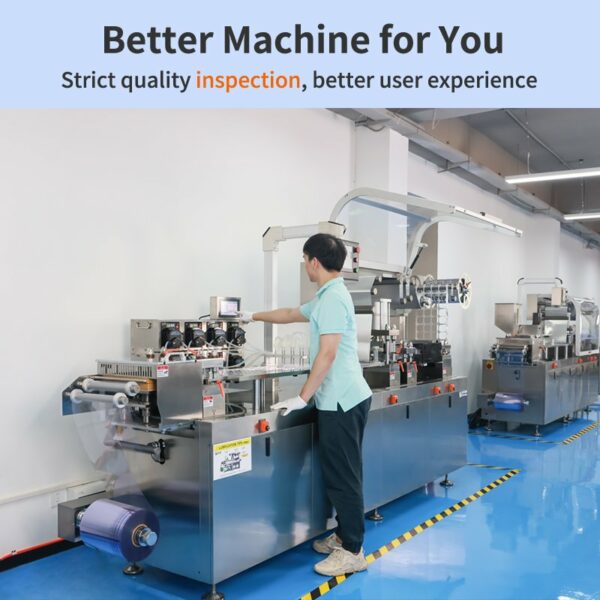

DPP-270L Saucen-Blisterverpackungsmaschine

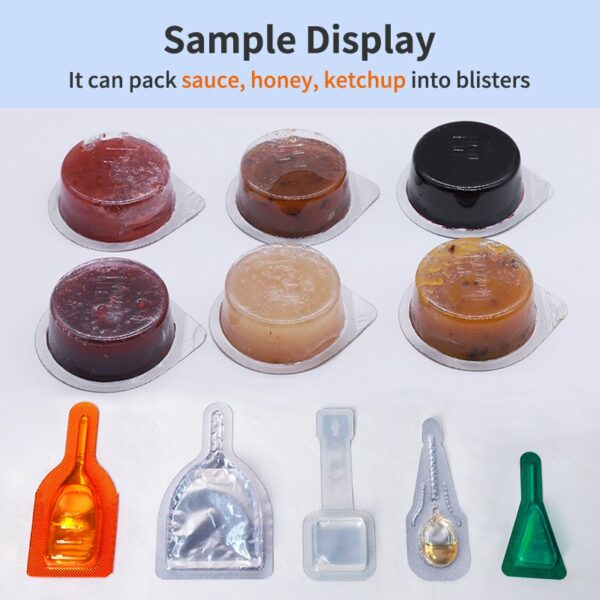

DPP-270L Soßenblisterverpackungsmaschine ist zum Verpacken flüssiger Produkte (wie Sirup, Öl oder Cremes) in einzelne Blisterpackungen bestimmt.

Erhitzen und Formen: Die Folie wird auf eine bestimmte Temperatur erhitzt, um sie weich und biegsam zu machen. Anschließend gelangt sie in eine Formstation, wo sie mithilfe von Formen zu einzelnen Blistertaschen geformt wird. Mithilfe von Vakuum oder Luftdruck werden Hohlräume geformt, die das flüssige Produkt aufnehmen.

Dosiermechanismus: Dieser kann eine Pumpe, eine Düse oder ein volumetrisches System umfassen, um sicherzustellen, dass jede Blase genau mit der richtigen Flüssigkeitsmenge gefüllt wird.

Versiegelungsprozess: Die gefüllten Blisterpackungen durchlaufen eine Versiegelungsstation, wo Hitze und Druck die Deckelfolie mit der Bodenfolie verbinden. Dadurch entsteht eine versiegelte Hülle, die das flüssige Produkt vor Verunreinigung, Auslaufen oder Verderben schützt.

Schneiden: Nach dem Versiegeln schneidet die Maschine den Endlosstreifen der Blister in einzelne Packungen.

Spezifikation:

Bis zu 9600 Platten/h

Geeignet für Parfüm, Marmelade, Honig …

Geeignet für PVC-, PS- und PET-Material