- Hogar

- Máquina contadora automática

Máquina contadora automática

Puede contar y envasar todo tipo de cápsulas, tabletas y gomitas en una botella, lo cual es ideal para instituciones de investigación científica, hospitales, fábricas farmacéuticas, productos de salud y envasado en fábrica. También se integra con máquinas estuchadoras, etiquetadoras, etc.

Solicitud:

La máquina contadora automática es adecuada para varias capacidades diferentes, incluidas cápsulas, tabletas y gomitas.

Cápsula (000~5#)

Tableta (3 a 40 mm)

Gomoso (3 a 40 mm)

Cómo funciona

Además de simplemente contar y llenar tabletas y cápsulas en botellas, la máquina contadora automática de Rich Packing está equipada con secciones de trabajo y tecnologías para garantizar un proceso de producción fluido y eficiente.

Clasificación de botellas

Organizando todas las botellas para la preparación del llenado.

Ingredientes del relleno

Llenando todos los materiales en la máquina contadora.

Cálculo

Alineación en canales. Se pueden contar y llenar cápsulas, tabletas o gomitas hasta 9000 botellas/h.

Inyección de pastillas

Inyectar pastillas en frascos con tecnología patentada sin escasez.

Limpieza de residuos

Limpiando aquellas botellas defectuosas.

La gama completa de máquinas contadoras automáticas

Una amplia variedad de modelos de máquinas con diferentes capacidades y presupuestos para que usted elija.

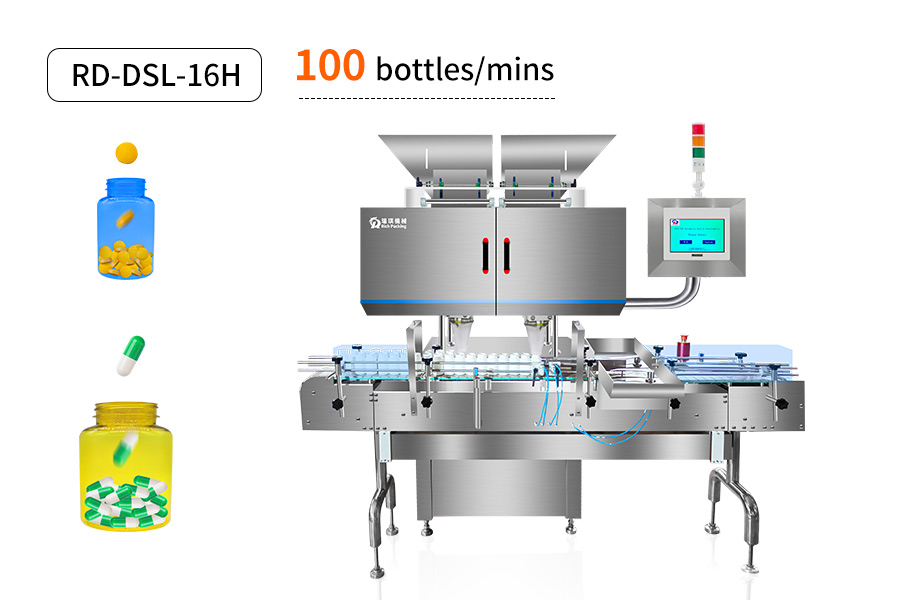

| Modelo | 8B | 12B | 16B | 16R | 16 horas | |

| Capacidad | 10-35 botellas/minuto | 15-45 botellas/minuto | 20-85 botellas/minuto | 100 botellas/minuto | 127 botellas/minuto | |

| Material capaz | Cápsula/tableta/gomita de 2-40 mm... | |||||

| Tasa de precisión | >99.8% | >99.97% | >99.98% | |||

Máquina llenadora y contadora de tabletas y cápsulas

Tablet and capsule counting filling machine involves several precise steps designed to ensure accurate counting and efficient filling into ...

¿Necesita otro modelo de máquina?

Aplicación más amplia:

Cálculo

Gomitas, caramelos…

En lugar de solo tabletas o cápsulas, nuestra máquina contadora con tecnologías especiales también puede contar y envasar suplementos nutricionales, como vitaminas e incluso gomitas. Esto amplía las posibilidades de su negocio.

- El diseño de palanca separada con deslizamiento continuo evita que se atasque.

- El revestimiento de teflón en el canal permite una entrega suave.

- Tolva ancha de PTFE sin obstrucciones gomosas

Línea de conteo completamente automática

Diseñada para operar desde el desempaquetado de la botella hasta la colocación de la etiqueta, la línea de conteo automático le ayuda a colocar sus cápsulas o tabletas en una botella con todo lo necesario sin complicaciones. Es asequible y compatible con una amplia gama de tamaños de tabletas.

Desenredador de botellas

Máquina contadora

Insertador de desecante

Máquina selladora de papel de aluminio

Máquina tapadora

Máquina etiquetadora

Una mano amiga para empacar sus productos

Nos comprometemos a fabricar máquinas con una calidad superior para cumplir con los estándares GMP con características eficientes y de utilidad.

Eficiente sin pastillas atascadas

50% es más rápido que modelos similares de otros fabricantes y la pastilla no se atasca gracias al diseño de llenado neumático.

Protección de la píldora

La máquina contadora no dañará sus pastillas en el proceso, lo que reduce el desperdicio de material y los costos de mano de obra de inspección.

Estable alrededor del polvo

Nuestras máquinas contadoras resistentes al polvo pueden seguir funcionando normalmente y mantener un rendimiento eficiente en condiciones de polvo.

Sistema de rechazo automático

En el caso de cápsulas o comprimidos no conformes, todo el frasco se apartará automáticamente.

Le respaldamos con un servicio integral

Le acompañamos durante todo el proceso, desde la elección de la máquina adecuada hasta su cuidado de por vida.

Garantía de por vida

Para garantizar un rendimiento óptimo durante mucho tiempo, ofrecemos reparaciones gratuitas durante 3 años y repuestos gratuitos durante 1 año. Posteriormente, le garantizamos asesoramiento técnico gratuito de por vida.

Entrega rápida en 7 días

Disponemos de 95% de nuestras máquinas estándar en stock. En este caso, el envío puede tardar 7 días. Para productos personalizados, el plazo de entrega es de tan solo 20 días.

Servicio en línea 24/7

Nuestros expertos e ingenieros expertos en atención al cliente se centrarán en sus necesidades y resolverán todos sus problemas en 24 horas.

Preguntas frecuentes

Sí, nuestra máquina contadora de cápsulas puede contar tabletas sin modificar nada.

Sí, podemos integrar la máquina contadora de cápsulas con la máquina llenadora de cápsulas. Si también necesita una máquina estuchadora integrada, también podemos ofrecerle una solución. Contáctenos con sus datos específicos.

CE: Conformidad Europea GMP: Buenas Prácticas de Fabricación ISO: Organización Internacional de Normalización FDA: Administración de Alimentos y Medicamentos

Aquí hay algunos aspectos clave que debe considerar, como el tamaño del producto, la capacidad de producción, el tamaño de la máquina y la garantía. Dado que el costo de la máquina es elevado, un servicio posventa completo y de larga duración también puede ser de gran ayuda para un negocio a largo plazo.

Sí, no dude en enviarnos los detalles y le ofreceremos la solución adecuada a sus necesidades. Nuestras máquinas abarcan la mayoría de los tamaños y también ofrecemos servicios de personalización.

- Verifique y limpie la parte eléctrica para que esté limpia y libre de polvo para evitar fallas en la línea.

- Limpie para evitar la corrosión de la placa de choque una vez finalizada la producción.