Automatic Capsule Powder Filling Machine

Automatic capsule powder filling machine offer several advantages that make them an essential choice for pharmaceutical and nutraceutical industries.

High Efficiency and Productivity: Capable of filling a large number of capsules in a short time, increasing overall production capacity. Minimizes downtime with automated operations, ensuring continuous production.

Precision and Accuracy: Ensures accurate dosage of powders, granules, pellets, or liquids, reducing wastage and ensuring uniformity in capsules.

Versatility: Supports a variety of capsule sizes (#000 to 5).

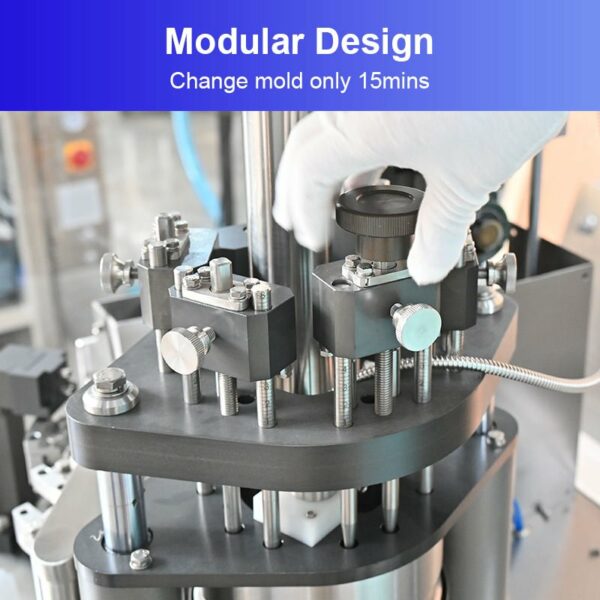

Customizable Features: Machines can be configured with additional options like polishing, sorting, and online rejection systems to meet specific production needs.

Spesifikasi:

Hingga 24.000 pcs/jam

Berlaku untuk ukuran kapsul #000 ~ 5

Cocok untuk bubuk, butiran, pelet