Automatic counting machines are a vital component of the pharmaceutical industry’s packaging process. These machines play a crucial role in accurately counting, relleno, and packaging medication in various forms such as tabletas, cápsulas, and powders.

Pharmaceutical packaging is a critical aspect of the industry, as it not only assures the quality and safety of the medication but also helps to maintain the efficacy of the product while being transported and stored. Packaging can involve different stages, including material selection and process development, which can affect medication formulations, duración, and stability. Como consecuencia, the use of advanced technologies such as automatic counting machines can significantly improve the quality and reliability of pharmaceutical packaging.

Beneficio 1: Efficiency and accuracy in counting

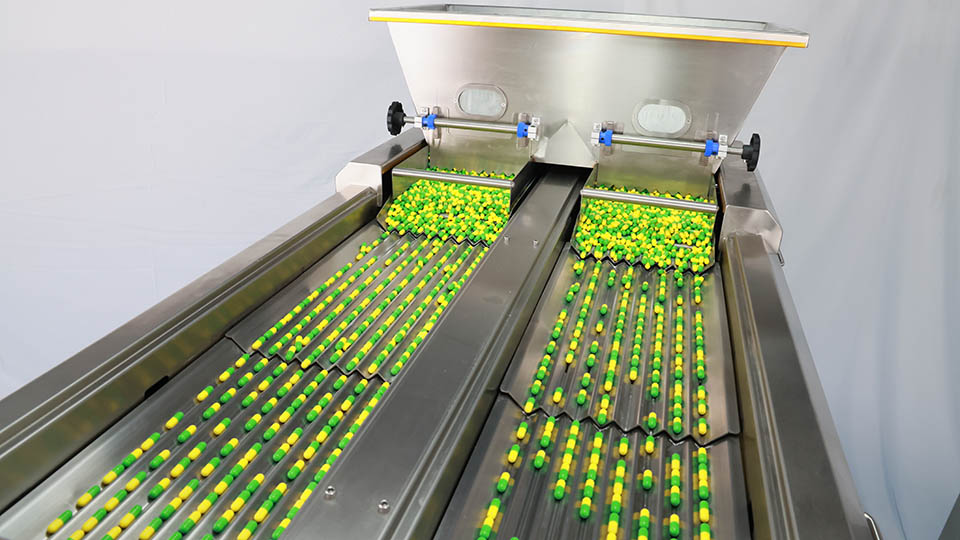

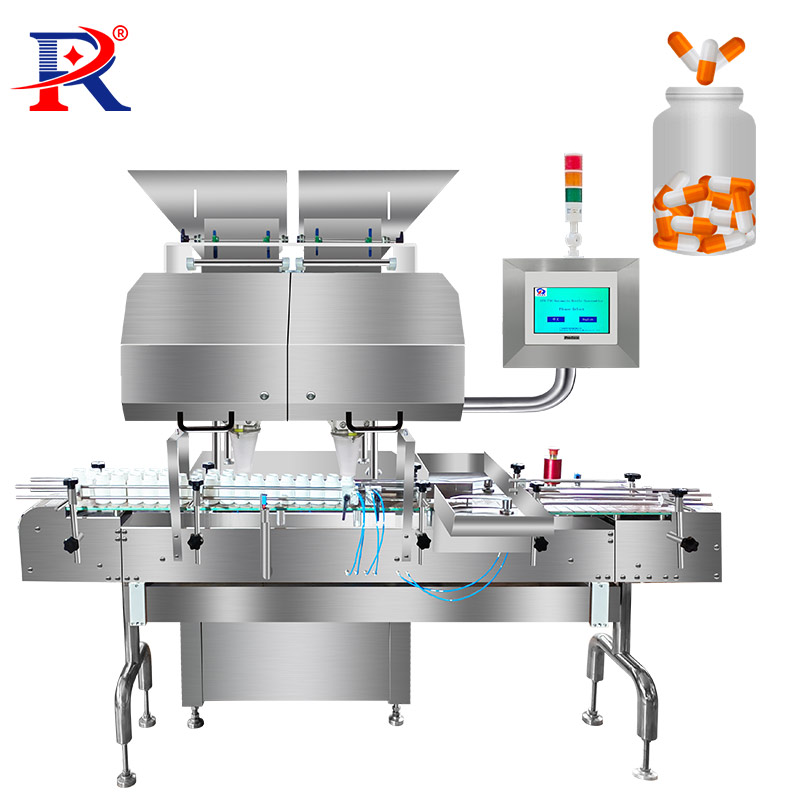

Automatic counting machines are capable of accurately counting and packaging medications with velocidad, eficiencia, and consistency. These machines use advanced technology, such as sensors and robotics, to ensure precise and accurate counting, sorting, and packaging of medications, regardless of the form in which they are delivered. With the ability to operate at high speeds, automatic counting machines can significantly increase the productivity of the pharmaceutical packaging process while maintaining high levels of accuracy and efficiency.

Comparison with Manual Counting

In contrast to automatic counting machines, manual counting processes are often time-consuming, labor-intensive, and less accurate. Manual counting processes can result in inconsistencies in the counting and packaging of medications, which can lead to costly errors, safety concerns, and decreased efficiency.

Por ejemplo, manual counting processes may result in variations in the number of tablets or capsules in a package, leading to dosage errors and medication waste. Además, manual processes can be prone to human error, which can result in inaccurate label data or incorrect packaging.

Overall, the use of automatic counting machines can offer significant benefits over manual counting processes, including increased efficiency, exactitud, and greater consistency in the packaging of medication. These benefits can lead to cost savings for pharmaceutical companies, improved medication safety and quality for patients, and greater overall productivity in the industry.

