Máquina automática de llenado de cápsulas NJP-400C

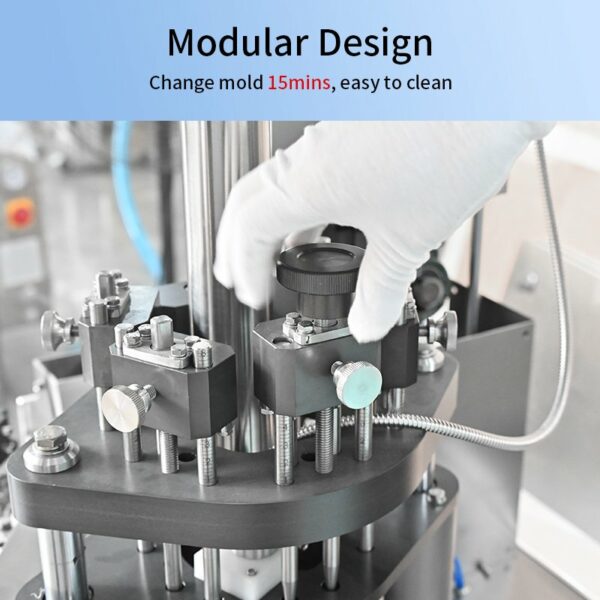

La encapsuladora automática NJP-400C puede encapsular polvo, gránulos y pellets en cápsulas duras. El mecanismo de llenado adopta un diseño modular, lo que facilita la limpieza y el mantenimiento; la escala es ajustable y la precisión de llenado es inferior a 0,1 mm. El diseño del plato giratorio cuenta con una patente de modelo de utilidad. La encapsuladora utiliza anillos de sellado de caucho y silicona importados por SIL para evitar eficazmente la entrada de polvo farmacéutico en el interior del plato giratorio. Ofrece un buen rendimiento de sellado y evita derrames de polvo y contaminación. Los ejes transversales dobles del plato giratorio utilizan cojinetes de politetrafluoroetileno sin aceite, que no requieren aceite ni mantenimiento de por vida.

Equipado con máquina de alimentación de cápsulas al vacío, máquina de alimentación de polvo y máquina pulidora. Máquina llenadora de cápsulas completamente automática Cumple con los requisitos cGMP, lo que lo convierte en un equipo ideal para el llenado de medicamentos y nutrientes.

Especificación:

Hasta 24000 piezas/h

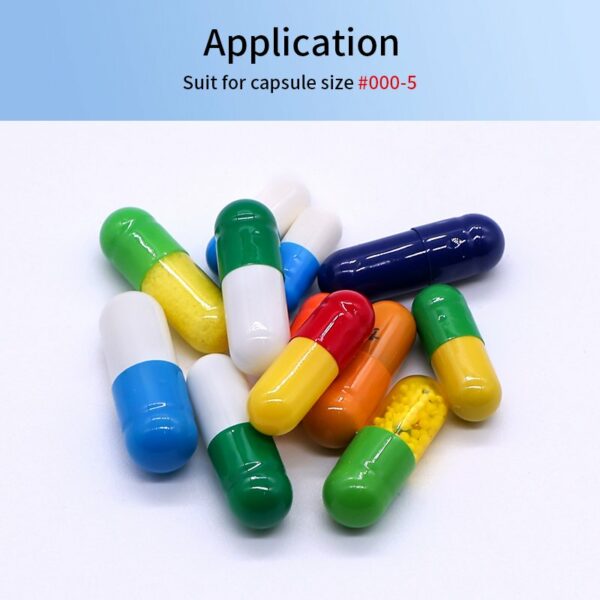

Aplicable para #000 ~ 5 cápsulas

Entrega rápida en 15 días

Adecuado para polvo, gránulos, pellets y tabletas.