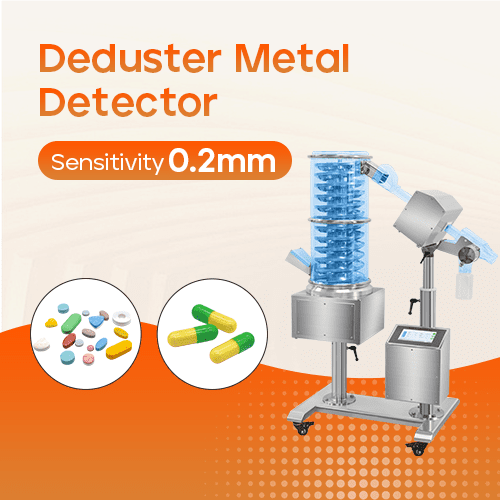

In the pharmaceutical and nutraceutical industries, product safety is non-negotiable. A single metal contaminant—a fragment of a worn machine part, a wire, or a stray piece of stainless steel—can have severe consequences. The Tablet Deduster Metal Detection Machine is a critical line of defense, but its effectiveness hinges on its precision. Many factors can interfere with its accuracy, compromising your product’s integrity.

Understanding these factors is essential for maintaining optimal performance and ensuring unwavering consumer safety.

1. The Machine’s Own Construction and Material

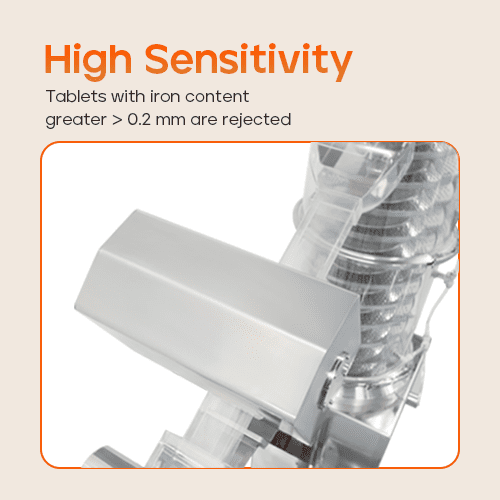

Paradoxically, the very materials used to build the metal detector can become a problem. If the housing, conveyor, or reject mechanism near the aperture (detection head) is made from ferrous or non-ferrous metals, it can create a persistent magnetic field that interferes with the detector’s sensitive balance. High-quality detectors are constructed with non-metallic, food-grade, and hygienic materials in critical areas to ensure their own structure doesn’t become a source of noise and false signals, allowing them to focus solely on detecting contaminants in the product.

2. External Environmental Interference

The detection aperture works by generating a balanced electromagnetic field. Any external variable that disrupts this field will impact accuracy.

People and Moving Equipment: As personnel walk by or forklifts drive near the machine, they can introduce moving metal, causing the detector to trigger false rejects. Even stationary large metal objects like racks or other machinery can distort the field if they are too close.

Vibrations and Ground Stability: Operating on an uneven floor or in close proximity to heavy, vibrating equipment like tablet presses or granulators can cause physical shaking. This movement alters the precise calibration of the detection aperture, leading to inconsistent performance and a failure to reject contaminated product.

Electrical Noise: Other high-power devices on the same circuit—motors, compressors, or welding equipment—can cause “electrical noise,” disrupting the stable power supply the detector needs to function accurately.

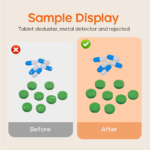

3. The “Product Effect” of Dust and Moisture

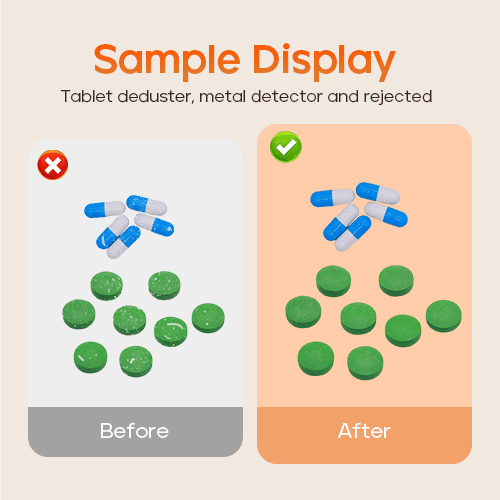

Tablets themselves can be a source of interference. The core function of the deduster is to mitigate this. A layer of dust around a tablet is conductive and can create a signal that mimics a metal contaminant. If the dedusting system is inefficient, this “product effect” can cause two major issues: the machine might wrongly reject good product (increasing waste), or its sensitivity might have to be lowered to ignore the dust, which risks allowing small metal particles to pass through undetected.

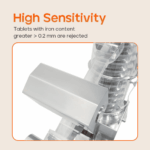

4. Improper Calibration and Maintenance

A metal detector is not a “set it and forget it” device. Over time, normal wear and tear can cause calibration to drift. Failing to perform regular sensitivity checks with certified test samples (e.g., ferrous, non-ferrous, and stainless steel rods of known sizes) means you are operating blind. Furthermore, a buildup of product residue or dust on the aperture can affect its electromagnetic field, making routine cleaning a critical part of the accuracy protocol.

Hazards to Human Health

Neglecting these factors isn’t just a operational hiccup; it’s a serious safety gamble. If a metal-contaminated tablet reaches a consumer, the results can be catastrophic:

Internal Injuries: Sharp metal shards can cause lacerations to the mouth, throat, esophagus, stomach, or intestines.

Choking and Dental Damage: Larger metal pieces can pose a choking hazard or break teeth.

Toxic Reactions: Certain metals can leach into the body, leading to poisoning over time.

Beyond the dire human cost, a single contamination incident can lead to massive product recalls, devastating lawsuits, irreversible brand reputation damage, and stringent regulatory action from bodies like the FDA and EMA.

Protect Your Product, Your Consumers, and Your Brand

The path to safety is clear: invest in a well-designed Tablet Deduster Metal Detection Machine, install it correctly in a stable environment away from interference, and commit to a rigorous routine of maintenance and calibration.