- Home

- Tablet Press Machine

Rotary Tablet Press Machine

Rotary tablet press machine is widely used in the pharmaceutical, nutraceutical, and chemical industries to compress powders into uniform tablets. It is essential for producing tablets of precise weight, size, and shape, ensuring consistent dosage and quality. Tablet presses are used for medications, supplements, vitamins, and even certain confectionery products, providing efficient and high-speed production with options for single-layer or multi-layer tablets.

Application:

How Rotary Tablet Press Machine works?

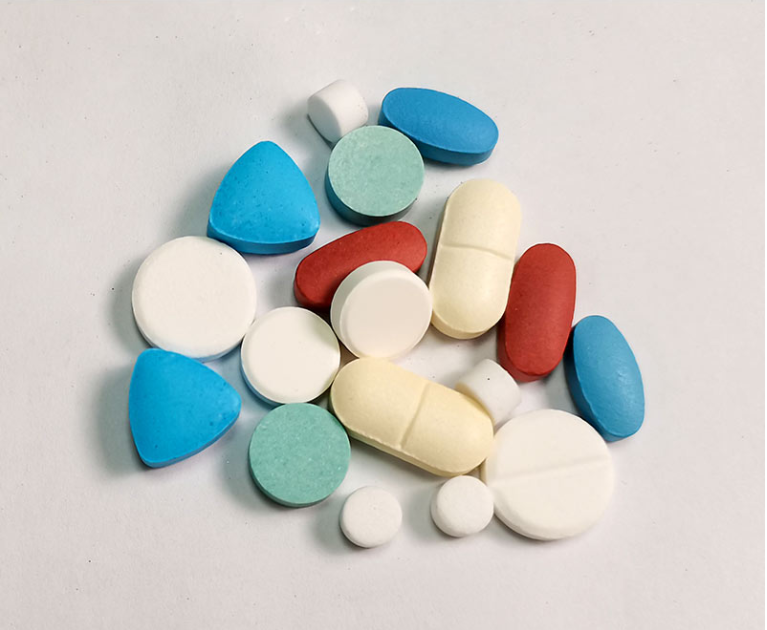

Tablet press can efficiently press powder and granules into tablets with diverse diameters and thicknesses. And with customized dies, the ingredients can even be pressed into different shapes for your needs, such as round, triangle, core rod, and special-shaped tablets.

The Complete Range of Tablet Press Machines

| Model | Dies No. | Output/h | Punch Pressure | Max.Tablet Diameter | Max.Tablet Thickness | Dimension(mm) | Weight(kg) | Total Power |

| ZP-15D | 15 | 18000 | 120KN | 50mm | 25mm | 1250*980*1650 | 1850 | 7.5KW |

| ZP-17D | 17 | 30600 | 60KN | 20mm | 6mm | 890*650*1680 | 1000 | 3.0KW |

| ZP-20 | 20 | 40000 | 80KN | 25mm | 8mm | 840*1015*1720 | 1200 | 4KW |

| ZP-25D | 25 | 90000 | 100KN | 25mm | 15mm | 1240*850*1850 | 1850 | 5.5KW |

| ZP-27D | 27 | 90000 | 120KN | 25mm | 17mm | 1040*910*1690 | 1600 | 7.5KW |

| ZP-29D | 29 | 110000 | 100KN | 24mm | 12mm | 1040*910*1690 | 1600 | 5.5KW |

| ZP-41/51/55 | 55 | 260000 | 120KN,pre:20KN | 13mm | 8mm | 1220*1120*1980 | 2100 | 7.5KW |

A Helping Hand for Your Long-term Business

We've Got Your Back with Comprehensive Service

Life-time Guarantee

Fast Delivery in 7 Days

24/7 Online Service

Frequently Asked Questions

- To prevent rusting, the die can be disassembled and soaked in oil when it is not in use.

- Clean the turntable and die completely after the whole production is finished.

- Lubricated the guide rail, turntable, and die regularly.

- The vacuum cleaner should be cleaned in time.

Types of Tablet in Pharmacy

Pills are a general term for solid dosage forms that are shaped into small, and round forms. They can be swallowed whole and typically have a smooth surface.

A caplet is a smooth, coated, oval-shaped medicinal tablet in the general shape of a capsule. They are easier to swallow compared to regular tablets due to their smooth shape.

ODTs, also known as Orodispersible or Dissolving tablets, are designed to disintegrate rapidly in the mouth. They are intended to be taken without water, making them suitable for individuals who have difficulty swallowing.

Film-coated tablets have a thin layer of polymer or resin applied to the surface of the tablet. The coating can enhance the appearance, mask taste or odors, and protect the tablet from moisture or chemical degradation.

Applications of Rotary Tablet Machine

Pharmaceutical Industry

Nutraceutical Industry

Veterinary Medicines

Herbal & Ayurvedic Products

Industrial Applications

Capsule vs. Tablet, Which Is Better?

| Factors | Capsules | Tablets |

|---|---|---|

| Composition | Gelatin-based shells or vegetarian alternatives | Compressed powders, granules, or solid formulations |

| Ease of Swallowing | Generally easy to swallow | Can be difficult for some individuals to swallow |

| Disintegration Time | Faster disintegration and drug release | Disintegration time may vary based on formulation |

| Taste and Odor | Capsules can mask the taste and odor of the content | Taste and odor of the formulation may be noticeable |

| Stability | Some capsules may be less stable over time | Tablets can have longer shelf life if properly made |

| Production Efficiency | Faster and automated filling process | Requires additional steps like compression and coating |

| Splitting/Dividing | Not easily divided into smaller doses | Can be divided into halves or quarters if necessary |

| Branding Potential | Capsule color and transparency can enhance branding | Shape, size, and coatings can enhance branding |