স্টিক ফিলিং মেশিন দানাদার, গুঁড়ো, তরল, পেস্ট এবং কঠিন পণ্য (যেমন, স্ন্যাকস, ক্যান্ডি, পোষা প্রাণীর খাবার, ডিটারজেন্ট, মশলা) এর প্যাকেজিং স্বয়ংক্রিয়ভাবে আগে থেকে তৈরি, স্ট্যান্ড-আপ পাউচে (বালিশের ব্যাগ, 3/4-সাইড সিল ব্যাগ) ফিল্মের একটি অবিচ্ছিন্ন রোল থেকে তৈরি করে।

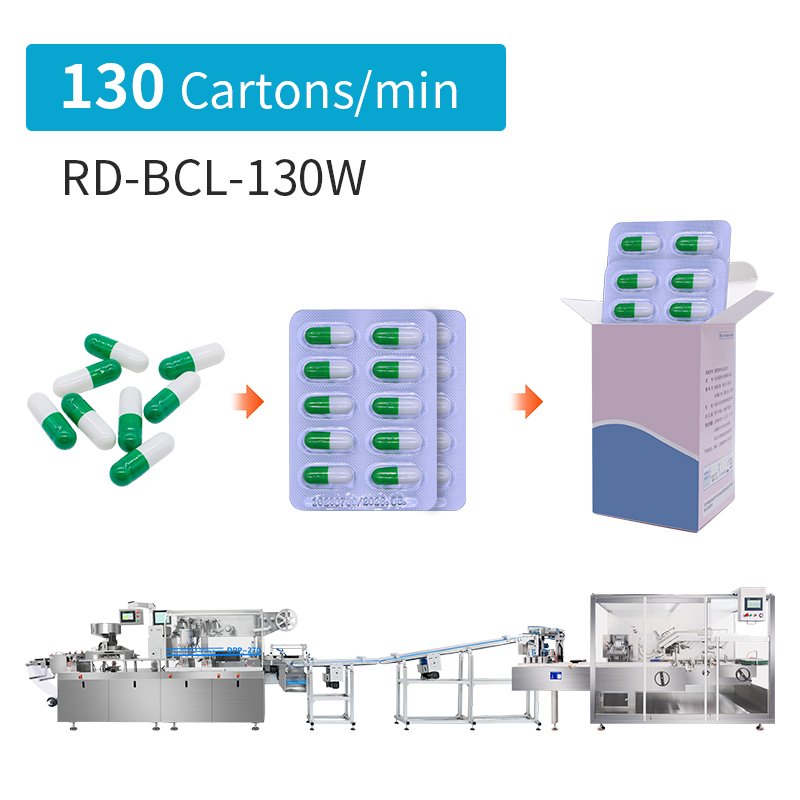

রুইডা প্যাকিংয়ের RD-SPM-480 6-লেন ব্যাক সিলড স্যাচে প্যাকিং মেশিনটি উচ্চ-গতির ফার্মাসিউটিক্যাল পাউডার প্যাকেজিংয়ের জন্য একটি নতুন মানদণ্ড স্থাপন করে। GMP-সম্মত ইঞ্জিনিয়ারিংয়ের সাথে সার্ভো নির্ভুলতার সমন্বয়ে, এই সিস্টেমটি ফিল্ম আনওয়াইন্ডিং থেকে চূড়ান্ত পণ্য নিষ্কাশন পর্যন্ত অতুলনীয় নির্ভুলতা প্রদান করে। কঠোর নিয়ন্ত্রক মান পূরণ করে এটি কীভাবে ±0.1% ডোজিং নির্ভুলতা অর্জন করে তা এখানে দেখানো হয়েছে।

1. কাজের নীতি

১.১ ফিল্ম আনওয়াইন্ডিং এবং টেনশন নিয়ন্ত্রণ

মেশিনের আনওয়াইন্ড শ্যাফ্টে বহু-স্তরযুক্ত প্যাকেজিং ফিল্মের একটি রোল (PET/PE, OPP/CPP, Alu/PE) লাগানো থাকে। একটি টেনশন কন্ট্রোল সিস্টেম (ব্রেক, সেন্সর, ড্যান্সার রোল) বলিরেখা, প্রসারিত বা শিথিলতা রোধ করার জন্য স্থির, সর্বোত্তম ফিল্ম টেনশন বজায় রাখে।

