperature is out of control, charred black spots form on compressed tablets.

◌Tablet Press Issues: Punches and dies of a tablet compressor are metal tooling. Prolonged use can generate micron-level metal wear particles that mix into the powder blend and are compressed into pharmaceutical tablets, appearing as black spots. Additionally, insufficient cleaning of hoppers or feed pipes leaves residual powder from previous tablet manufacturing process which become black spots in a new batch of medication tablets.

◌Manual Lubrication: During manually lubricating a pill press tablet press machine, operators struggle to precisely control the lubricant amount. Any slight amount deviation results in excessive lubricant applied to areas such as punches and dies. Excess lubricant is then squeezed out during high-speed rotation of a pill and tablet press, splashing onto tablet granules, powder, or already formed medication tablets, giving rise to dark or black spots inside or on the surface of compressed tablets.

●Solutions to Spotted Defective Tablets

◌Controlling Raw Materials and Tablet Machines: Perform microbial and impurity limit testing on each batch of active pharmaceutical ingredients and excipients. Utilize magnetic separators and vibrating screens to sieve raw materials and remove iron impurities in tablet materials. Moreover, establish an maintenance plan of your automatic tablet press machine, and regularly inspect and polish punches and dies.

◌Optimizing Tablet Manufacturing Process: Determine the optimal mixing time through process validation to ensure uniform blending of tablet materials. For colored medication tablets, technologies like Near-Infrared can be utilized for monitoring blend uniformity. In addition, establish Standard Operating Procedures (SOPs) for cleaning tablet presses.

◌Being Equipped with Intelligent Lubrication: It can adjust in real-time based on rotational speed of a rotary tablet press, and deliver a microliter-level precise amount of lubricant before each tablet compression cycle, eliminating scenarios that excessive lubricant splashes onto tablet ingredients and results in black spots. Data shows intelligent lubrication system not only reduces lubricant consumption by up to 30% but also decreases tablet machine failures caused by manual lubrication by over 50%. Through predictive maintenance, intelligent lubrication provides more stable tablet pressing cycles and extended lifespan of a pill press tablet press machine.

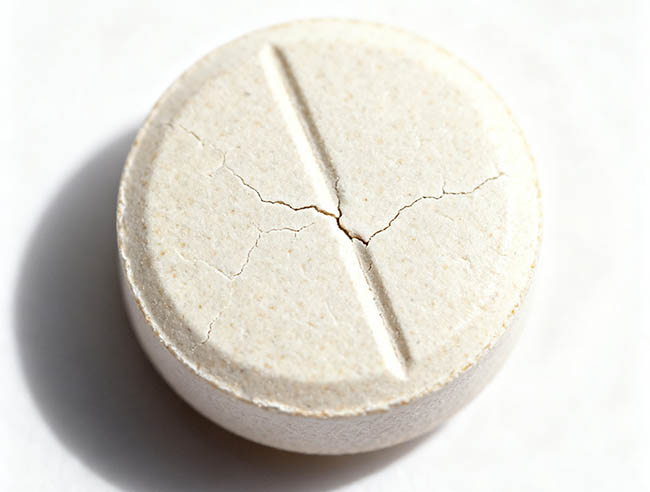

2. Cracking and Chipping

Besides tablet black spots, in tablet pressing process, cracking and chipping are another issues, with cracking refering to cracks on the surface or inside defective tablets, while chipping denoting the breaking or flaking at tablet edges. Both are common tablet defects that affect appearance and integrity of compressed tablets.

●Common Reasons

In the aspect of ingredient formulation

◌Insufficient Binder: It leads to weak cohesion between particles, making drug tablets prone to breakage at weak points during tablet production.

◌Excessive Amount of Fine Powder: Excessive fine powder acts like tiny, irregularly shaped balls which don’t pack well, creating many voids and a high volume of air within the powder bed. This poor packing leads to a tablet structure inherently less sturdy, more prone to breakage.

In the aspect of tablet maker machine operation

◌Insufficient Pressure: The force of main pressing is low, or the powdery or granular fill depth is excessive, resulting in inadequate tablet pressing.

◌Lack of Pre-compression: The absence of pre-compression fails to remove air within tablet granules, resulting in defective tablets with weak internal structures.

◌Excessive Speed: An overly high tablet pressing speed prevents powdery or granular particles from having enough time to bond effectively, causing elastic recovery that leads to soft tablets.

◌Pill Tablet Press Wear: Worn punches lead to uneven tablet pressing force distribution, compromising a tablet’s overall hardness.

●Solutions to Cracked Pills and Chipping

◌Optimizing the Formulation: Appropriately increase the amount of binder (e.g., HPMC, PVP) or select more efficient binders to enhance inter-particle bonding.

◌Improving Granule Quality: Reduce the proportion of fine powder by granulation optimization, such as using high-shear granulation, and implement strict sieving. This ensures uniform particle size and good flowability of tablet materials, promoting even pressure distribution.

◌Increase Tablet Compression Pressure: Gradually increase the main force of tablet pressing. Note that pressure cannot be increased indefinitely, as it may make pharmaceutical tablets too hard.

