रोटरी टैबलेट बनाने की मशीन

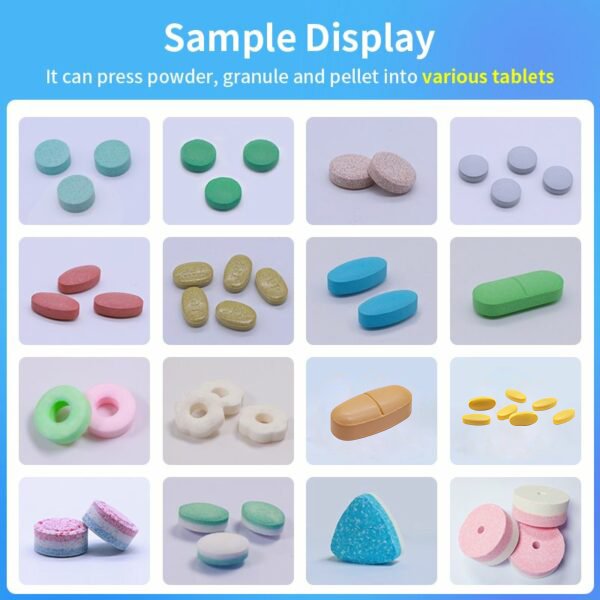

Rotary tablet making machine is a type of tablet press used for producing large quantities of tablets at high speeds. It works by compressing powder or granules into tablets using rotary motion.

Material Loading: Powder or granules are loaded into the feeder system, which can be a hopper or a material storage unit.

Rotary Die System: The machine uses a **rotary die set** that holds the cavities for tablet formation. These dies are mounted on a rotating turret, which allows continuous tablet production.

Compression Stroke: The upper punch and lower punch move toward each other to compress the powder inside the die cavity. The material is compacted under pressure to form a solid tablet.

After compression, the punches move apart, and the compressed tablet is ejected from the die cavity.

विशिष्टता:

160,000 टैब्स/घंटा तक

टैबलेट का अधिकतम व्यास 25 मिमी

अधिकतम दबाव 100kn

15 दिन में त्वरित डिलीवरी