In imballaggio farmaceutico, the right feeder plays a crucial role in maintaining an efficient and reliable production line. Different products and packaging setups require specific types of feeders to ensure smooth operation, accurate dosing, and minimal damage to delicate items like tablets and capsules. Understanding the functions and applications of each feeder can help you choose the best option for your production line. Below, we’ll explore six commonly used feeders in pharmaceutical packaging and detail how they meet different operational needs.

1. Disk Vibrating Feeder

The disk vibrating feeder is designed to provide a steady and controlled flow of products, using vibrations to transport tablets or capsules efficiently. This feeder’s primary benefit is the precision it brings to the packaging process, as it ensures an even flow that prevents bottlenecks or clumping.

Come funziona

The disk vibrating feeder operates by placing products on a vibrating disk, which gently propels them forward. This controlled motion is particularly important for fragile items that may break under excessive force. By minimizing impact, this feeder type reduces the likelihood of product damage while maintaining a smooth supply chain.

Ideal Use Cases

The disk vibrating feeder is especially suited for compact production lines where space is limited. Its efficiency in managing delicate products, such as coated tablets, makes it a popular choice for manufacturers focused on preserving product integrity.

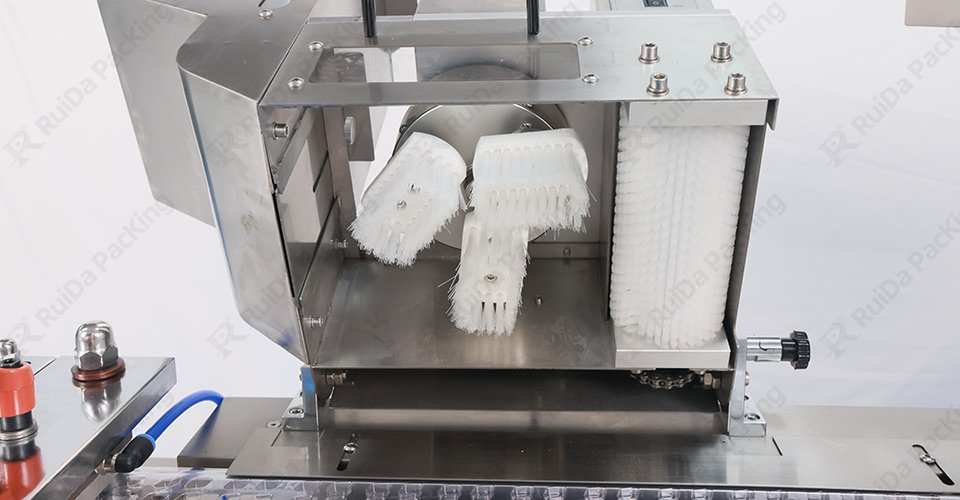

2. Disc Brush Feeder

The disc brush feeder is known for its gentle handling of products, making it an excellent choice for items that need precise alignment. Equipped with brushes that guide items along a rotating disc, this feeder separates and organizes products, ensuring they are positioned accurately for further processing.

Come funziona

The disc brush feeder utilizes brushes that rotate with the disc, gently guiding tablets or capsules. This system reduces the risk of blockages, helping to avoid production interruptions. The brushes also serve to separate products, preventing overlapping or misalignment as they move toward the packaging phase.

Ideal Use Cases

This feeder type is ideal for handling smaller, delicate items like capsules or uncoated tablets that require careful management. By minimizing friction and maintaining product spacing, the disc brush feeder can effectively reduce damage while optimizing accuracy.