১.২ ফিল্ম গাইডেন্স এবং প্রিন্টিং (ঐচ্ছিক)

ফিল্মটি গাইড রোলারের মধ্য দিয়ে যায়, যা গঠন অংশে মসৃণ, সারিবদ্ধ প্রবেশ নিশ্চিত করে। প্রয়োজনে, একটি তারিখ/ব্যাচ কোড প্রিন্টার (তাপীয় স্থানান্তর, ইঙ্কজেট, রিবন) ফিল্মটিকে একটি সুনির্দিষ্ট স্থানে চিহ্নিত করে।

১.৩ ফিল্ম গঠন

এই নির্ভুল ধাতুটি ফিল্মটিকে ভাঁজ/বাঁকিয়ে একটি অবিচ্ছিন্ন, উল্লম্ব নলের আকার দেয়। ফিল্মের প্রান্তগুলি হয় ওভারল্যাপিং বা বাটিং অবস্থায় অবস্থিত, অনুদৈর্ঘ্য সিলের জন্য প্রস্তুত।

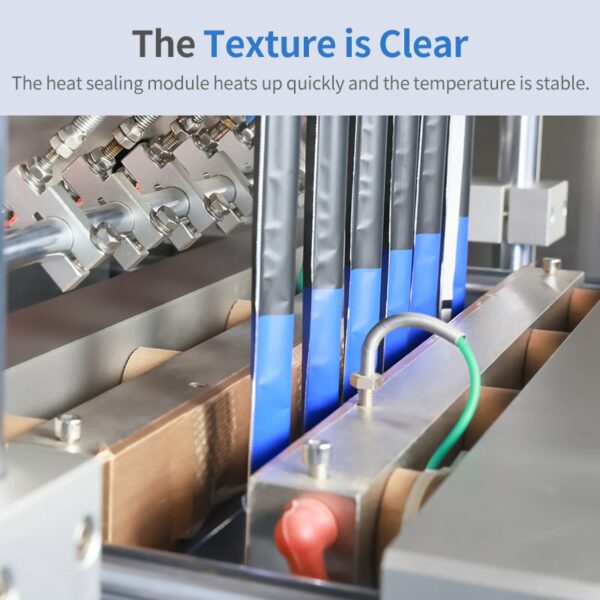

১.৪ অনুদৈর্ঘ্য (উল্লম্ব) সিলিং

গঠনের পরপরই, ওভারল্যাপিং ফিল্মের প্রান্তগুলি অনুদৈর্ঘ্য সিলারের মধ্য দিয়ে যায়। উত্তপ্ত বেল্টগুলি নিয়ন্ত্রিত তাপ, চাপ এবং স্থায়ী সময় প্রয়োগ করে। ফিল্মের অভ্যন্তরীণ তাপ-সীল স্তরটি গলে যায়, একটি শক্তিশালী, অবিচ্ছিন্ন ব্যাক সিল তৈরি করে (সমাপ্ত ব্যাগের একপাশে)।

১.৫ পণ্য ভর্তি

সিল করা ফিল্ম টিউবটি নিচের দিকে চলতে থাকে। অনুদৈর্ঘ্য সিল পয়েন্টের নীচে, সার্ভো স্ক্রু (ফর্মিং কলার সহ সমঅক্ষ) একটি পূর্ব-পরিমাপিত পণ্যের ডোজ স্যাচেটে বিতরণ করে। ডোজিং অগারের মাধ্যমে করা হয়। মাধ্যাকর্ষণ পণ্য প্রবাহকে সহায়তা করে। দূষণ এড়াতে সিলের নীচে ভর্তি করা হয়।

