Máquina de embalagem de blisters líquidos DPP-100L

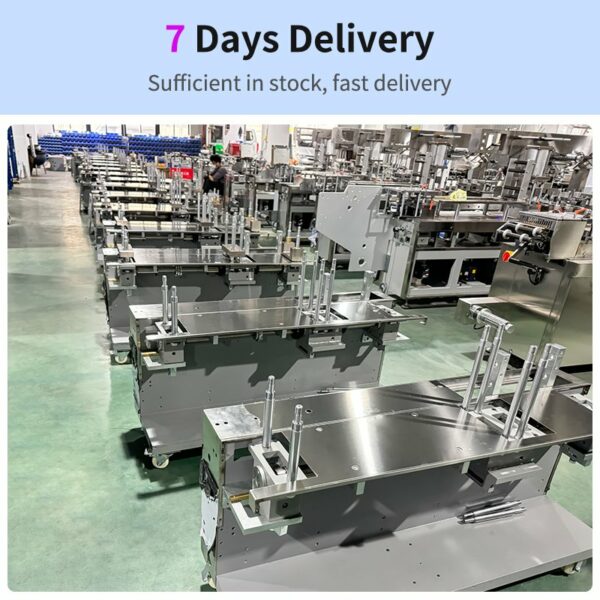

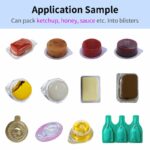

DPP-100L liquid blister packing machine wIth the functions of fully automatic forming, feeding, sealing, punching and batch number coding, It can automatically seal perfume, jam, honey into blisters.

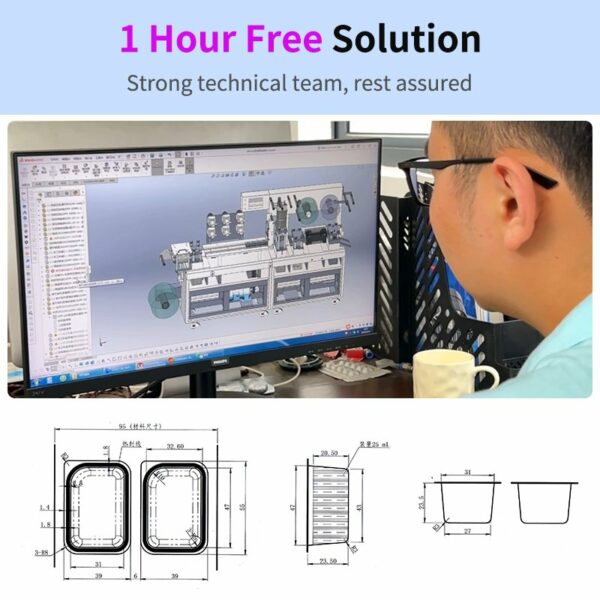

Forming the Blisters: The film is heated and then molded into the desired shape using either a vacuum or compressed air to create cavities that will hold the liquid.

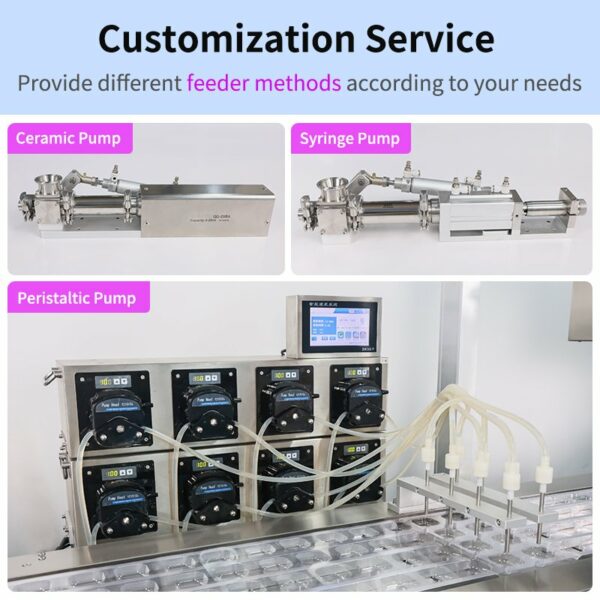

Filling the Blisters: After the blister cavities are formed, the machine accurately fills each cavity with a predetermined amount of liquid. This filling is done through a dosing system, ensuring consistent volume in each blister.

Sealing the Blisters: Once the liquid is filled, the machine seals the blisters with a sealing material, often aluminum foil. The sealing process is done using heat and pressure, ensuring that the blister is airtight and prevents leakage.

Cutting and Ejecting: After sealing, the blisters are cut into individual units or strips. Máquina de embalagem blister may also print batch numbers, expiration dates, or other details on the sealed side. Finally, the finished blisters are ejected from the machine, ready for packaging.

Especificação:

Up to 2,300 Blisters/h

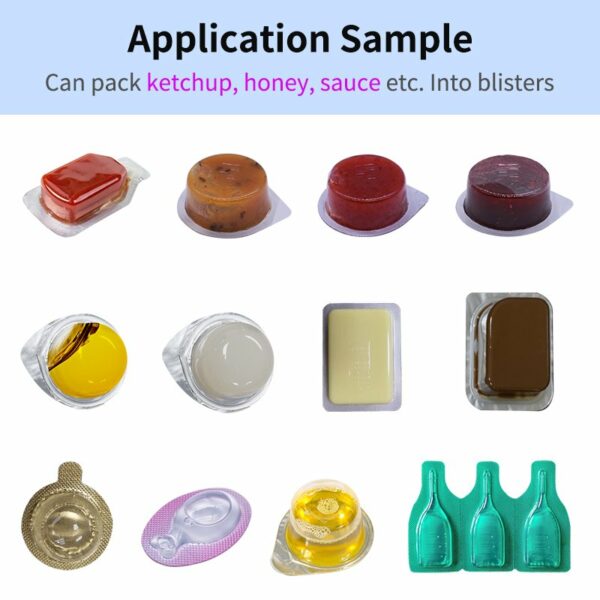

Applicable for sauce, jam, ketchup…