At Ruidapacking, we believe that the most successful partnerships are forged not just by selling machinery, but by providing comprehensive solutions to our clients’ most pressing production challenges. This philosophy was vividly demonstrated during CPHI Shenzhen in Sep 2025, where our Sales Manager, Mary, engaged with Abdullah, a representative from a prominent nutraceutical company in Jordan. The detailed discussions that followed, centered on Abdullah’s specific operational hurdles, ultimately led to ruidapacking being selected as a trusted supplier. This case study outlines how a focused, solution-oriented dialogue built confidence and secured a valuable international partnership.

Introduction: A Meeting of Minds at a Global Platform

International trade fairs like CPHI serve as crucial convergence points for industry leaders. For Abdullah, seeking to upgrade his company’s solid dose manufacturing capabilities, the event was an opportunity to find reliable partners. For Mary and ruidapacking, it was a chance to demonstrate expertise beyond product specifications. Their meeting transitioned quickly from a standard sales pitch to a deep-dive technical consultation. Abdullah, an experienced professional, came with a clear list of pain points from his existing tablet press and capsule filling machines. His detailed understanding of the problems allowed Mary to craft a highly specific and compelling proposal on the spot.

1. Solving the Tablet Press Puzzle

Abdullah’s primary concern was his underperforming tablet press. The issues were multifaceted: low output, severe die corrosion, a chaotic PLC control system, and difficult maintenance procedures.

1.1. Low Production Output and Molds Corrosion

Abdullah’s existing machine could not keep up with demand, capping production at an inefficient rate. Furthermore, the high sugar content in their effervescent and nutraceutical tablets was causing accelerated corrosion of the standard tooling, leading to frequent replacements, product contamination risks, and downtime.

Solution: The HGZP-26D Tablet Press with Customized, Corrosion-Resistant Tooling

Mary immediately recommended the HGZP-26D tablet press machine, a robust model capable of a high output of 170,000 tablets per hour, directly addressing the production bottleneck. To tackle the corrosion issue head-on, Mary proposed a custom tooling solution. Instead of standard materials, the upper, lower punches and middle dies would be manufactured from solid 316L stainless steel bar stock—known for its superior corrosion resistance. As an additional protective layer, the tooling surfaces would be chrome-plated. This specialized approach significantly extends the lifespan of the tooling in abrasive and corrosive environments, ensuring product security and reducing long-term operational costs.

1.2. Inefficient PLC System and Cumbersome Maintenance

The existing machine’s PLC system was unstructured, allowing unauthorized personnel to alter critical parameter, which led to inconsistencies and quality issues. Maintenance, particularly die changes, was a laborious process requiring tools like hammers, increasing the risk of damage and operator injury.

Solution: Structured Password Protection and Precision Engineering for Easy Maintenance

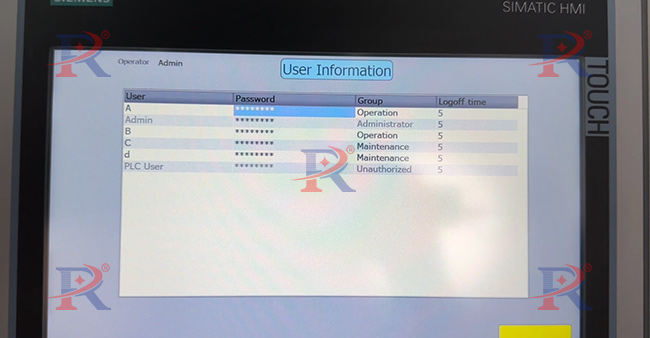

Understanding the need for operational control, ruidapacking designed a three-tiered password protection system for the PLC:

Manager Level: Access to all data logs and system parameters.

Technician Level: Permission to adjust essential settings like production speed, filling depth, and pressure.

Operator Level: Restricted to basic functions—start/stop and feeding—preventing unintended changes that could disrupt production.

