ZP-17D Rotary Tablet Press Machine

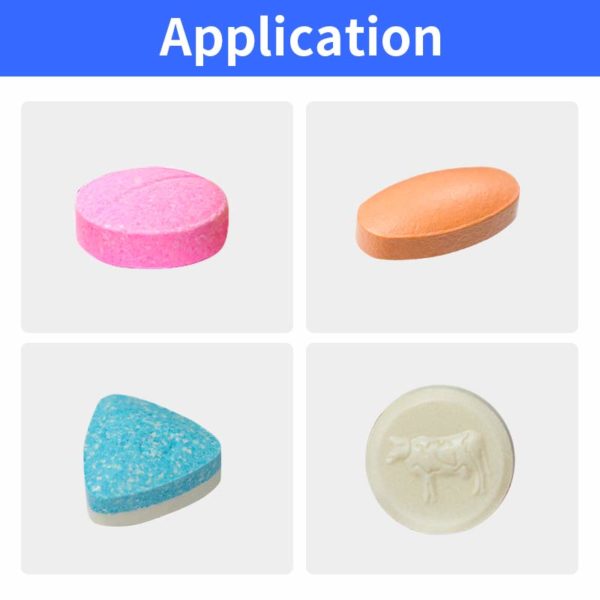

Also called as multi-station tablet press, can efficiently press powder and granules into tablets with diverse diameters and thicknesses. And with customized dies, the ingredients can even be pressed into different shapes for your needs, such as round, triangle, core rod, and special-shaped tablets.

Especificação:

Até 37.800 peças/h

Max. dia. of tablet 20mm

Pressão máx. 100 kN

Entrega rápida em 15 dias