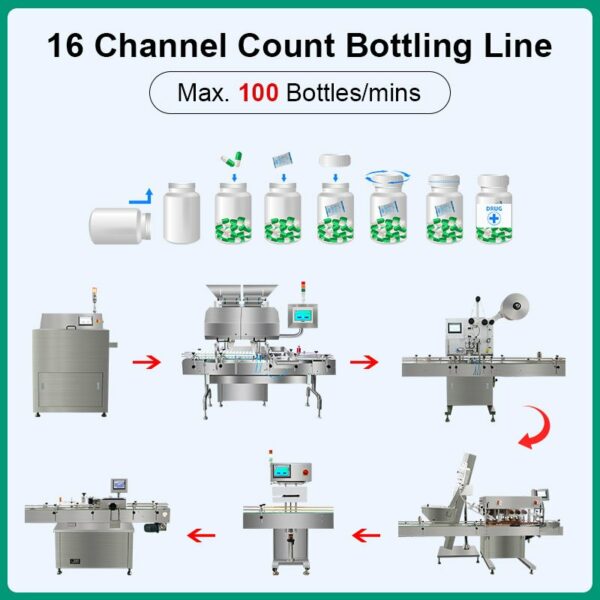

Capsule Bottling Line

Capsule bottling line components :

Bottle Unscrambler: Bottles are automatically fed into the line using a conveyor or rotary turntable.

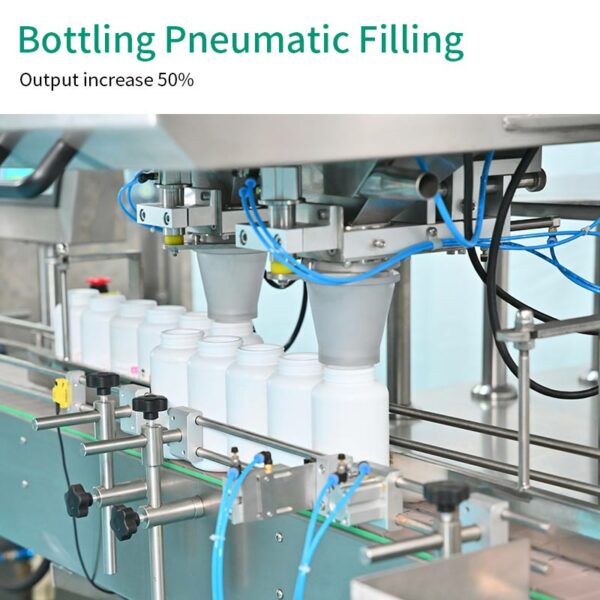

Counting Machine: Capsules are filled into bottles after counting.

Desiccant Inserter: Inserts desiccant packs into the bottles to maintain capsule stability and prevent moisture damage.

Capping Machine: Automatically caps the filled bottles to seal them.

Induction Sealing Machine: Seals the bottle with a foil layer to ensure tamper-evidence and preserve product freshness.

Labeling Machine: Applies labels to the bottles with product information, batch numbers, expiration dates, and barcodes.

Спецификация:

До 100 бутылок/мин

точность > 99.98%

Подходит для капсул/таблеток/жевательных конфет диаметром 3–40 мм.