Astucciatrice a caricamento laterale

La confezionatrice a caricamento laterale è un'apparecchiatura essenziale utilizzata nei processi di confezionamento, progettata per formare, riempire e sigillare automaticamente scatole per una varietà di prodotti, tra cui prodotti farmaceutici, alimentari, cosmetici e beni di consumo. Può anche collegare la linea di macchina confezionatrice blister e macchina imballatrice per cuscini.

Le astucciatrici possono gestire scatole di vari formati e stili, inclusi astucci pieghevoli, scatole espositive e scatole di forme speciali. In genere operano con un movimento continuo o intermittente, consentendo una produzione ad alta velocità mantenendo la precisione nel posizionamento e nella sigillatura del prodotto.

Il processo generalmente prevede l'inserimento di cartoni piatti nella macchina, dove vengono formati in una forma tridimensionale, riempiti con i prodotti e quindi sigillati, spesso con colla o con una chiusura a lembo. I modelli più avanzati sono dotati di sistemi integrati per il controllo qualità, che garantiscono un riempimento corretto e una sigillatura sicura per prevenire manomissioni o contaminazioni del prodotto.

Grazie alla capacità di soddisfare diverse esigenze di confezionamento, le macchine incartonatrici sono essenziali per le aziende che desiderano ottimizzare le proprie operazioni di confezionamento, mantenendo al contempo l'integrità del prodotto e la conformità agli standard del settore.

Specifica:

Fino a 120 cartoni/min

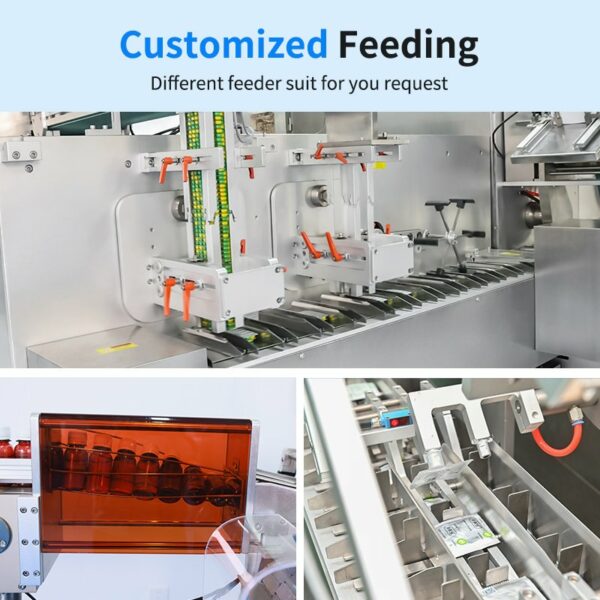

Applicabile per piatti da portata, bottiglie, bustine ecc.

Consegna rapida in 15 giorni