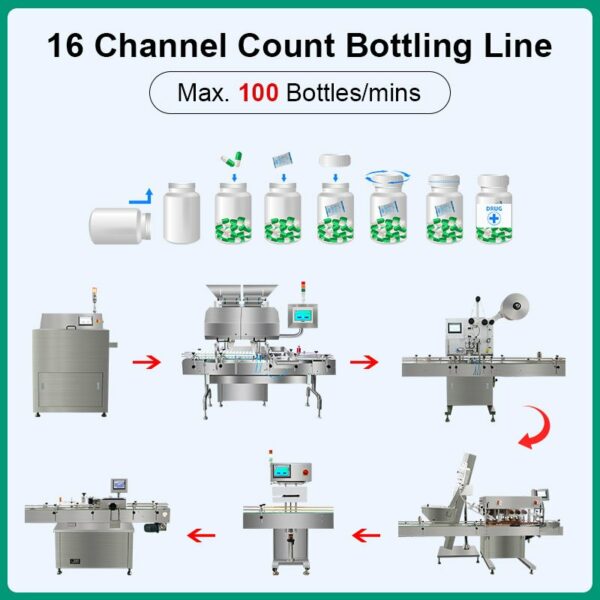

Línea de producción de conteo de cápsulas y tabletas

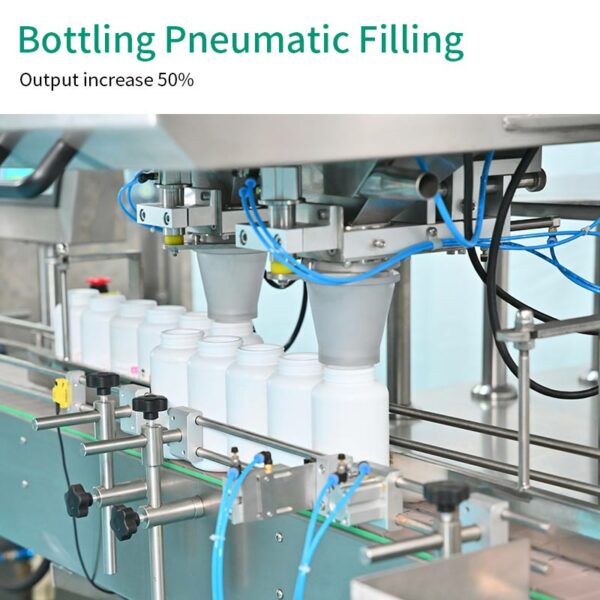

La línea de producción de conteo de cápsulas y tabletas es un sistema integrado diseñado para el conteo, llenado y envasado eficiente de tabletas o cápsulas en industrias como la farmacéutica, la nutracéutica y la atención médica.

Industria farmacéutica: Se utiliza para envasar medicamentos con y sin receta en forma de tabletas o cápsulas.

Industria nutracéutica: ideal para contar y envasar vitaminas, suplementos y otros productos relacionados con la salud.

Industria de la salud: Se emplea para envasar diversos productos de atención médica, incluidos suplementos dietéticos y medicamentos a base de hierbas.

En general, línea de embotellado de conteo es una solución esencial para los fabricantes que buscan optimizar sus procesos de envasado manteniendo altos niveles de precisión y calidad.

Especificación:

Hasta 100 botellas/min

tasa de precisión > 99.98%

Adecuado para cápsulas/tabletas/gomitas de 3 a 40 mm.