Трехслойная таблеточная машина

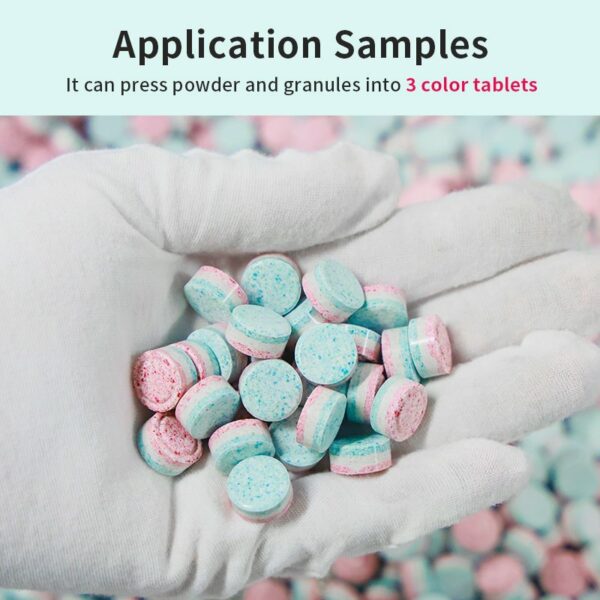

Трехслойная таблеточная машина предназначен для производства таблеток с тремя отдельными слоями, обычно используется для создания таблеток с различными профилями высвобождения лекарственных средств или комбинациями активных ингредиентов.

Отдельные бункеры: машина оснащена тремя независимыми бункерами, каждый из которых содержит разный материал для соответствующего слоя. Материал каждого слоя подается в полость матрицы последовательно с помощью управляемых механизмов подачи, что обеспечивает равномерное распределение.

Первый слой: первый материал подается в полость матрицы и предварительно сжимается с помощью предварительного прессующего ролика. На этом этапе формируется компактный базовый слой без полного сжатия, готовый к склеиванию со вторым слоем.

Второй слой: Второй материал наносится поверх первого слоя и снова предварительно сжимается, чтобы обеспечить адгезию и избежать расслоения.

Третий слой: вводится третий материал, завершая процесс наложения слоев, а окончательное предварительное сжатие обеспечивает надлежащее соединение всех слоев.

Спецификация:

До 395 000 шт./ч

Макс. диаметр таблетки 50 мм