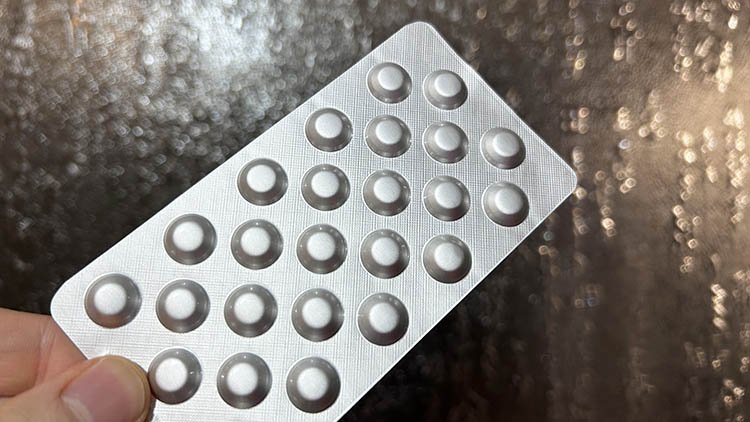

Blister packs act as protective shells for items such as pills, tablets, and capsules. Its transparent, sealed design offers a clear view of contents and helps prolong product shelf life. Blister pack packaging is widely used for packing pharmaceuticals, food, and electronics, where it boosts safety and improves product presentation.

What are traditional and trending types of blister packaging? How are blister plates made? This article will answer these questions and further reveal high-performance solutions for producing pharmaceutical blister packs.

1. What Is a Blister Pack?

First of all, a blister pack (also called as “blister sheet” or “blister plate”) is a package typically made from plastic and aluminum foil, featuring individual plastic blister cavities for products such as tablets, pills and capsules, sealed with an aluminum foil lidding.

Medicine blister packs are usually produced by operating an automatic ブリスター包装機. In the blister packing method, blister cavities are shaped to contain products and are then sealed with a cover often made from aluminum foil. Blister pack packaging solution is essential for protecting a wide array of items, providing goods with tamper-evident seals, and barriers against moisture, contaminants, oxidization, and physical scratches.

2. 何ですか Common 材料 for Blister Packs?

Materials selected for producing blister sheets are determined by industry requirements and the specific type of blister packaging needed. Content below is about 4 of the most common materials:

● PVC

● PET

● Aluminum foil

● PDVC coating

2.1 PVC(ポリ塩化ビニル)

PVC is a popular kind of plastic for making blister cavities of pharmaceutical blister packs because of its excellent transparency and reliable protection. It delivers a plastic shell against contaminants and moisture for medication tablets, capsules, and consumer goods. PVC is also a low-cost option, ideal for high-volume capsule tablet manufacturing.

2.2 PET (Polyethylene Terephthalate)

More expensive than PVC, PET is a recyclable polymer growing in popularity as a sustainable choice for forming plastic blister cavities of medicine blister packs. Its protective barrier to moisture and oxydization is more robust than PVC, and its environmental friendliness is a significant advantage, since it enjoys recyclability. PET also provides outstanding clarity, ideal for retail scenarios where product visibility is important for consumer engagement.

2.3 Aluminum Foil

Aluminum foil lidding is employed in blister pack packaging to provide an optimal barrier for products requiring high-level protection, including drug tablets and softgels. This material ensures a secure seal impermeable to moisture, air, and light—crucial for maintaining the stability and integrity of vulnerable solid-dose forms such as pills and capsules.

2.4 PVDC Coating

Both PVC or PET materials do not provide sufficient resistance to moisture and oxygen. To address this case, PVDC coating exists as a barrier layer applied to plastic blister materials. It improves resistance to moisture, oxygen, and light, and helps extend shelf life of drug tablets and gelatin capsules, protecting sensitive medication from degradation.

