Máquina para fabricar tabletas de hierbas

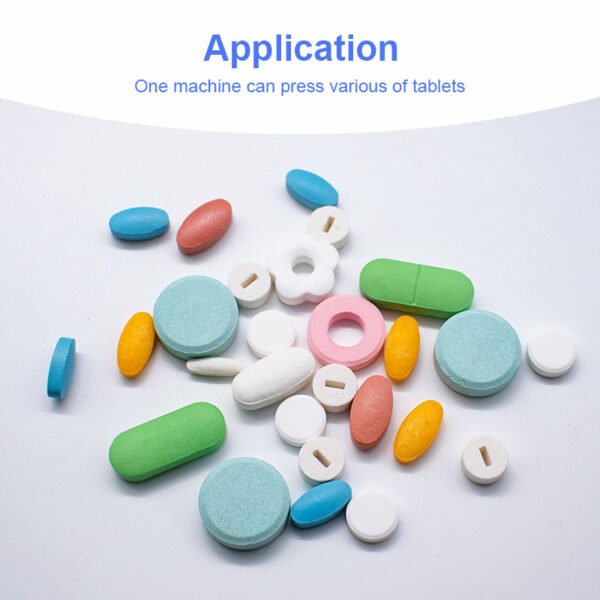

Herb tablet making machine can efficiently press powder and granules into tablets with diverse diameters and thicknesses. And with customized dies, the ingredients can even be pressed into different shapes for your needs, such as round, triangle, core rod, and special-shaped tablets.

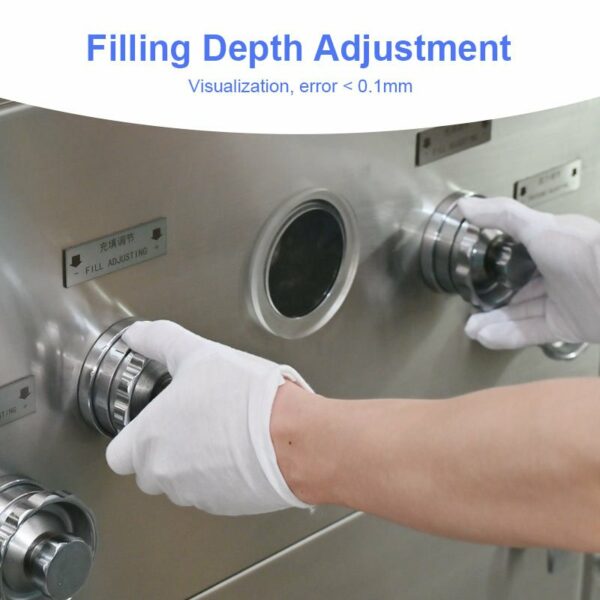

Powder or granulate is loaded into the hopper. The machine features a rotating turret that holds multiple dies and punches. As the die cavity passes under the feeder, it is filled with a pre-measured amount of powder.

The die then moves to the main compression station where the upper and lower punches move towards each other, compressing the powder into a tablet. The force applied can be adjusted to achieve the desired tablet hardness and density.

An ejection mechanism guides the tablet onto a conveyor belt or collection chute for further processing, such as coating or packaging.

Especificación:

Hasta 160.000 pestañas/h

Diámetro máximo de la tableta: 25 mm