캡슐 필러 장비

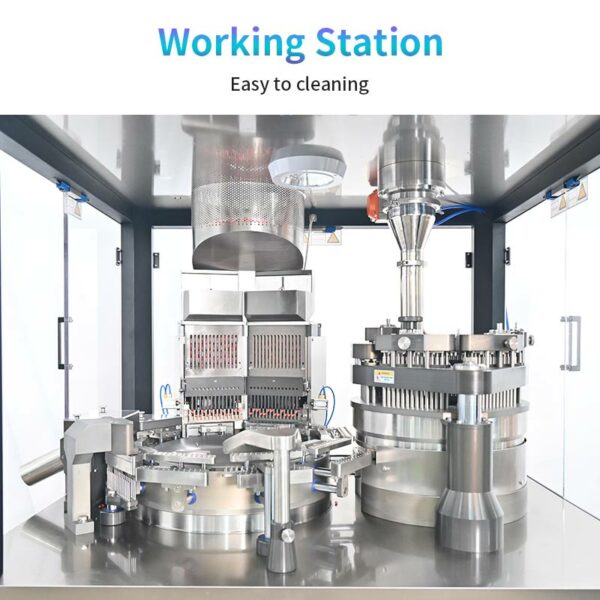

Capsule filler equipment working principle involves several stages, which ensure that empty capsules are filled with a precise amount of powder, granules, or other forms of medication or supplement.

Capsule Orientation: The machine separates the capsule cap and body, positioning them in holders so they can be filled with the desired material.

Dosing and Measuring: Powder or granular material is prepared and measured to ensure consistent filling.

Rejoining Cap and Body: After filling, the capsule cap is repositioned over the body. A locking mechanism then securely joins the two halves of the capsule.

Capsule Ejection: The filled capsules are ejected from the machine into a collection area or conveyor for further packaging or inspection.

전반적으로, 캡슐 충전기 offer high speed and precision, ensuring each capsule is filled uniformly, which is critical in pharmaceutical and nutraceutical manufacturing.

사양:

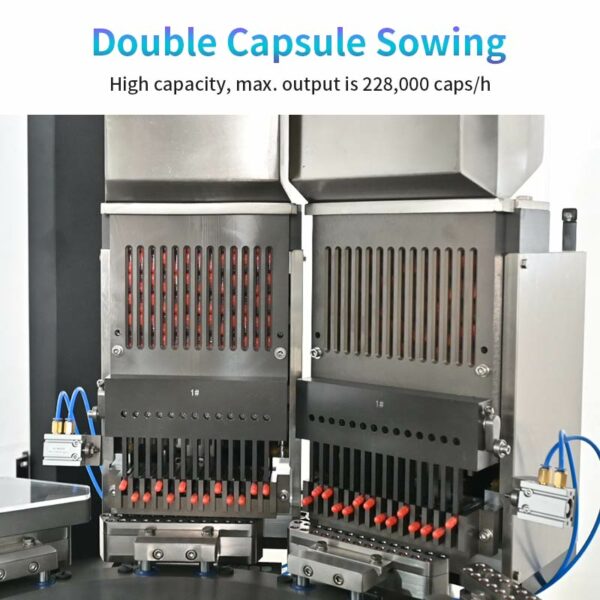

최대 228,000 캡/시간

#000 ~ 5캡슐에 적용 가능