Máquina estuchadora de alta velocidad

Las máquinas estuchadoras de alta velocidad tienen una amplia gama de aplicaciones en diversas industrias debido a su eficiencia y capacidad para manipular diferentes tipos de productos.

Industria farmacéutica: Envasado de blísteres, botellas, tubos, viales y otros productos médicos.

Industria de alimentos y bebidas: Envasado en cartón de alimentos como barras de chocolate, galletas, barras de granola, sobres y latas.

Productos cosméticos y de cuidado personal: Envasado de artículos cosméticos como cremas, lociones, champús y productos de maquillaje en cajas de cartón para venta minorista.

Asistencia sanitaria y dispositivos médicos: Embalaje de instrumentos quirúrgicos, artículos médicos desechables y kits de atención sanitaria.

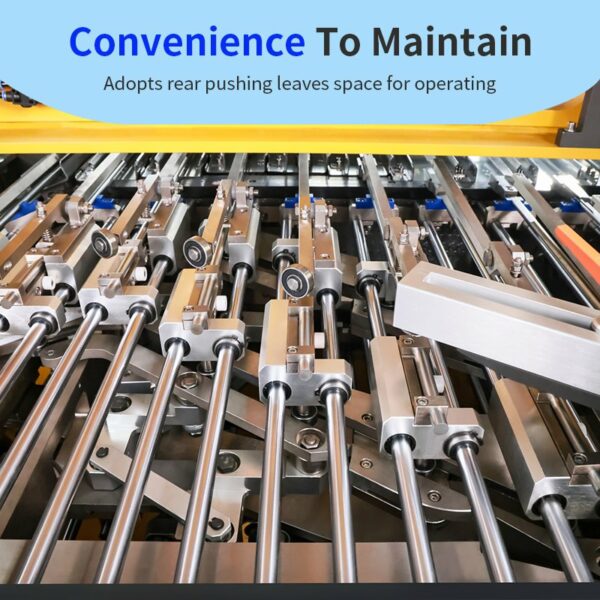

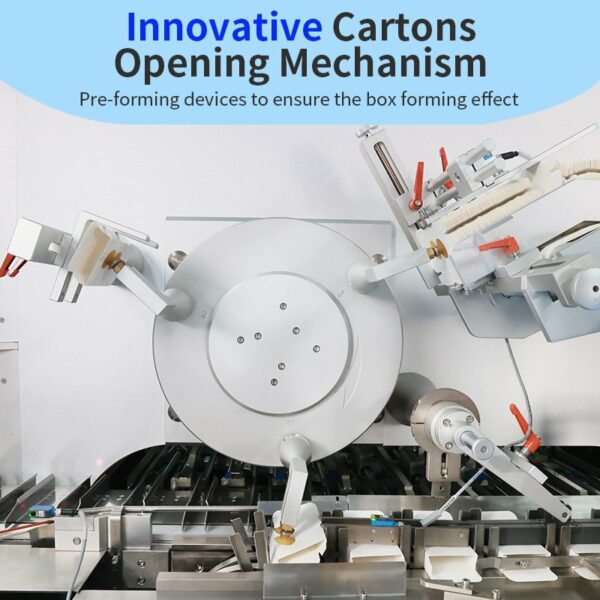

Encartonadora de alta velocidad Son valorados por su capacidad para manejar grandes volúmenes de manera eficiente, reducir el trabajo manual y mejorar la consistencia y precisión del empaque.

Especificación:

Hasta 320 cajas/min

Aplicable para platos de biberón, botellas, bolsitas, etc.

Entrega rápida en 20 días