- Hogar

- Máquina llenadora de cápsulas

Máquina llenadora de cápsulas

Clasificación de la máquina llenadora de cápsulas

| Modelo de máquina | NJP-400C | NJP-800C | NJP-1500D | NJP-2600C | NJP-3800D | NJP-5500C |

| Salida máxima | 24000 piezas/hora | 48000 piezas/hora | 90000 piezas/hora | 150000 piezas/hora | 228000 piezas/hora | 330000 piezas/hora |

| Compatibilidad de tamaños de cápsulas | 000,00,0,1,2,3,4,5# | |||||

| Fuerza | 3 kW | 5 kW | 5,5 kW | 8 kW | 10,5 kW | 11 kW |

| Peso | 600 kg | 900 kg | 1200 kg | 1500 kg | 2200 kg | 3000 kg |

| Dimensión | 1000×710×1900 mm | 1100×910×2100 mm | 1490×1260×2150 mm | 1650×1490×2150 mm | 1980×1850×2200 mm | 2400x2050x2300mm |

| Modelo | CGN-208 | CGNT-209 |

| Producción | 15000-30000 piezas/hora | 40000 piezas/hora |

| Cápsula aplicable | 000#, 00#, 0#, 1#, 2#, 3#, 4#, 5# | |

| Fuente de alimentación | 2,12 kW | 2,2 kW |

| Fuerza | 380/220 V 50 Hz (personalizable) | |

| Peso neto | 400 kilos | 405 kilos |

| Tamaño del embalaje | 1640*720*1700 mm | 1640*720*1700 mm |

| Modelo | CGNL-300 | NJPL-100C | NJPL-300C | NJPL-600C |

| Producción | 15000-28000 piezas/hora | 100 piezas/min | 300 piezas/min | 600 piezas/min |

| Compatibilidad de tamaños de cápsulas | 00#, 0#, 1#, 2#, 3# | |||

| Potencia total | 2,12 kW | 3,5 kW | 5 kW | 6 kW |

| Fuerza | 380/220 V 50 Hz (personalizable) | |||

| Peso | 400 kilos | 500 kilos | 750 kg | 900 kg |

| Dimensiones (largo x ancho x alto) | 1300*800*1750 mm | 700*800*1700 mm | 860*960*1800 mm | 960*1000*1900 mm |

¿No está seguro de qué máquina es la mejor para usted? ¡Nuestro equipo puede hacerle una propuesta adaptada a sus necesidades y presupuesto!

Máquina automática de llenado de cápsulas

Beneficios

- Menos costos laborales

- Mayor rendimiento que el modelo semiautomático con un solo operador

- Automatización integrada para completar la cápsula

- Todo el proceso sin contaminación

Solicitud:

- Tamaño: #000 a #5

- Ingredientes: pellet, polvo, gránulo

Máquina llenadora de cápsulas semiautomática

- Fácil de usar

- Costos de maquinaria más bajos

- Mayor producción con más operadores

- Tamaño: #000 a #5

- Ingredientes: pellet, polvo, gránulo

Máquina llenadora de cápsulas semiautomática

Semi automatic capsule filler machine can fill powder, granule, pellet and liquid into hard capsule, suitable for capsule size ...