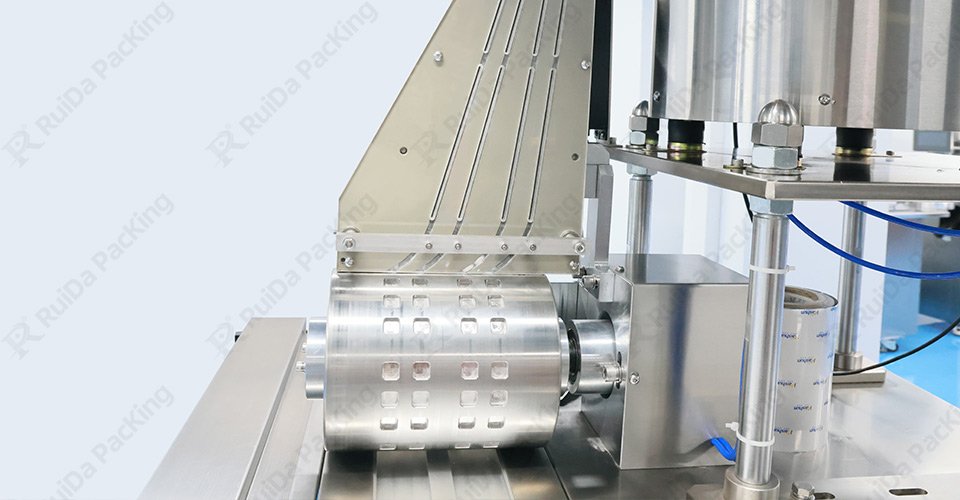

3. Inclined Plate Roller Brush Feeder

The inclined plate roller brush feeder combines an inclined plane with roller brushes, providing a controlled flow that maintains alignment and prevents clogging. This unique design helps move products at an angle, which is beneficial for lines requiring gravity-assisted flow.

Come funziona

This feeder’s inclined design allows tablets or capsules to move downward at a steady rate, aided by rollers and brushes that guide them. The roller brushes ensure that products maintain their orientation and spacing, creating a consistent flow that is crucial for high-speed packaging lines.

Ideal Use Cases

If you need a feeder that ensures precise alignment and minimizes blockages, the inclined plate roller brush feeder is an excellent choice. This type is particularly useful in pharmaceutical applications where maintaining orientation is essential, such as with oval or capsule-shaped products.

4. Roller Brush Feeder

The roller brush feeder is designed to handle high-speed operations, making it an optimal choice for packaging lines that demand fast and continuous product flow. It operates with a series of rotating brushes that move products forward while ensuring even spacing and alignment.

Come funziona

Rollers with brushes gently separate products and maintain a consistent flow rate, preventing items from clumping together. This action helps in avoiding production stoppages, as the roller brush feeder’s design keeps items moving at a steady pace without unnecessary friction or impact.

Ideal Use Cases

This feeder type is beneficial for handling products prone to damage, such as soft tablets or capsules. It’s also well-suited for high-speed lines that require rapid and uniform product spacing. The roller brush feeder’s efficiency in maintaining flow without breakage is a major advantage in pharmaceutical packaging.

5. Disc Brush Roller Feeder

The disc brush roller feeder is a hybrid option that combines the advantages of a rotating disc and roller brushes, providing a flexible solution for various products. Its design makes it a versatile choice for packaging lines that require a balance of speed and precision.

Come funziona

Products are moved along a rotating disc, guided by rollers and brushes that keep them spaced and aligned. This hybrid system allows for greater flexibility in handling different types of products, as the combination of disc and roller movement minimizes jamming while ensuring consistent positioning.

Ideal Use Cases

The disc brush roller feeder is ideal for pharmaceutical applications that require flexibility, handling various tablet and capsule shapes. This feeder’s adaptability makes it a great choice if you deal with a range of products on the same packaging line, allowing for smooth transitions between different formats.

6. Capsule-Turning Feeder

The capsule-turning feeder is specifically designed to orient capsules in the correct position before packaging. This ensures that every capsule is positioned consistently, which is essential for precision dosing and sealing in the packaging process.

Come funziona

The capsule-turning feeder flips capsules to a uniform orientation, preparing them for further steps in the packaging line. By handling capsules individually, this feeder minimizes the risk of incorrect orientation, which could lead to dosing inaccuracies or sealing issues.

Ideal Use Cases

For capsule-only packaging lines, the capsule-turning feeder is a critical component. Its ability to handle each capsule individually ensures uniformity, making it essential in applications where orientation is crucial, such as blister packaging. This feeder is particularly valuable in lines that prioritize high accuracy and minimal errors in capsule alignment.

Recommended Product: DPP-270Max Blister Packaging Machine

If you’re looking for a reliable machine that complements the feeders discussed above, the DPP-270Max Blister Packaging Machine is an outstanding choice. Known for its versatility and efficiency, this machine is designed to handle various tablet and capsule shapes with precision.

Why It’s a Great Fit for Your Production Line.

The DPP-270Max combines efficiency, precision, and flexibility, making it a perfect addition to any pharmaceutical packaging line. Whether handling high-speed operations or adapting to different product types, this machine supports seamless integration and high-quality output. Its capabilities align well with the feeders outlined in this article, providing a cohesive solution that optimizes every step of your packaging process.

Conclusione

Selecting the right feeder is essential in maintaining the efficiency and quality of your pharmaceutical packaging line. By understanding the strengths and applications of each type of feeder, you can optimize product flow, reduce damage, and ensure accuracy at every stage. Whether your focus is on gentle handling, precise orientation, or high-speed performance, choosing the right feeder supports consistent, high-quality packaging. And by pairing these feeders with an advanced machine like the DPP-270Max, you’re set to achieve a seamless, reliable, and efficient production line that meets the highest standards of pharmaceutical packaging.