For pharmaceutical and nutraceutical companies aiming to access the lucrative U.S. market, achieving FDA compliance is not just a goal—it’s a mandatory standard of excellence. But what truly makes a tablet or capsule “FDA-compliant”? It goes far beyond a simple final product check. Compliance is an end-to-end commitment, woven into every single step of the manufacturing and packaging process, from raw material to sealed bottle.

Sourcing and Handling Raw Materials

It all begins with the ingredients. FDA compliance requires strict adherence to Current Good Manufacturing Practices (cGMP), which start with rigorous supplier qualification. All raw materials—whether active pharmaceutical ingredients (APIs) or excipients—must be sourced from approved suppliers, accompanied by comprehensive documentation (Certificates of Analysis) verifying their identity, purity, strength, and composition. Each shipment must be quarantined, tested, and verified against strict specifications before being released for production. There is no room for uncertainty at this foundational stage.

The Production Stage

The transformation of these raw materials into finished dosage forms is where precision engineering meets stringent protocol.

The Tablet Press (Compression): In the tablet compression process, powders are blended and fed into a tablet press machine. The machine uses immense pressure to compress the powder into uniform tablets within precisely tooled dies. Compliance here means every tablet must have exact weight, hardness, thickness, and dissolution properties. Modern presses are equipped with automated control systems to continuously monitor these parameters and reject any out-of-spec tablets in real-time, ensuring batch consistency.

Itu Encapsulation Machine: For capsules, the encapsulation machine precisely fills two-piece gelatin or vegetarian shells with a predetermined dose of powder, pellet, or liquid. The machine’s settings must be calibrated to ensure each capsule is filled to the correct weight and that the two halves are perfectly sealed. Any malfunction leading to under-filled, over-filled, or malformed capsules must be detected and rectified immediately.

Ensuring Purity and Safety

After formation, tablets and capsules undergo vital cleaning and inspection stages.

Dedusting and Polishing: Newly pressed tablets are often exposed to excess dust and particles from the compression process. They must pass through a dedusting or screening system to remove this fine particulate, ensuring a clean, professional appearance and preventing cross-contamination. Similarly, capsules exit the encapsulation machine with residual powder and need to be polished in capsule polishers to achieve a brilliant, market-ready finish.

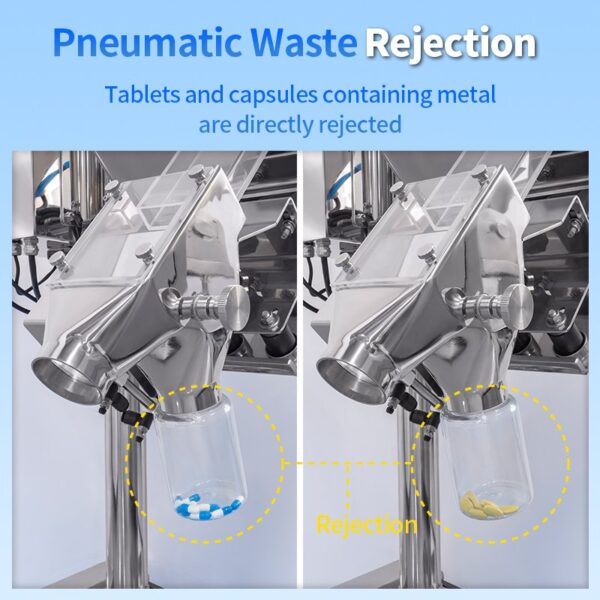

The Non-Negotiable Metal Detection: This is a critical control point. Despite the controlled environment, minute metal particles from wear-and-tear of the manufacturing equipment (like the tablet press punches and dies) could potentially contaminate the product. Therefore, every single tablet and capsule must pass through a highly sensitive pharmaceutical-grade metal detection machine. This detector must be calibrated to reject any product containing ferrous, non-ferrous, or stainless steel contaminants, ensuring 100% metal-free products and protecting consumers from harm.

Final Packaging: The Last Line of Defense

The final step is packaging, which serves to protect the product’s stability and integrity. Packaging must be performed in a controlled environment to prevent contamination. Equipment must accurately count and fill bottles or blister packs. Importantly, the packaging process itself must be validated to ensure it does not introduce any foreign materials. Finally, labels must be accurate and comply with all FDA regulations regarding information, branding, and safety warnings.

Conclusion: Compliance is a Continuous Process

In summary, an FDA-compliant tablet or capsule is the result of a holistic, validated process—not a single action. It is the product of controlled raw materials, precision manufacturing on calibrated equipment like tablet presses and encapsulation machines, meticulous post-production cleaning, rigorous contaminant detection via metal checkers, and secure, accurate packaging. It is this unwavering dedication to quality at every stage that builds the trust and safety demanded by the FDA and, most importantly, by the end consumer.