◌Optimize Pre-compression: Select a tablet pill press machine equipped with pre-compression function. Appropriately increase the pre-compression pressure of your rotary tablet press machine to 10%—30% of the main pressure to better remove air in tablet materials. Pre-compression gently removes up to 90% of the air from tablet granules or powder, according to Pharmaceutical Tableting Technology, before the main pill compression, elevating the plasticity of tablet materials. Investing in an automatic pill press with pre-compression is a fundamental process optimization that boosts tablet production capacity, making it a wise choice at the start for manufacturing tablets with zero tablet defects.

◌Adjusting Parameters: Properly reduce the tablet compression speed to allow sufficient time for granule or powder filling and air escape. Optimize the pre-compression and main compression forces of your pill press tablet press machine to achieve gradual pill compaction.

◌Equipment Check: Ensure punches and dies are not worn, and that no residual powder is affecting your tablet manufacturing process.

3. Excessive Residual Powder on Turret

During manufacturing tablets, the turret surface of a pill press tablet press machine often accumulates a layer of excess powder, ruining the hygiene condition.

This powder accumulation is primarily caused by the powder’s airborne nature, the centrifugal force of a turret’s rotary motions, and minor electrostatic adsorption. If not removed, residual powder cannot only cause cross-contamination but also seep into mold gaps, accelerating wear of an automatic tablet making machine.

To address this tableting defect, the dust extraction system and the feed frame are two key components.

◌A dust extraction system acts like a faithful cleaner, and uses negative pressure airflow to continuously remove airborne dust, maintaining a clean environment for drug tablet compression.

◌A feed frame functions like a precise guardian with its edge fitting closely to the turret surface. In a tablet compression process, before upper punches enter die cavities, tablet powder may be thrown out due to centrifugal force. A feed frame is designed to cover the distance from a forced feeder to the point where upper punches get into die bores, and direct excessive powder into a copper pan. Powdery ingredient is then returned to the feeder via the copper pan, enabling recycling of tablet materials.

Beyond solutions above, regular manual cleaning, using anti-static coatings to reduce powder adhesion, and optimizing the powder formulation to minimize dust generation are auxiliary measures for controlling residual powder on a turret of a rotary tablet pill making machine.

4. Waste of Tablet Materials

During the tablet compression process, excessive powder leaking from the feeder gaps not only wastes tablet materials but also accumulates powder on turret of your tablet making machine pill press, affecting cleanliness and operation.

The Excess Powder Recycling System addresses this issue. Its integrated reclaiming turret utilizes the main turret’s drive to automatically recover this otherwise wasted powder, redirecting it back into the tablet compression process for reuse.

This system delivers two core advantages:

●Significant Cost Reduction: Based on Ruidapacking’s internal production line data, the system achieves over 99% recovery rate for excess powder, minimizing tablet material waste and generating substantial cost savings.

●Cleaner Production: This system reduces powder accumulation on the turret surface, keeping a press tablet machine cleaner, lowering cross-contamination risks.

Choosing a pill machine tablet press with an excess powder recycling system means embracing a cost-saving and cleaner tablet compression philosophy. For example, the HGZP 26—40D from Ruidapacking is an intelligent tablet pill press designed for Industry 4.0. This automated tablet machine integrates advanced features including an excess powder recycling system, pre-compression, dual dust extraction, an intelligent lubrication system, tool-free tooling changeover, automatic powder fill adjustment, pressure monitoring, and automatic rejection of tablets with unqualified weight.

This high-output pill and tablet press is built for large-scale tablet compression, achieving a maximum output of 260,000 tablets per hour, capable of handling various pill shapes, such as round, irregular-shaped, double-layer, and ring-shaped tablets, with a max diameter of 25mm. With a robust pre-compression force of 20kN and a main force of 100kN, this automated tablet machine is suitable for compressing challenging and corrosive tablet materials into pills.

5. Time-Costing Tooling Changeover

Traditional pill tablet presses mold changes are a tough job, often requiring hammers to force parts in and out. This tooling changeover not only takes over two hours but also damages the precision of pill presser molds over time.

Nowadays, advanced compression tablet machines allow for tool-free mold replacement including dies and upper, lower punches. A representative example is Ruidapacking’s HZP 15—20D automatic tablet press machine, which completes mold changeover in just 30 minutes, saving at least 2 hours per change. If molds are changed weekly, this saves 100 hours annually (1 year contains 50 weeks). With an output of 90,000 tablets per hour, this efficiency gain potentially adds 9 million extra tablets to yearly tablet manufacturing.

This advanced feature comes from the high precision and perfect fit between the turret and molds, ensuring a seamless, tool-free mold changeover. It’s a smarter way to maintain your pharmaceutical compression tablet machine.

Τελικές γραμμές

Avoiding tableting defects and optimizing tablet compression require a holistic approach that addresses both mechanical precision and process control. By systematically tackling common issues from black spots and chipping to residual powder and manual lubrication, tablet manufacturers can significantly enhance tablet integrity and pill press efficiency. Embracing advanced solutions, such as automated lubrication and rapid tooling changeover, not only resolves specific tableting defects but also elevates overall tablet production performance.