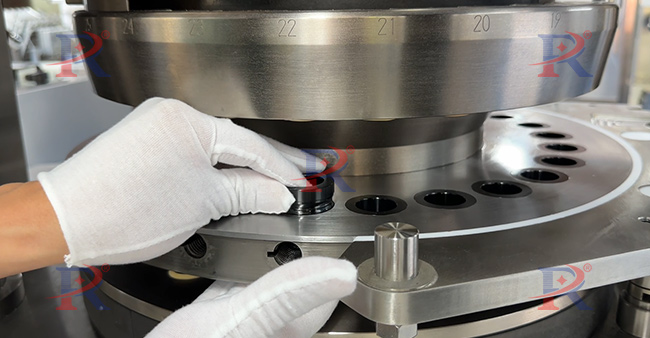

For maintenance, Mary emphasized the precision engineering of the HGZP-26D. The turret and dies are manufactured using CNC machining to exacting tolerances. This precision allows for dies to be changed by hand, effortlessly, without tool. A complete die changeover, a task that previously caused significant downtime, can now be accomplished safely and efficiently in just 30 minutes.

2. Ensuring Capsule Filling Machine Stability and Streamlining Changeovers

Abdullah’s challenges extended to his capsule filling operation, which suffered from instability and difficult mold changes.

2.1. Frequent Stoppages and Difficult Mold Changes

The existing capsule machine could not run continuously for more than an hour without a stoppage, severely impacting overall equipment effectiveness (OEE). Additionally, changing molds for different capsule sizes was a complex and time-consuming ordeal.

Solution: Proven Stability and Modular Design for Rapid Change Molds

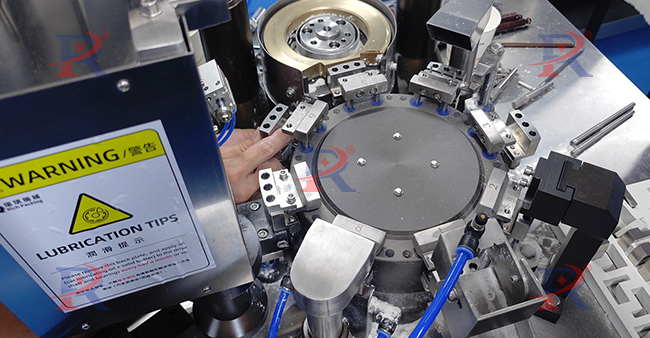

Mary confidently guaranteed the continuous operational stability of ruidapacking’s capsule filling machines. To substantiate this claim, she arranged a live video verification session post-fair. Our engineering team ran a machine non-stop for four hours, demonstrating flawless performance under Abdullah’s direct observation. This transparency eliminated doubts about reliability, showcasing a machine that would save substantial manpower and boost productivity.

Regarding change molds difficulties, Mary highlighted the machine’s modular design. Through a live video call with our workshop, an engineer demonstrated a step-by-step mold change procedure. Abdullah could see firsthand how the intuitive, modular components allowed a full mold change to be completed within 30 minutes, a dramatic improvement over his maintennace process. This visual proof effectively dismantled his final reservations.

Trust Built on Transparency and Tangible Solutions

Abdullah have a strong impression of ruidapacking as a solution provider, not just a vendor. The combination of specific machine recommendations, custom engineering adaptations, transparent live demonstrations, and a clear focus on solving his unique problems made a decisive impact.

This experience with Abdullah reinforces our core belief at ruidapacking: by adopting a mindset dedicated to solving client problems, we build lasting trust. Even when a deal is not immediately finalized, the impression of professionalism and attitude ensures that when the client is ready to purchase, Ruidapacking will be the preferred choice. We are confident that this partnership with Abdullah’s company is the beginning of a long and successful collaboration, solidifying our reputation in the Jordanian market and beyond as a leader in pharmaceutical and packaging machinery solutions.