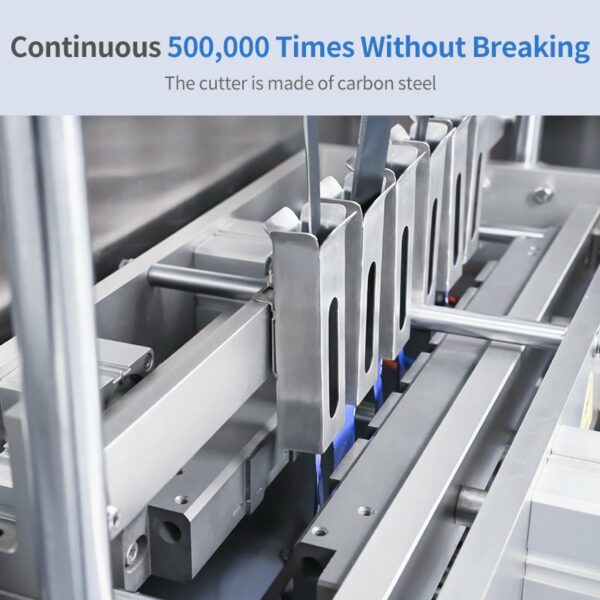

১.৬ ট্রান্সভার্স সিলিং এবং কাটিং

চোয়ালগুলো শক্ত করে চেপে ধরে, তাপ এবং চাপ প্রয়োগ করে। একসাথে দুটি সিল তৈরি করে। নীচের ব্যাগের উপরের সিল (ভরা হচ্ছে)। উপরের ব্যাগের নীচের সিল (সবেমাত্র ভরা)। চোয়ালের মধ্যে সংযুক্ত একটি ব্লেড (গরম ছুরি, দানাদার, ঠান্ডা কাটা) এই দুটি সিলের মধ্যের ফিল্মটি ছিঁড়ে ফেলে। এটি সমাপ্ত উপরের ব্যাগটিকে আলাদা করে এবং পরবর্তী ভর্তির জন্য নীচের ব্যাগটি উপরের দিকে খোলা রাখে।

১.৭ সমাপ্ত ব্যাগ স্রাব

আলাদা করা, সিল করা ব্যাগগুলি সংগ্রহ বা ডাউনস্ট্রিম প্রক্রিয়াকরণের জন্য দূরে নিয়ে যাওয়া হয় (চেকওয়েজার, মেটাল ডিটেক্টর, কার্টনিং প্যাকিং).

2. সুবিধা

২.১ উচ্চ দক্ষতা এবং অবিচ্ছিন্ন অপারেশন

ক্রমাগত রোল ফিল্ম ব্যবহার করে, আগে থেকে তৈরি ব্যাগের ঘন ঘন থামার সম্ভাবনা কমিয়ে দেয়। খুব উচ্চ গতি (প্রায়শই ২০০+ ব্যাগ/মিনিট), ব্যাপক উৎপাদনের জন্য আদর্শ।

২.২ নমনীয় থলির ধরণ

টুলিং পরিবর্তন সহ 3-পার্শ্ব সীল এবং 4-পার্শ্ব সীল ব্যাগ তৈরি করতে পারে। সামঞ্জস্যযোগ্য থলির দৈর্ঘ্য এবং প্রস্থ (কলার পরিবর্তনের মাধ্যমে)।

২.৩ ব্যাপক উপাদানের সামঞ্জস্য

বিভিন্ন স্তরিত রোল ফিল্ম পরিচালনা করে: একক/বহু-স্তর প্লাস্টিক, ধাতব ফিল্ম, অ্যালুমিনিয়াম ল্যামিনেট, কাগজের কম্পোজিট। বিভিন্ন বাধা, শক্তি, মুদ্রণ এবং সিলের প্রয়োজনীয়তা পূরণ করে।

২.৪ বিস্তৃত পণ্য প্রযোজ্যতা

বিভিন্ন ধরণের প্যাকেজ: দানাদার, গুঁড়ো, তরল, পেস্ট, কঠিন পদার্থ, ফ্লেক্স, খণ্ড। ফার্মা (পাউডার), খাদ্য (স্ন্যাকস, হিমায়িত পণ্য, কফি, মশলা), এফএমসিজি (ডিটারজেন্ট, নমুনা), পোষা প্রাণীর খাবার, হার্ডওয়্যার এবং রাসায়নিক দ্রব্যে ব্যাপকভাবে ব্যবহৃত হয়।

২.৫ উচ্চ অটোমেশন

ফিল্ম হ্যান্ডলিং, ফর্মিং, ফিলিং, সিলিং, কোডিং (ঐচ্ছিক), কাটিং এবং ডিসচার্জ সম্পূর্ণরূপে একীভূত করে। আপস্ট্রিম ফিডার (ওজন স্কেল, অগার ফিলার, তরল পাম্প) এবং ডাউনস্ট্রিম সিস্টেম (চেকওয়েগার, কেস প্যাকার) এর সাথে সহজেই একীভূত হয়।

