連続自動カートン包装機

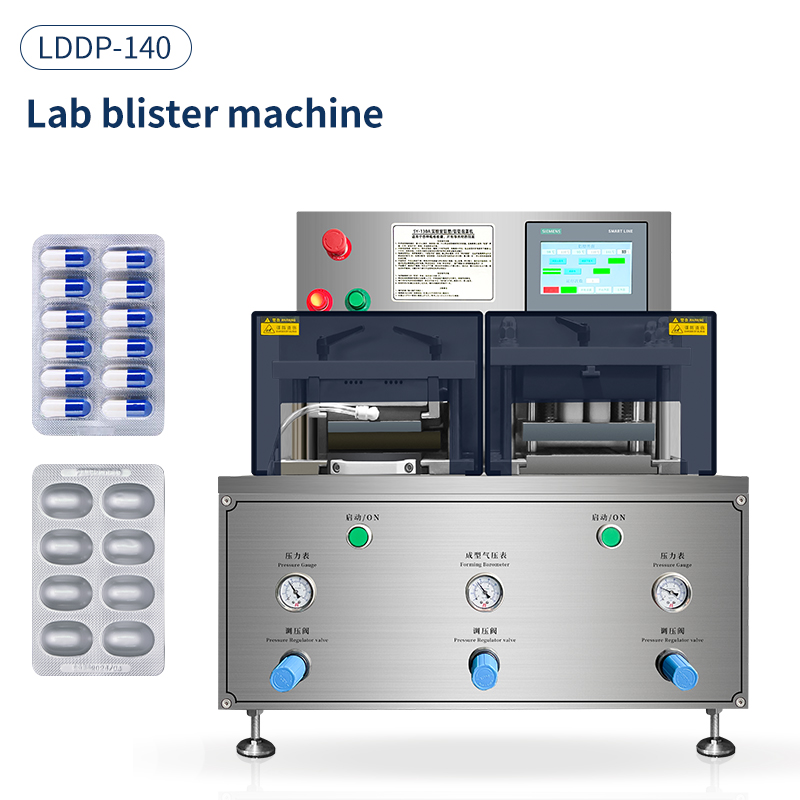

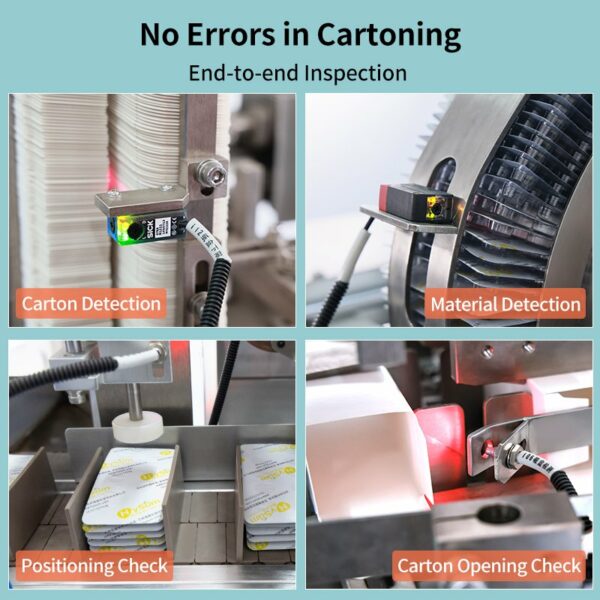

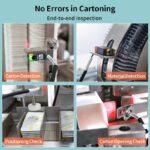

Continuous automatic cartoning machine can pack blister plates, tubes, pouch, strips and other into cartons. Designed for products that are inserted horizontally into the carton. Cartoners can connected pillow packing machine and blister packing machine into production line, with sensors and PLC (Programmable Logic Controller) systems ensuring precise operation and minimal human intervention.

Auto cartoning packing machine can be adjusted to handle different carton sizes and types of products, offering versatility in packaging operations. These machines significantly increase packaging speed and efficiency compared to manual packing, making them essential in high-volume production environments. Cartoning machines are widely used across various industries including: pharmaceuticals, food and beverage, cosmetics…

要約すれば、 blisters cartoning machine automates the process of carton open, filling, and sealing, thereby enhancing productivity and ensuring consistent packaging quality.

仕様:

最大120カートン/分

ビスタープレート、ボトル、サシェなどに適用可能

20日間の迅速な配送