According to the 4 common kinds of blister pack materials mentioned above, we hereby have a comparison of their characteristics based on various dimensions:

| Property | PVC | ペット | アルミホイル | PVDC Coating |

| Rigidity & Strength | ★★☆☆☆ | ★★★★☆ | — (Used as lidding) | — (Coating, not a base) |

| 防湿バリア | ★★☆☆☆ | ★★★☆☆ | ★★★★★ | ★★★★★ |

| 酸素バリア | ★☆☆☆☆ | ★★☆☆☆ | ★★★★★ | ★★★★★ |

| Clarity for Visibility | ★★★★★ | ★★★★★ | ★☆☆☆☆ | ★★★★☆ |

| Formability | ★★★★★ | ★★★★☆ | — (Lidding only) | — (Applied coating) |

| Cost Efficiency | ★★★★★ | ★★★☆☆ | ★★☆☆☆ | ★★☆☆☆ |

| Environmental Friendliness | ★☆☆☆☆ | ★★★☆☆ | ★★☆☆☆ | ★☆☆☆☆ |

3. What Are Traditional Blister Pack Packaging Types?

As we know, plastic (PVC/ PET) and aluminum foil are usually applied in making blister cavities and blister sheet liddings. However, can blister cavities be made from aluminum foil? Can a blister pack be produced by utilizing one single kind of material? Let’s know 4 common blister pack packaging types:

● Plastic-Alu blister sheets

● Alu-Alu blister sheets

● Paper-plastic blister sheets

● Blister card

3.1 Plastic-Aluminum Blister Packs

As a hybrid blister packaging way, plastic-aluminum blisterpaks contain clear, transparent plastic blister cavities that hold drug tablets or gel capsules, and backings made from aluminum foil. These blister plates create protective compartments, commonly used for packing pharmaceuticals, food, and small consumer goods, and they offer excellent product visibility and airtight barriers.

3.2 Aluminum-Aluminum Blister Packs

They are pharmaceutical packaging consisting of two solid aluminum foil layers sealed together, forming individual aluminum blister cavities for protecting medicine. Compared to aluminum-plastic capsule blister packs, their key advantage is better protection. The all-metal material provides an exceptional, nearly impenetrable barrier against moisture, oxygen, and light, ensuring maximum product stability and extending shelf life of medication tablets, ideal for sensitive drugs like biologics or hygroscopic medications.

3.3 Paper-Plastic Blister Packs

Another hybrid packaging way as well. A paper-plastic blister sheet combines a paperboard backing with transparent plastic cavities. Primarily used for containing electronic products and sometimes for packaging pills and capsules, these packs are more eco-friendly than aluminum-plastic blister plates due to their easier recyclability, but this friendliness comes at the cost of weaker moisture and oxygen barriers, less suitable for sensitive pharmaceutical tablets and capsules, because paper cannot resist moisture and even absorb ambient moisture.

3.4 Blister Cards

A blister card is a packaging format where a formed plastic-aluminum pharmaceutical blister pack is sealed between two layers of paper card, securely clamping the pack. Commonly used for packing medication and small consumer goods, blister card packaging provides better product presentation and resistance to collision and scratches, though it consumes more package material and is slightly more expensive to produce.

| 特徴 | Alu-Plastic Blister Packs | Alu-Alu Blister Packs | Paper-Plastic Blister Packs | Blister Cards |

| Oxygen & Light Resistance | ★★★☆☆ | ★★★★★ | ★★☆☆☆ | ★★★★☆ |

| Moisture Resistance | ★★★☆☆ | ★★★★★ | ★☆☆☆☆ | ★★★★☆ |

| Anti-Collision / Protection | ★★★☆☆ | ★★★★☆ | ★★★☆☆ | ★★★★☆ |

| Product Visibility | ★★★★★ | ★☆☆☆☆ | ★★★★★ | ★★★★★ |

| Product Presentation | ★★★☆☆ | ★★☆☆☆ | ★★★☆☆ | ★★★★★ |

| Expense (Cost) | ★★★☆☆ | ★★★★★ (highest) | ★★☆☆☆ | ★★★★☆ |

| Environmental Friendliness | ★★☆☆☆ | ★★☆☆☆ | ★★★☆☆ | ★☆☆☆☆ |

Besides the 4 traditional drug blister packaging methods above, there are some trending types of pharmaceutical blister packaging, and we will dive into these types gaining increasingly more popularity.