২.৬ উপাদান এবং খরচ দক্ষতা

রোল ফিল্ম পূর্বে তৈরি থলির তুলনায় কম অপচয় উৎপন্ন করে। ফিল্ম রোলগুলির কম্প্যাক্ট স্টোরেজ এবং পরিবহন খরচ কমায়।

২.৭ নির্ভরযোগ্য সিলিং

নিয়ন্ত্রিত তাপ, চাপ এবং সময় পণ্য সুরক্ষা এবং বর্ধিত শেলফ লাইফের জন্য শক্তিশালী, বায়ুরোধী অনুদৈর্ঘ্য এবং অনুপ্রস্থ সীল নিশ্চিত করে।

২.৮ আলোক-ইলেকট্রিক মার্ক অ্যালাইনমেন্ট

আমাদের উচ্চ-রেজোলিউশনের অপটিক্যাল সেন্সরগুলি ২০০ স্ক্যান/সেকেন্ডে রেজিস্ট্রেশন মার্ক স্ক্যান করে। এটি ক্লোজড-লুপ ফিডব্যাককে রিয়েল-টাইমে গতিশীলভাবে ফিল্মের অবস্থান সামঞ্জস্য করতে সক্ষম করে:

আপোষহীন অবস্থানগত নির্ভুলতা: প্রিন্ট গ্রাফিকের ধারাবাহিকতা বজায় রেখে টিয়ার নচগুলি ±0.3 মিমি সহনশীলতার মধ্যে সারিবদ্ধ হওয়া নিশ্চিত করে।

শূন্য উপাদানের অপচয়: ভুল সারিবদ্ধকরণ-সম্পর্কিত ফিল্ম প্রত্যাখ্যান দূর করে।

প্রক্রিয়া নির্ভরযোগ্যতা: প্রতিটি থলির কার্যকারিতা এবং নান্দনিক বৈশিষ্ট্য একই রকম বজায় রাখার নিশ্চয়তা দেয়।

৩. সীমাবদ্ধতা

পণ্যের সীমাবদ্ধতা: খুব লম্বা, ভারী, ভঙ্গুর, সহজে চূর্ণবিচূর্ণ, অথবা অত্যন্ত অনিয়মিত আকারের জিনিসপত্রের জন্য কম উপযুক্ত যা টিউব বা ফিলারে জ্যাম হতে পারে।

পরিবর্তনের জটিলতা: থলির প্রস্থ পরিবর্তনের জন্য ফর্মিং কলার প্রতিস্থাপন করতে হয়, যার মধ্যে ডাউনটাইম এবং অপারেটর দক্ষতা অন্তর্ভুক্ত থাকে।

প্রাথমিক বিনিয়োগ: সাধারণ ম্যানুয়াল/সেমি-অটো মেশিনের তুলনায় উচ্চতর প্রাথমিক খরচ।

ফিল্মের গুণমান নির্ভরতা: ধারাবাহিক, উচ্চ-মানের ফিল্ম রোল স্টক প্রয়োজন। নির্ভরযোগ্য অপারেশনের জন্য মুদ্রণ নিবন্ধন, টান নিয়ন্ত্রণ এবং সিল স্তরের কর্মক্ষমতা অত্যন্ত গুরুত্বপূর্ণ।

স্টিক প্যাক ফর্ম ফিল সিলিং মেশিনটি তাদের অনন্য উল্লম্ব টিউব-গঠন, ভর্তি এবং সিলিং প্রক্রিয়ার মাধ্যমে স্ট্যান্ড-আপ পাউচের উচ্চ-গতির, স্বয়ংক্রিয় উৎপাদনে উৎকর্ষ সাধন করে। মূল শক্তিগুলির মধ্যে রয়েছে দক্ষতা, পাউচ বহুমুখীতা (বিশেষ করে স্ট্যান্ড-আপ ক্ষমতা), বিস্তৃত উপাদান/পণ্যের সামঞ্জস্য, অটোমেশন এবং উপাদান সাশ্রয়। নির্বাচনের জন্য পণ্যের সুনির্দিষ্টতা, উৎপাদনের পরিমাণ, ফিল্মের ধরণ, বাজেট এবং অটোমেশনের প্রয়োজনীয়তাগুলি সাবধানতার সাথে বিবেচনা করা প্রয়োজন।