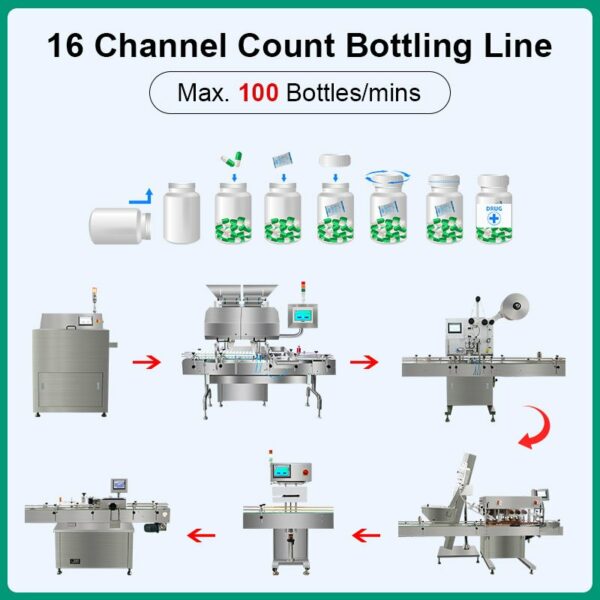

Línea de embotellado de cápsulas

Línea de embotellado de cápsulas componentes :

Posicionador de botellas: Las botellas se introducen automáticamente en la línea mediante un transportador o un plato giratorio.

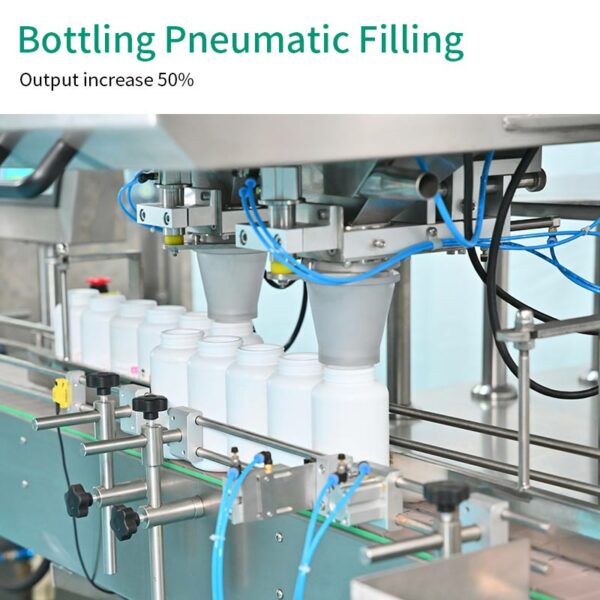

Máquina contadora: las cápsulas se llenan en botellas después del conteo.

Insertador de desecante: inserta paquetes de desecante en las botellas para mantener la estabilidad de la cápsula y evitar daños por humedad.

Máquina tapadora: tapa automáticamente las botellas llenas para sellarlas.

Máquina selladora por inducción: Sella la botella con una capa de aluminio para garantizar la seguridad y preservar la frescura del producto.

Máquina etiquetadora: Aplica etiquetas a las botellas con información del producto, números de lote, fechas de vencimiento y códigos de barras.

Especificación:

Hasta 100 botellas/min

tasa de precisión > 99.98%

Adecuado para cápsulas/tabletas/gomitas de 3 a 40 mm.