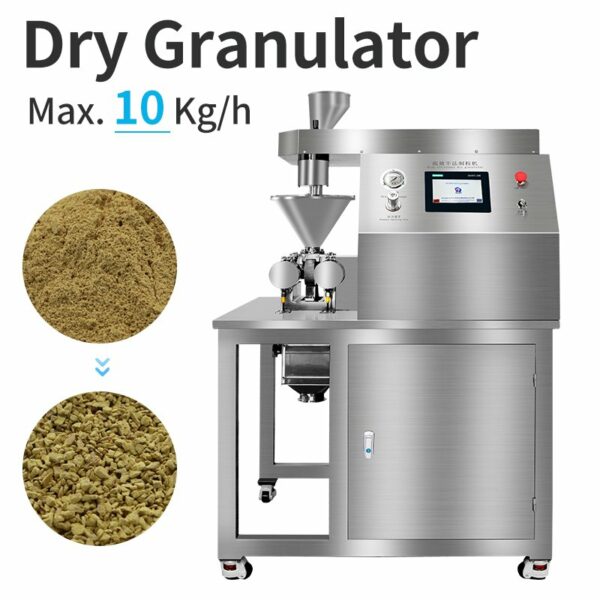

Granulador Seco

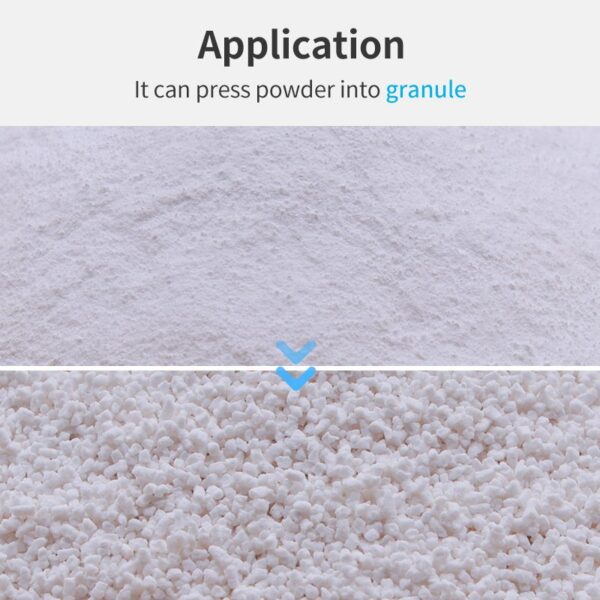

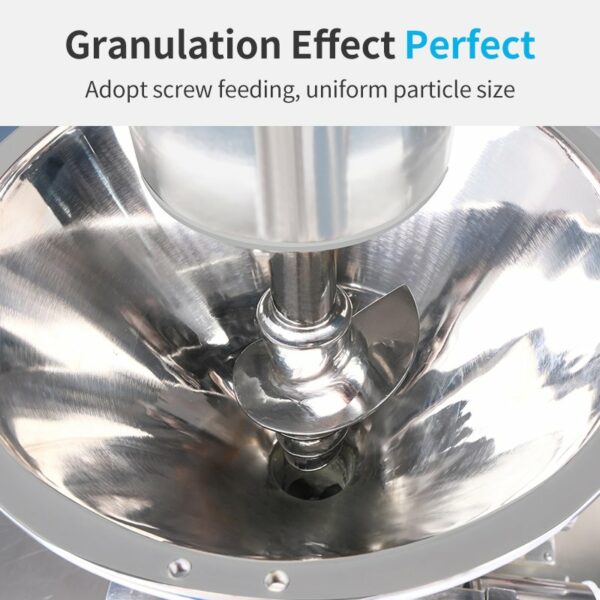

Dry granulator is carried out by compacting powder under high pressure to form dense sheets, which are then broken down into granules. This process is especially useful for moisture-sensitive materials or those that degrade in the presence of liquid or heat.

Pharmaceutical Industry: Dry granulation is often used for materials that are sensitive to heat or moisture, such as active pharmaceutical ingredients (APIs) that might degrade during wet granulation. It is ideal for the production of granules that are later compressed into tablets.

Chemical Industry: Used for producing granules from chemicals that are heat- or moisture-sensitive, such as those used in fertilizers or detergents.

Food Industry: Dry granulators are used to form granules from food powders, such as seasoning or flavor enhancers, where the addition of moisture is undesirable.

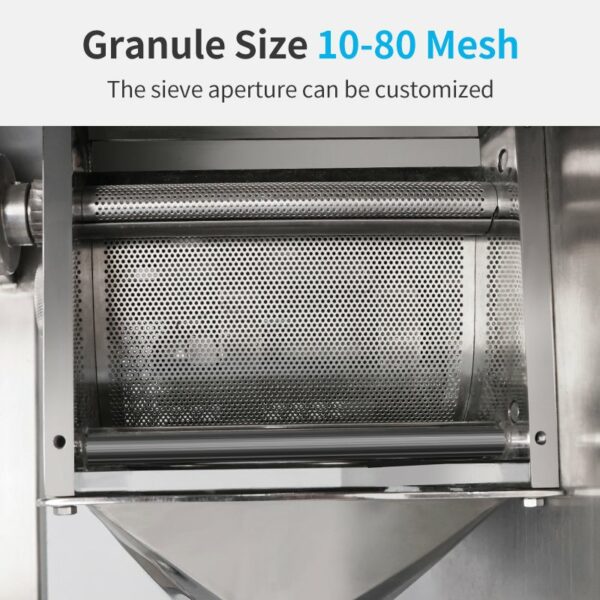

By converting fine powders into granules, dry granulators improve product handling, flowability, and compressibility for downstream processing like tableting or encapsulation.

Especificação:

Up to 10 kg/h

Delivery within 7 days

Suit for moisture-sensitive materials