What is A Liquid Bottle Filling Machine

Liquid filler machine are the automated workhorses of packaging lines, engineered to dispense precise volumes of liquid products, from life-saving vaccines to daily-use shampoos, into containers at industrial speeds. They eliminate human error in dosing, prevent costly product waste (up to 20% in manual operations), and ensure batch-to-batch consistency critical for regulated industries. In pharmaceutical packaging alone, filling accuracy determines drug efficacy and compliance with FDA 21 CFR Part 211 regulations.

How Liquid Filling Technology Works

Modern liquid fillers operate through integrated systems:

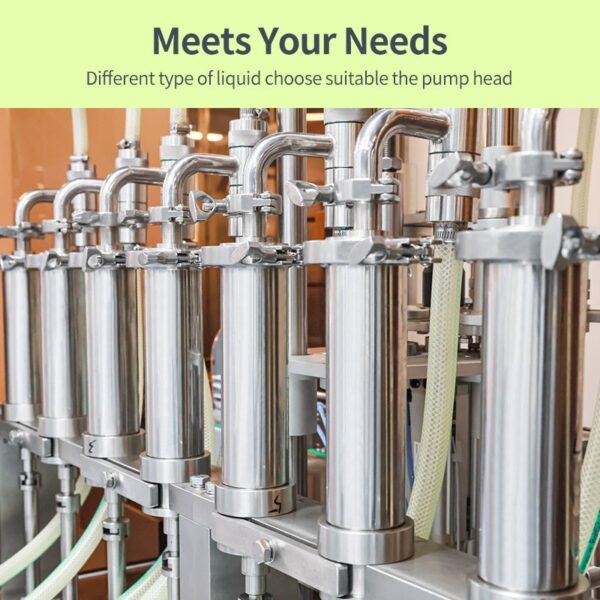

1. Material Handling: Pumps transfer liquid from bulk tanks to filling nozzles.

Piston Fillers: Ideal for viscous products (creams, sauces) using cylinder displacement

Peristaltic Pumps: For sterile applications; tubes prevent cross-contamination

Gravity Fillers: Cost-effective for free-flowing liquids (water, solvents)

Overflow Systems: Guarantee uniform fill levels for clear bottles

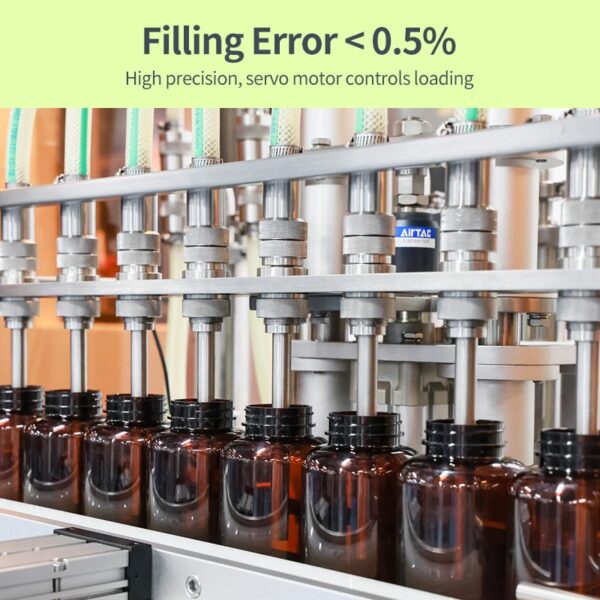

2. Container Positioning: Servo-driven conveyors index bottles under nozzles with ±0.1mm accuracy.

3. Dosing Phase: Nozzles descend, creating sealed environments. Sensors trigger:

Volumetric fills (pre-set cylinder volumes)

Net-weight fills (load cells for high-value liquids)

4. Anti-Drip Retraction: Nozzles lift with reverse suction, eliminating residue.

4 Factors Determining Fill Accuracy (±0.2% to ±1%)

| Factor |

Impact |

Optimization Strategy |

| Fluid Viscosity |

High-viscosity fluids (>10,000 cP) cause lag in drainage |

Use piston pumps + tapered nozzles; pre-heat thick products |

| Machine Calibration |

Wear in pump seals/valves causes drift |

Daily verification with check weights; ISO 9001 calibration schedules |

| Экологический контроль |

Temperature changes alter liquid density |

Install inline viscometers; ±1°C climate control |

| Operator Training |

Incorrect parameter settings induce errors |

Touchscreen HMI with recipe lock; IoT remote monitoring |

Pharma Case Study: A Pfizer contractor reduced vaccine overfill by 8.7% after switching to servo-piston fillers with real-time pressure compensation.

Surging Market Demand: Data-Driven Growth Projections

The global liquid filling machine market will reach $7.24 Billion by 2030 (Grand View Research, 2023), fueled by:

Pharma/Biotech Boom: 65% of new machines serve vaccine/syringe filling needs post-pandemic

Emerging Economies: India’s FMCG sector growing at 14% CAGR driving packaging automation

Regulatory Pressures: 90% of FDA warning letters cite “inadequate process controls” in filling.

5 Strategic Trends

1. Flexible Manufacturing

Example: Bosch’s modular fillers switch between 50ml vials and 1L bottles in 8 minutes via auto-adjusting grippers.

2. Industry 4.0 Integration

OPC-UA communication between fillers and MES systems.

Predictive maintenance using vibration/temperature sensors (↓30% downtime).

3. Sustainable Engineering

Energy recovery from servo deceleration (25% power savings).

Waterless cleaning with UV-C sterilization.

4. Hybrid Aseptic Systems

Isolator + RABS technology enabling Grade A fills without cleanrooms.

5. AI-Powered Optimization

Machine learning algorithms adjusting fills based on real-time viscosity data.

Industry-Specific Innovation Spotlight

Pharma: Blow-Fill-Seal (BFS) integrated systems for vial filling at 99.95% sterility.

Cosmetics: Multi-head fillers handling 8 product variants simultaneously.

Food: Hot-fill machines pasteurizing juices at 88°C during filling.

Chemicals: Explosion-proof fillers with ATEX certification.

As packaging becomes strategic to brand integrity and sustainability, choosing advanced liquid filling technology is non-negotiable. Leading manufacturers now prioritize:

Unified Control: Single HMI operating filling-capping-labeling.

Data Traceability: Blockchain-enabled batch logging.

Future-Proofing: Upgradeable software architectures.