Máquina de embalaje blíster DPH-270Max

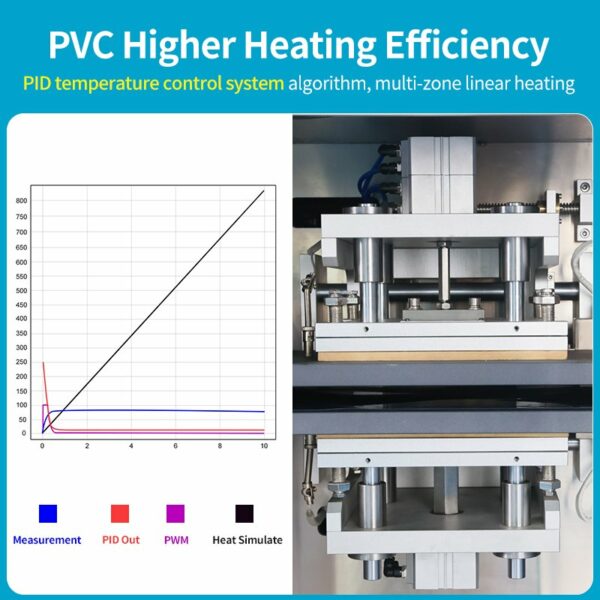

Máquina de embalaje blíster DPH-270Max implica el proceso automatizado de envasado de productos (como comprimidos, cápsulas o geles blandos) en cavidades de blíster preformadas utilizando una película de blíster, normalmente hecha de PVC o PET, y un material de soporte como papel de aluminio.

Formación de la cavidad: La película precalentada se extiende sobre un conjunto de moldes de conformación. Mediante vacío o presión mecánica, se le da forma en bolsas o cavidades individuales que albergarán el producto.

Inspección del producto (opcional): Algunas máquinas tienen un sistema de inspección integrado para garantizar que se carguen la cantidad y la orientación correctas de productos en cada blíster.

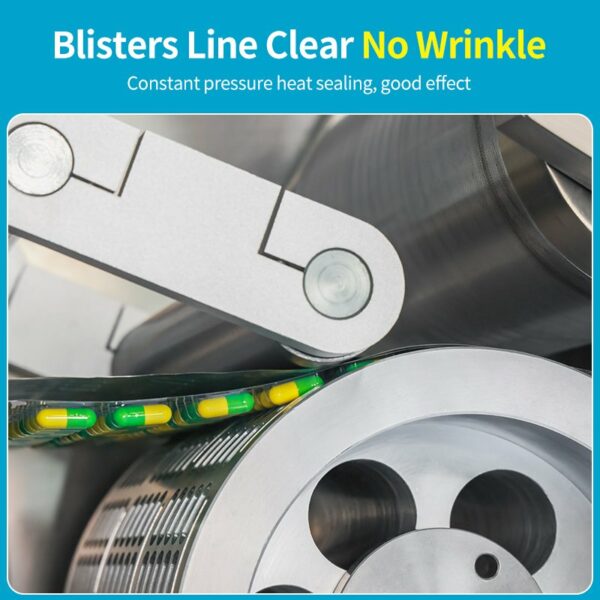

Respaldo de aluminio: Tras la carga de los productos, la película blíster se traslada a la sección de sellado. Se desenrolla un material de respaldo, generalmente papel de aluminio, y se coloca sobre las bolsas blíster formadas.

Corte de blíster: una vez sellados los blísteres, cada blíster individual se corta en unidades separadas utilizando una matriz rotatoria o un cortador de guillotina.

Especificación:

Hasta 27.000 blísteres/min

Aplicable para tabletas, cápsulas y medicamentos, etc.

Entrega rápida en 15 días