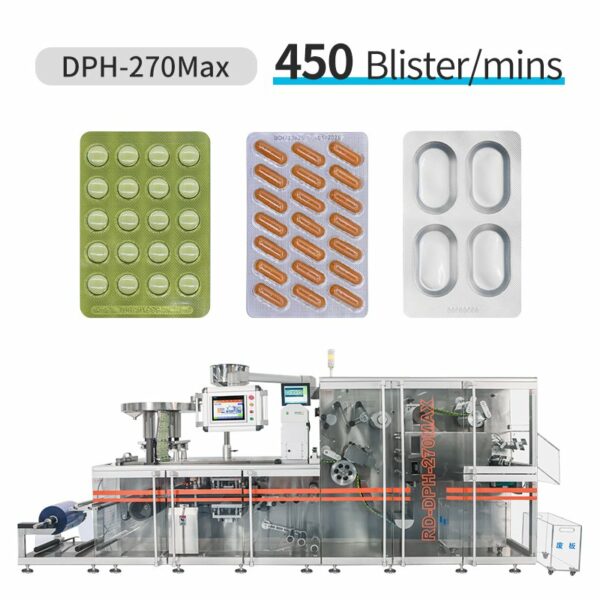

Máquina de embalagem blister de alta velocidade

Máquina de embalagem blister de alta velocidade é um equipamento especializado utilizado para embalar produtos como comprimidos, cápsulas, ampolas ou outras formas sólidas em blisters. Essas máquinas são amplamente utilizadas nas indústrias farmacêutica, nutracêutica, alimentícia e cosmética devido à sua capacidade de embalar produtos de forma eficiente, em um formato selado e protegido.

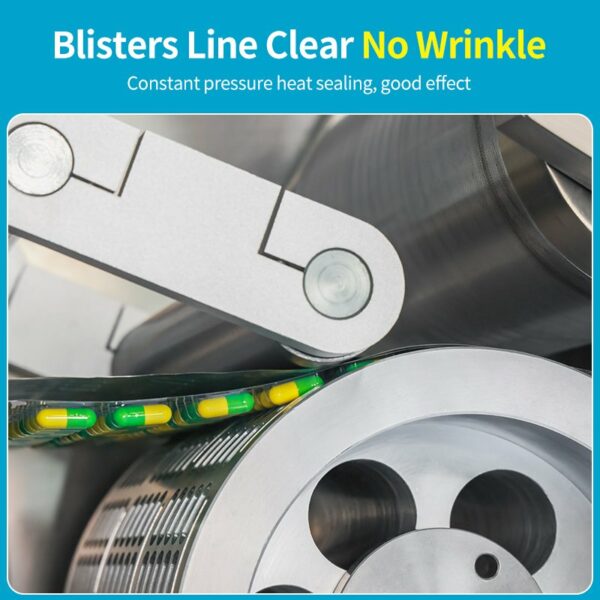

As embalagens blister proporcionam uma solução de embalagem ideal, oferecendo visibilidade do produto, protegendo-o da umidade, luz e contaminação, além de garantir a dosagem precisa em cada embalagem. A máquina de embalagem blister de alta velocidade se destaca em ambientes de produção em massa, oferecendo processamento rápido com mínima intervenção humana. Ela integra os processos de conformação, selagem, alimentação e corte em um ciclo contínuo, garantindo uma operação simplificada e eficiente.

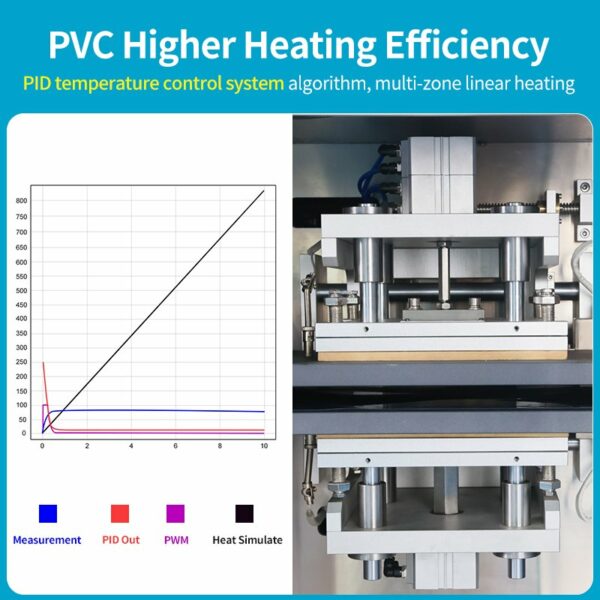

Essas máquinas são equipadas com tecnologias avançadas, como sistemas de alimentação automatizados, mecanismos de conformação e selagem de precisão e controles programáveis, todos visando alcançar alta produtividade e manter rigorosos padrões de qualidade. Com versatilidade para lidar com diversos materiais e designs de blister, as máquinas de embalagem blister de alta velocidade desempenham um papel fundamental para garantir a embalagem eficiente e segura dos produtos.

Especificação:

Até 27.000 bolhas/minutos

Aplicável para comprimidos, cápsulas e medicamentos, etc.

Entrega rápida em 15 dias