Máquina para fabricar tabletas médicas

Las máquinas de fabricación de comprimidos médicos funcionan mediante un mecanismo de compresión sistemática para crear comprimidos de tamaño, peso y dureza uniformes. He aquí un desglose del principio de funcionamiento:

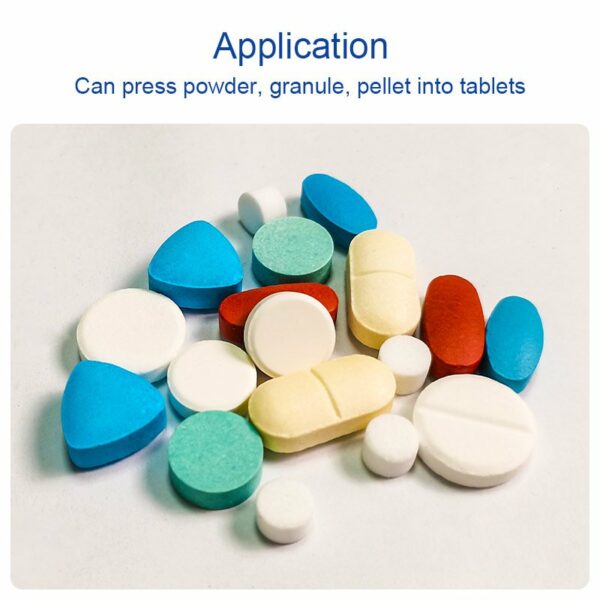

Alimentación y llenado de troqueles: El polvo o los gránulos se introducen en una tolva, que dirige el material hacia un sistema de troqueles giratorios. Las matrices son cavidades que determinan la forma y el tamaño del comprimido.

Precompresión: Se aplica una presión inicial para eliminar las bolsas de aire, asegurando una densidad uniforme.

Compresión principal: Los punzones superior e inferior ejercen una alta presión (hasta 100 kN) para compactar el polvo y convertirlo en una pastilla sólida.

Expulsión: La pastilla acabada se empuja fuera de la matriz y se recoge para su envasado.

Las modernas comprimidoras rotativas automatizan este proceso, alcanzando velocidades de 10.000-900.000 unidades/hora. Los modelos avanzados integran sistemas de control de fuerza y supervisión en tiempo real para mantener la calidad conforme a las normas FDA o GMP.

Especificación:

Hasta 110.000 pestañas/h

Diámetro máximo de la tableta: 24 mm

Entrega rápida en 15 días