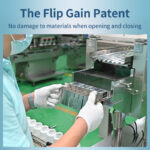

เครื่องนับและบรรจุขวด

Counting and filling bottle machine involves controlled feeding, sensors for capsule detection, accurate counting, capsule bottling. Suit for pharmaceutical, chemical, health care products and other industries.

ข้อมูลจำเพาะ:

สูงสุด 70 ขวด/นาที

อัตราความแม่นยำ > 99.8%

จัดส่งรวดเร็วภายใน 7 วัน

เหมาะสำหรับแคปซูล/เม็ด/กัมมี่ ขนาด 3-25 มม.