1. Join Us at Shenzhen CPHI & PMEC – Booth 8A57, Hall 8

We are excited to announce that Ruidapacking, a leading manufacturer of pharmaceutical and packaging machinery, will participate in the CPHI & PMEC exhibition in Shenzhen from September 1 to 3, 2025. Our booth (8A57, Hall 8) will feature live demonstrations of our latest equipment, including the newly launched large tablet press designed for producing extra-large tablets such as salt blocks, bath bombs, and detergent tablets. This marks our third exhibition this year, following successful appearances at the Algeria Expo in April and CPHI Shanghai in June. We invite all industry professionals, partners, and clients to visit our booth to explore innovative solutions and exchange insights on advancing production efficiency.

2. Introducing the Large Tablet Press: Solving Production Challenges

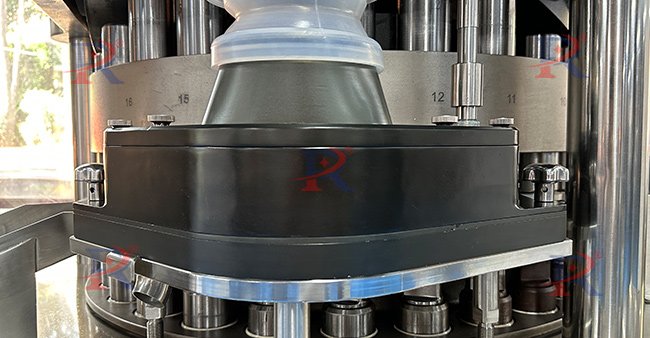

At the Shenzhen exhibition, we will proudly unveil our groundbreaking large tablet press, engineered to address the growing demand for large-diameter tablets like salt blocks, bath balls, and detergent discs. Traditional tablet presses often struggle with insufficient hardness and low output when producing these items, leading to fragile tablets and high waste of . Our new machine tackles these issues with the following innovations:

High-Pressure Capability: Equipped with 400kN main compression and 150kN pre-compression, our press ensures tablets achieve optimal hardness without breaking at the discharge point. This is critical for large tablets, which require intense pressure to maintain structural integrity.

Specialized Discharge System: Salt blocks remain fragile for the first 60 seconds after compression. To prevent damage, our machine features a gentle discharge outlet connected to a flat conveyor belt, allowing tablets to stabilize before proceeding to packaging. This minimizes breakage and maximizes output.

Intelligent Feeding System: Our forced feeder, inspired by Fette technology, ensures precise feeding and quantitative material recycling. By controlling material input accurately, we reduce raw material waste and lower production costs, especially important for large-tablet production where overfeeding is common.

Easy Maintenance and Flexibility: Unlike conventional tablet presses, our machine allows quick molds changes without replacing the entire tooling set. The molds splits into upper and lower sections, with standardized punch bodies and interchangeable punch heads. This enables rapid switching between tablet shapes or sizes, reducing downtime and enhancing operational flexibility.

To complement the tablet press, we also provide end-to-end packaging solutions, including pillow packaging machines for initial wrapping, bagging machines for máquina de embalagem de sacos pré-fabricados, and cartoning machines for boxed products. This integrated approach ensures a seamless production line from compression to final packaging.

3. Expanding Global Presence: See Us at Russia’s Exhibition in Novembe

Our commitment to global engagement continues with plans to exhibit at the Russia CPHI in November 2025. If you are attending the event, we warmly welcome you to visit our booth for live demonstrations and technical discussions. As a manufacturer dedicated to innovation and customer-driven solutions, we look forward to sharing insights and building partnerships worldwide.