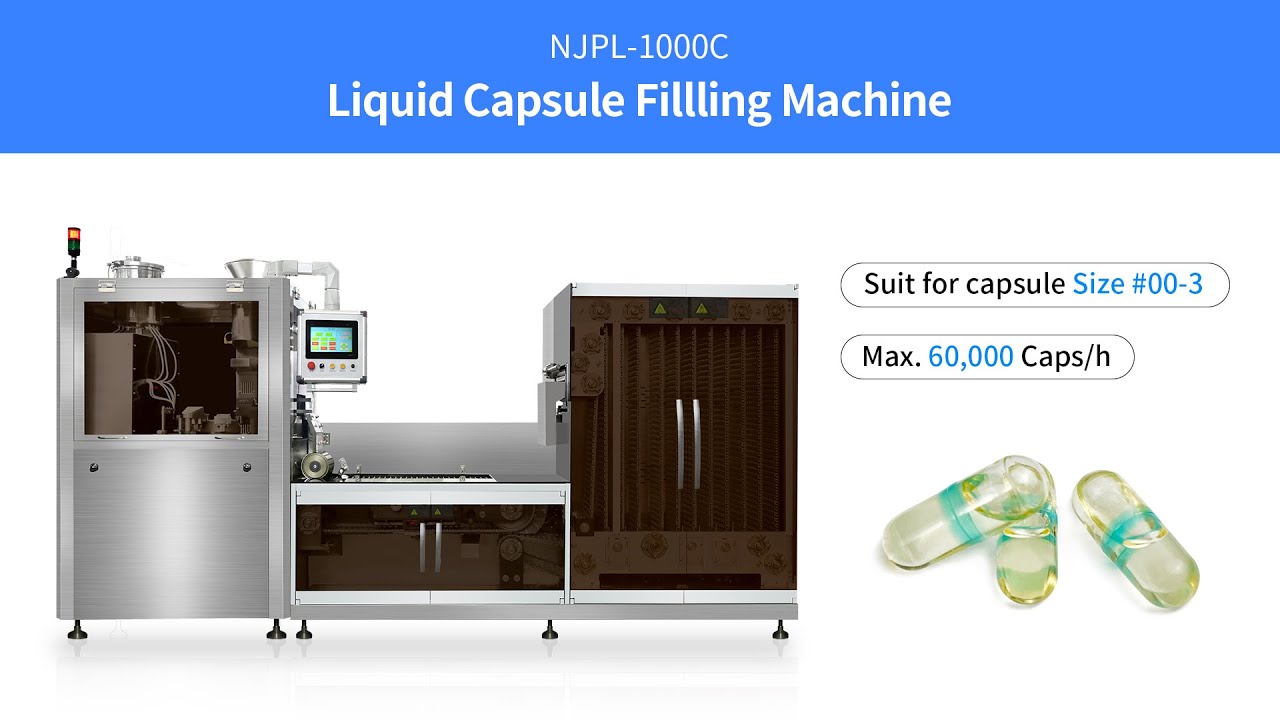

Máquina llenadora de cápsulas líquidas

Beneficios

- Últimas tecnologías sin fugas

- Todo el proceso sin contaminación

- Varias aplicaciones de líquidos

Solicitud:

- Tamaño: #000 a #3

- Ingredientes: líquido, aceite, líquido/mini cápsula, líquido/mini tableta, líquido/gránulo

NJPL-330C Automatic Liquid Capsule Filling Machine

NJPL-330C Automatic Liquid Capsule Filling Machine fills and seals oils, suspensions, pastes, and viscous solutions into hard capsules (sizes ...

Una inversión inteligente para la industria farmacéutica

Amplia aplicación

Alta precisión

Rentable

Taller sin desorden

Le respaldamos con un servicio integral

Garantía de por vida

Entrega rápida en 7 días

Servicio en línea 24/7

Preguntas frecuentes

- Lubrique la leva periódicamente para mantenerla en buenas condiciones.

- Desmontar y limpiar la estación de llenado para eliminar el exceso de material y evitar bloqueos y oxidación, una vez finalizada la producción.

- Agregue aceite lubricante a la bomba de vacío periódicamente y limpie el polvo.

- Llene regularmente el tanque de agua con suficiente agua como para sobrepasar la mitad del cuerpo del barril.

Principio de funcionamiento de la máquina llenadora de cápsulas

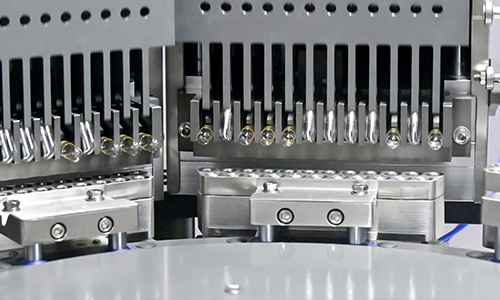

Paso #1: Separación de la cápsula

La máquina separa las cápsulas vacías en mitades individuales, generalmente utilizando mecanismos mecánicos o basados en vacío.

Paso #2: Material de relleno

El material de relleno deseado, como polvos o gránulos, se carga en una tolva.

Paso #3: Cierre de la cápsula

La máquina junta las mitades de la cápsula, las alinea y las cierra de forma segura mediante presión mecánica, succión al vacío o una combinación de ambas.

Paso #4: Expulsión

Una vez cerradas las cápsulas, se liberan de la máquina, ya sea a un contenedor o para su posterior envasado.

¿Qué es la máquina llenadora de cápsulas?

Una máquina llenadora de cápsulas es un dispositivo utilizado en la farmacéutico, nutracéutico, y industrias herbarias para automatizar el proceso de llenado de cápsulas vacías con diversas sustancias como polvos, gránulos, pellets o líquidos.

Se compone de diferentes componentes, entre ellos una tolva de cápsulas, un mecanismo para separar y orientar las cápsulas, un sistema de llenado, un mecanismo de cierre y un sistema de expulsión.

La máquina facilita un llenado eficiente y preciso de cápsulas, Garantizar una dosificación precisa y uniformidadAyuda a aumentar la velocidad de producción, reducir los costos laborales y mantener el control de calidad en los procesos de fabricación de cápsulas.

Principales tipos de cápsulas

Cápsulas de cubierta dura

- Las cápsulas de cubierta dura, también conocidas como cápsulas de dos piezas, se componen de tapa y cuerpo separados que encajan para contener el material de relleno. La tapa y el cuerpo suelen estar hechos de gelatina o materiales vegetales.

- Las cápsulas duras ofrecen excelente protección, estabilidad y precinto de seguridad. Se utilizan comúnmente para polvos secos, gránulos o pequeñas partículas sólidas.

Cápsulas de cubierta blanda

- Las cápsulas blandas están compuestas por una única cubierta flexible de gelatina o vegetal. Se las conoce comúnmente como cápsulas blandas. Las cápsulas blandas suelen contener materiales líquidos o semisólidos, como aceites, suspensiones o pastas.

- La cubierta blanda proporciona ventajas como una biodisponibilidad mejorada para formulaciones basadas en lípidos, una estabilidad mejorada para compuestos sensibles a la luz y facilidad de deglución.