Yan Yüklemeli Kartonlama Makinesi

Side Load Cartoner is a vital piece of equipment used in packaging processes, designed to automatically form, fill, and seal cartons for a variety of products, including pharmaceuticals, food, cosmetics, and consumer goods. Also can connected line of blister paketleme makinesi and pillow packing machine.

Cartoning machines can handle various carton sizes and styles, including foldable cartons, display boxes, and special-shaped cartons. They typically operate in a continuous or intermittent motion, allowing for high-speed production while maintaining accuracy in product placement and sealing.

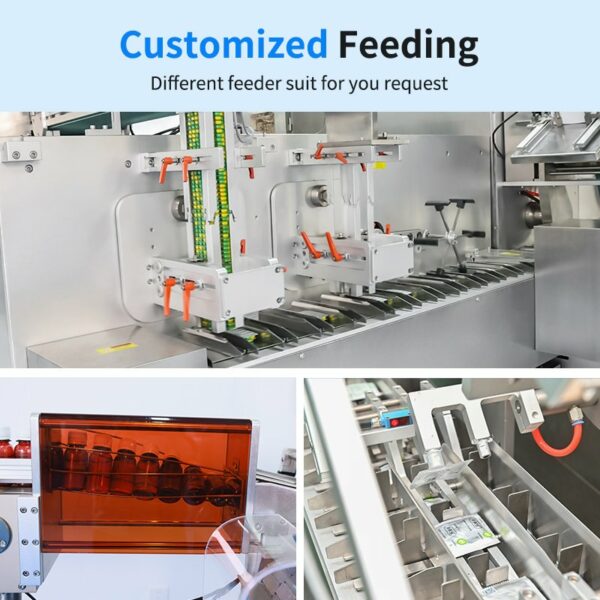

The process generally involves feeding flat cartons into the machine, where they are formed into a three-dimensional shape, filled with products, and then sealed, often with glue or tuck-flap closure. Advanced models feature integrated systems for quality control, ensuring proper filling and secure sealing to prevent product tampering or contamination.

With the ability to accommodate diverse packaging needs, cartoning machines are essential for businesses looking to optimize their packaging operations while maintaining product integrity and compliance with industry standards.

Şartname:

Dakikada 120 kartona kadar

Bister Tabak, Şişe, Poşet vb. İçin Uygulanabilir

15 Gün Hızlı Teslimat