मेडिकल टैबलेट बनाने की मशीन

Medical tablet making machine operate on a systematic compression mechanism to create tablets of consistent size, weight, and hardness. Here’s a breakdown of the working principle:

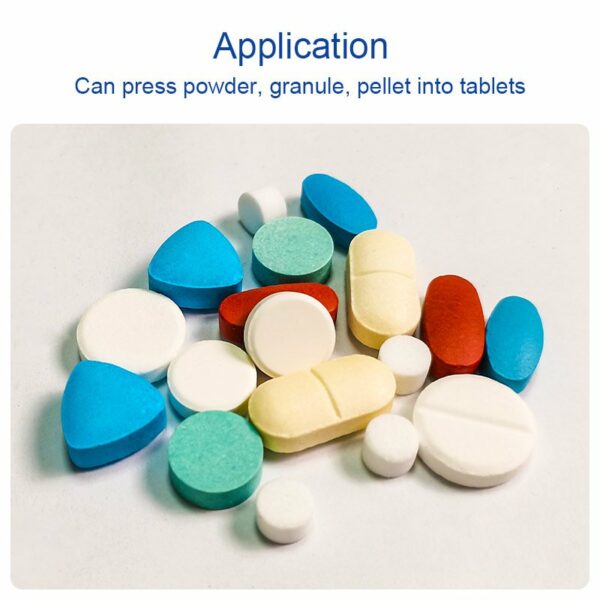

Feeding & Die Filling: Powder or granules are fed into a hopper, which directs the material into a rotating die system. The dies are cavities that determine the tablet’s shape and size.

Pre-Compression: Initial pressure is applied to remove air pockets, ensuring uniform density.

Main Compression: Upper and lower punches exert high pressure (up to 100 kN) to compact the powder into a solid tablet.

Ejection: The finished tablet is pushed out of the die and collected for packaging.

Modern rotary tablet presses automate this process, achieving speeds of 10,000–900,000 pcs/h. Advanced models integrate force control systems and real-time monitoring to maintain quality compliance with FDA or GMP standards.

विशिष्टता:

110,000 टैब्स/घंटा तक

टैबलेट का अधिकतम व्यास 24 मिमी

15 दिन में त्वरित डिलीवरी