4. What Are Trending Blister Pack Packaging タイプs?

Beyond traditional aluminum-plastic and alu alu blister pack formats, the industry is embracing innovative blister packing solutions. Trends include the adoption of recyclable mono-materials, the integration of smart features like embedded sensors for medical instruction adherence tracking, and user-friendly designs that balance child-resistance with easy access for the elderly, heralding a new era for pharma packing.

The blister packaging sector is undergoing a transformation, driven primarily by 3 demands:

● Sustainability

● Medication safety and ease of use

● Digital healthcare

4.1 Blister Packing for Upholding Sustainability

Aiming to reduce impact on the environment, the demand for sustainability is pushing the development of mono-material, bio-based, and easily recyclable medicine blister sheets.

A) Recyclable Mono-material Blister Packs

Traditional medical blister packaging consists of composite materials such as plastic PVC and aluminum foil difficult to separate and recycle.

In contrast, recyclable mono-material pharmaceutical blister sheets use the single plastic material for both the blister layer and the lidding layer. This blister packing way allows the packaging to enter the corresponding plastic recycling stream without the need of separation, enhancing blister package recyclability. Simplifying the recycling process, the uniform material requires no separation and can be directly crushed, cleaned, and reprocessed, reducing recycling costs.

B) Renewable Bio-based Material Blister Packs

Traditionally, the plastic package material is sourced from fossil fuel. Nowadays, a trend in blister packing is the shift towards blister sheets made from renewable, bio-based materials. The accomplishment of this shift involves two ways:

Replacing conventional, fossil-fuel plastics, the industry utilizes alternatives, such as bio-based PP or PE derived from sugarcanes, and cellulose-based plastic film sourced from wood pulp or cotton. These materials possess an identical chemical structure to their petroleum counterparts, ensuring performance and recyclability.

4.2 Blister Packing Facilitating User Safety and Convenience

To enhance medication safety and ease of use, trending pharmaceutical blister plates feature dual optimizations: child-resistant designs to prevent accidental ingestion, and senior-friendly features for improved accessibility.

This innovative packaging designed for dual purposes is often achieved through a “peel-push” mechanism. Instead of just pushing tablets through, users must first peel away a thin, sealed aluminum foil lidding. This two-step action is complex for a child to execute, yet it requires minimal force manageable for seniors. These drug blister packs may also feature large, clear labeling and contrasting colors for better visibility, ensuring independent medication access.

4.3 Intelligent Blister Packaging Facilitating Digital Healthcare

Digitally connected pharmaceutical blister packaging merges physical medication with digital health tools. This is achieved by printing unique QR codes on each blister cell for patient education (guidance words or videos), or is achieved by integrating ultra-thin, printed sensors.

In the latter case, when a pill or capsule is pushed out, the sensor circuit breaks, recording an event. Then this data is transmitted via Bluetooth to an app, which sends dosage reminders and generate compliance reports for healthcare providers. This intelligent medication blister packaging effectively enhances patients’ medication adherence for chronic disease management and clinical trials, supporting remote patient monitoring.

Despite emerging blister packaging trends above, traditional aluminum-plastic and aluminum-aluminum blister plates remain the standard for most pharmaceutical applications, continuing to dominate the market due to their proven reliability.

5. How Are Traditional Blister Packs Produced via Blister Packaging Machine?

As traditional blister plates remain the mainstream in the pharmaceutical packing sector, we pay attention to the way that they are made.

Modern pharmaceutical blister packaging is efficiently achieved by using automatic blister packing machines. These machines enable large-scale pharma packing by rapidly and precisely placing capsules, tablets, or syringes into plastic blisters.

The production process is straightforward: the tablet blister packing machine accurately positions tablets into blister cavities and then securely seals blisters with an aluminum foil lidding, including stages below:

●Blister 熱成形: A roll of plastic film, such as PVC or PET, is first fed into a pill blister packing machine and heated until pliable. The film is then drawn into a thermoforming mold, and as the mold elevates and compresses the plastic film, a web of uniform blister cavities is then shaped to contain specific products.

●Blister 充填: Formed blisters next move into a filling station. Here, individual blister cavities are precisely filled with drug tablets or gelatin capsules. This stage is done by using automated product feeding devices such as guide rails or high-speed rotational brushers.

