เครื่องบรรจุกล่องแบบโหลดด้านข้าง

เครื่องบรรจุกล่องด้านข้างเป็นอุปกรณ์สำคัญที่ใช้ในกระบวนการบรรจุภัณฑ์ ออกแบบมาเพื่อสร้าง บรรจุ และปิดผนึกกล่องโดยอัตโนมัติสำหรับผลิตภัณฑ์หลากหลายประเภท รวมถึงยา อาหาร เครื่องสำอาง และสินค้าอุปโภคบริโภค นอกจากนี้ยังสามารถเชื่อมต่อกับสายการผลิตได้ เครื่องบรรจุภัณฑ์แบบฟอยล์กันชื้น และเครื่องบรรจุหมอน.

เครื่องบรรจุกล่องสามารถจัดการกับขนาดและรูปแบบของกล่องได้หลากหลาย รวมถึงกล่องพับได้ กล่องแสดงสินค้า และกล่องรูปทรงพิเศษ โดยทั่วไปแล้วเครื่องจะทำงานในลักษณะต่อเนื่องหรือเป็นช่วงๆ ซึ่งช่วยให้สามารถผลิตได้อย่างรวดเร็วในขณะที่ยังคงความแม่นยำในการจัดวางผลิตภัณฑ์และการปิดผนึก.

กระบวนการโดยทั่วไปเกี่ยวข้องกับการป้อนกล่องแบนเข้าไปในเครื่อง ซึ่งกล่องจะถูกขึ้นรูปเป็นรูปทรงสามมิติ เติมผลิตภัณฑ์ และปิดผนึก โดยมักใช้กาวหรือการปิดฝากล่องแบบสอดทับกัน รุ่นขั้นสูงมีระบบควบคุมคุณภาพแบบบูรณาการ เพื่อให้มั่นใจในการบรรจุที่ถูกต้องและการปิดผนึกที่แน่นหนาเพื่อป้องกันการงัดแงะหรือการปนเปื้อนของผลิตภัณฑ์.

ด้วยความสามารถในการรองรับความต้องการบรรจุภัณฑ์ที่หลากหลาย เครื่องบรรจุกล่องจึงเป็นสิ่งจำเป็นสำหรับธุรกิจที่ต้องการเพิ่มประสิทธิภาพการดำเนินงานด้านบรรจุภัณฑ์ พร้อมทั้งรักษาความสมบูรณ์ของผลิตภัณฑ์และปฏิบัติตามมาตรฐานอุตสาหกรรม.

ข้อมูลจำเพาะ:

สูงสุด 120 กล่อง/นาที

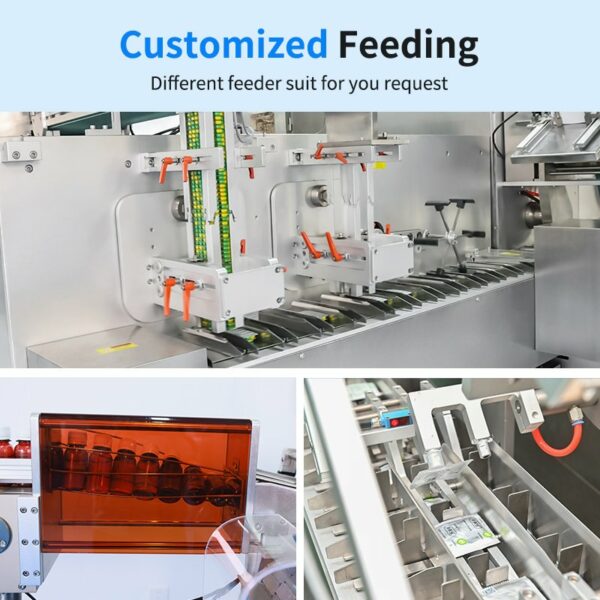

ใช้ได้กับจานบิสเตอร์ ขวด ซอง ฯลฯ

จัดส่งรวดเร็วภายใน 15 วัน