Beneficio 2: Increased productivity

Automatic counting machines can significantly increase productivity and throughput rates in the pharmaceutical industry. These machines operate at a faster pace and with greater accuracy than manual counting processes. With automatic counting machines, the pharmaceutical packaging process can be completed more quickly and efficiently, allowing for larger quantities of medication to be packaged and shipped in less time.

How Automatic Counters Speed up the Packaging Process

Automatic counting machines can speed up the packaging process by quickly and accurately counting medications in different forms, incluido tabletas, cápsulas, and powders. They can sort and package the medication at a much faster rate than manual processes, which can be time-consuming and prone to errors.

Además, some automatic counting machines can be integrated into larger production lines, allowing for uninterrupted, high-speed production and packaging. Overall, automatic counting machines offer a key advantage in boosting productivity in the pharmaceutical industry.

Beneficio 3: Reduced Labor Costs

Automatic counting machines can significantly reduce labor costs in the pharmaceutical industry by automating the packaging process, reducing the need for manual labor. With an automatic counting machine, the need for human labor in the counting, sorting, and packaging of medication can be significantly reduced, or even eliminated. This results in lower labor costs for pharmaceutical companies, as they can avoid the expenses associated with hiring and retaining manual labor.

Además, automatic counting machines are able to operate continuously without breaks, minimizing the risk of worker fatigue and injury. Este reduces the need for additional hires to cover shifts or downtime associated with manual labor. Como resultado, pharmaceutical companies can achieve cost savings through reduced labor costs, while also improving production rates and efficiency.

Beneficio 4: Versatility with different types of products

Automatic counting machines are highly versatile in their ability to count and package various types of medication products with different shapes, tamaños, and forms. These machines are capable of counting and packaging tablets, cápsulas, soft gels, and even irregularly shaped objects, such as oblong tablets or gel caps.

The versatility of these machines is attributed to their advanced technology, including sensors and software algorithms, which enable the machines to accurately count and sort different types of medication products. Automatic counting machines also allow for flexibility in packaging options, such as the ability to package medication in blister packs, botellas, or pouches.

Automatic counting machines are capable of counting and packaging various types of medication products, including but not limited to:

- tabletas: Automatic counting machines can accurately count and package tablets of different sizes and shapes, incluyendo ronda, oval, and oblong tablets.

- Cápsulas: These machines can count and package various types of capsules, including hard gelatin capsules, soft gel capsules, and vegetable capsules.

- Soft gels: Automatic counting machines can count and package soft gel products, which are typically more challenging to count manually due to their pliability.

- Irregularly shaped objects: These machines have the ability to count and package irregularly shaped objects, such as oblong tablets or gel caps, with accuracy and precision.

Overall, the versatility of automatic counting machines allows pharmaceutical companies to package a wide variety of medication products efficiently and accurately, while reducing the risk of errors and increasing overall productivity.

Beneficio 5: Cost-effectiveness

Automatic counting machines can be a cost-effective solution for pharmaceutical companies, as they reducir los costos laborales, improve productivity, and minimize the risk of errors. By automating the packaging process, these machines can perform the work of multiple employees efficiently and accurately. This can lead to significant cost savings for pharmaceutical companies, as they can avoid the need to hire additional labor, increase production rates, and reduce the risk of costly errors.

Automatic counting machines can also reduce costs associated with packaging materials, as they can use materials in a more precise and efficient manner, reducing wastage. This can result in overall cost savings and a reduction in the environmental impact of the company’s packaging operations.

Overall, automatic counting machines offer a cost-effective solution for packaging medication, as they improve productivity, eficiencia, and accuracy, while reducing labor costs and minimizing the risk of errors. With the ability to package a wide variety of medication products, pharmaceutical companies can benefit from the cost savings and improved productivity that these machines offer.

Beneficio 6: High-quality packaging

Automatic counting machines improve the quality of packaging in the pharmaceutical industry by accurately counting and sorting medication products. These machines use advanced technology, such as sensors and robotics, to reliably detect irregularities and make adjustments on the fly, resulting in high-quality packaging output.

By automating the packaging process, automatic counting machines also minimize the risk of errors, such as miscounts or incorrect labeling, ensuring that packaging meets regulatory requirements and is safe for patients. Además, these machines can improve the overall aesthetic and organization of packaging. The automatic counting machines can also help prevent contamination by carefully sealing and handling medication before distribution.

Automatic counting machines have sophisticated systems that allow them to scan products for defects and ensure that packaging is of uniform quality. These machines provide reliable detection for:

- Missing tablets or capsules: The machine can detect empty spaces in a packaging unit and automatically correct the count.

- Damaged or broken tablets or capsules: By using sensors, automatic counting machines detect physical damage in the medication that may be in the counting process.

- Incorrect tablet or capsule orientation: The machine ensures the correct number and orientation of tablets or capsules in their packaging.

- Incorrect label placement: These machines use sensors to identify correct label placements and set correct positioning to ensure clear labeling.

- Contamination: The machines have systems to ensure the cleanliness and safety of medication containers and packaging before distributing.

Overall, automatic counting machines offer several benefits that improve the quality of packaging. By using advanced technology, these machines are able to detect and correct irregularities, preventing errors and making sure packaging is safe for distribution.

Conclusión

Automatic counting machines are crucial in the pharmaceutical industry as they provide highly accurate and efficient solutions for medication packaging. Their ability to perform repetitive tasks with precision, detect and correct irregularities, and ensure medication safety, makes them indispensable for pharmaceutical companies.

Through automation, these machines have revolutionized the packaging industry and improved the quality and safety of medication products. With their cost-effectiveness, flexibility, y versatilidad, automatic counting machines offer significant advantages for pharmaceutical companies looking to improve efficiency while maintaining high-quality standards.