●ヒートシール: The lidding material, typically a roll of aluminum foil coated with a heat-sealable polymer, is placed over filled blisters. At this station of a pack blister machine, via intermittent upward and downward motions of a heating plate, heat and pressure are applied to melt the polymer coating on aluminum foil, bonding it securely to flanges of plastic blisters, creating a hermetic seal.

●切断: Sealed blister web then continuously passes through a cutting station that trims and cuts the web into individual, finished blister packs.

6. How to Produce Blister Sheets で 高い Speed?

The answer is directly laid: Use a high speed blister packing machine (roller-type).

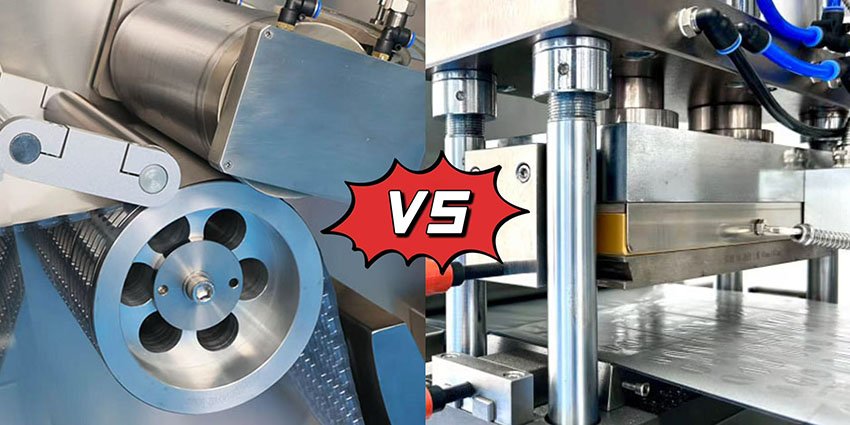

Contemporarily, a majority of automatic blister packaging machinery that carry out blistering stages above are flat plate models with a production capacity ranging from 40 to 200 packs per minute. In other words, a flat-plate auto blister packer exists as a medium or low speed model.

In comparison, high-speed blister pack packaging with a max output of 500 blisterpaks per minute is typically carried out by using a roller type blister pack packaging machine. Generally speaking, processing stations and the working theory of roller-type and flatbed-type blister machines are almost the same.

Of notable difference from a low-speed blistering machine in pharmaceutical industry, a high speed blister packing machine employs a continuous traction system instead of an intermittent one. This uninterrupted material advance method ensures more precise blister sealing, and it enables obviously higher speeds for both blister forming and heat sealing process. Top-tiered pharmaceutical packaging equipment manufacturers such as Romaco and ルイダパッキング are capable of stably supplying high speed blister packaging machines. Take DPH 270Max automatic blister machine for an example. This high-speed roller-type model enjoy advanced features:

●Full-Servo Technology: Six stations including blister forming, forming traction, heat sealing, cutting, and cutting traction are all driven by servo motors, enabling precise control over PVC/Alu material feeding speed, sealing pressure, and temperature.

●Intelligent Tracking: Equipped with a motion controller that autonomously tracks the operating speed of each station. For example, if the forming station slows down, subsequent heat sealing and cutting stations automatically reduce speed accordingly.

●Roller-Type Heat Sealing: The blister machine utilizes a roller sealing structure, tremendously increasing blister sealing speed and supporting cutting rates of up to 200 cycles/minute, enhancing overall packaging efficiency.

●High-Precision Rejection: Standard with German Basler high-definition industrial cameras to reject defective blister sheets. This automatic waste rejection occurs if issues like missing tablets, fragmented capsules, overlapping tablets, size variations, or color differences are detected.

It is worth noting this high-speed blister sealing machine saves over 10% in packaging materials compared to a flatbed pill tablet blister packing machine, making it a prefered choice for mass capsule blister pack production.

結びの言葉

The evolution of blister packaging is marked by a decisive shift towards sustainable materials, user-centric designs, and intelligent digital healthcare integration. These innovative trends of blister packs, supported by advanced high speed tablet blister packing machines, are shaping the future of pharmaceutical blister pack packaging to meet modern medical and healthcare demands.