Contador de canales Gummy

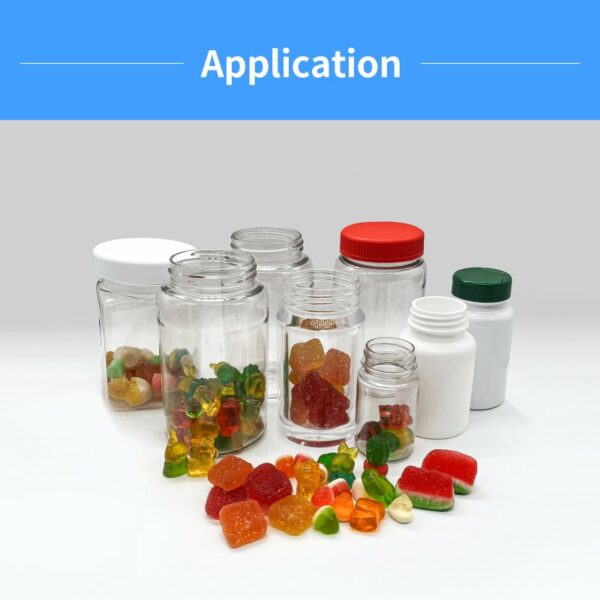

El contador de canales de gomitas es un equipo especializado diseñado para contar y dispensar con precisión productos gomosos en envases, como botellas o bolsas. Estas máquinas se utilizan comúnmente en las industrias alimentaria, nutracéutica y farmacéutica, especialmente para productos como vitaminas gomosas, suplementos y caramelos.

Conteo preciso: la función principal de una máquina contadora de gomitas es contar las gomitas con alta precisión, garantizando que cada paquete contenga la cantidad correcta de piezas.

Operación de alta velocidad: Las modernas máquinas contadoras de gomitas están diseñadas para una operación de alta velocidad, lo que permite a los fabricantes envasar de manera eficiente grandes cantidades de gomitas en poco tiempo.

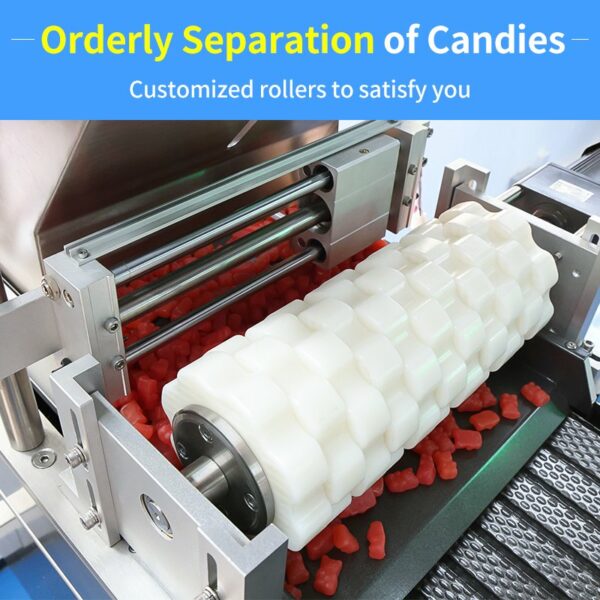

Versatilidad: A menudo están equipados con configuraciones ajustables para adaptarse a distintas dimensiones de gomitas.

Especificación:

80 botellas/min

Adecuado para pectina de 3-40 mm, azúcar, caramelos aceitados…