Máquina de recubrimiento de tabletas de alta eficiencia

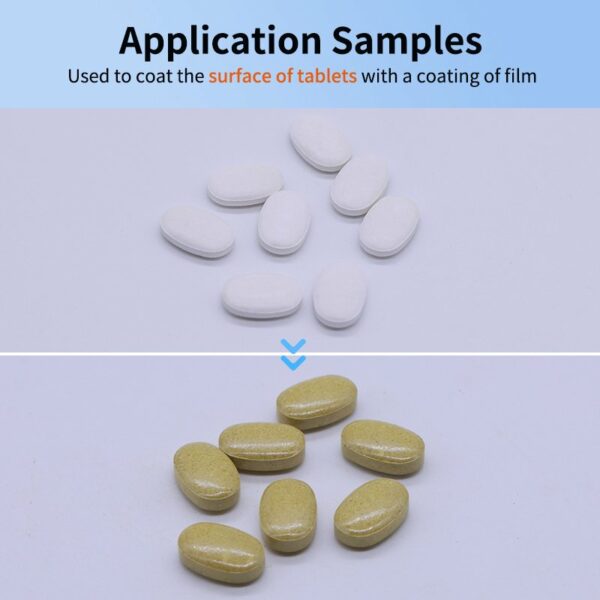

La máquina de recubrimiento de comprimidos de alta eficiencia está diseñada para aplicar una película o jarabe a los comprimidos con diversos fines, como mejorar el sabor, facilitar la ingestión o proporcionar una liberación controlada de los principios activos. Puede utilizarse en combinación con... máquina prensadora de tabletas.

Recubrimiento estándar: El método tradicional consiste en un recipiente giratorio donde las tabletas se voltean y se rocía con la solución de recubrimiento. El recubrimiento se seca con aire caliente. Apto para recubrimientos con azúcar o película.

Bandeja de recubrimiento perforada: Esta es una versión más avanzada, con perforaciones que permiten el flujo de aire y optimizan el proceso de secado. Ejemplos de estas bandejas son Accela-Cota y Driacoater.

Recubridora de lecho fluidizado: Las tabletas se suspenden en una corriente de aire y se rocían con la solución de recubrimiento. El movimiento y el secado constantes proporcionan un recubrimiento uniforme y eficiente. Apta para gránulos y pellets, no solo para tabletas.

Especificación:

Hasta 64 kg/lote

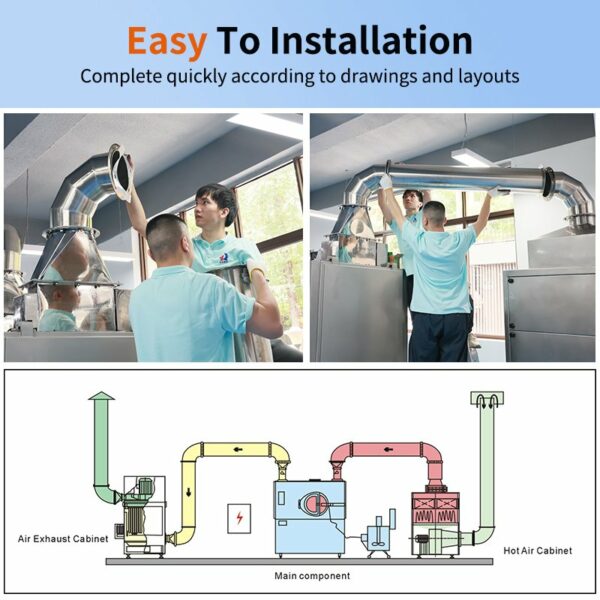

Gabinete de aire caliente

Gabinete de extracción