Máquina prensadora de tabletas de tres capas

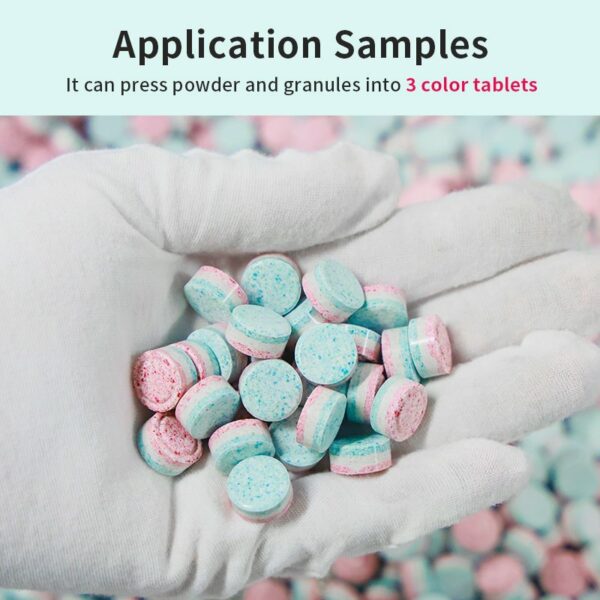

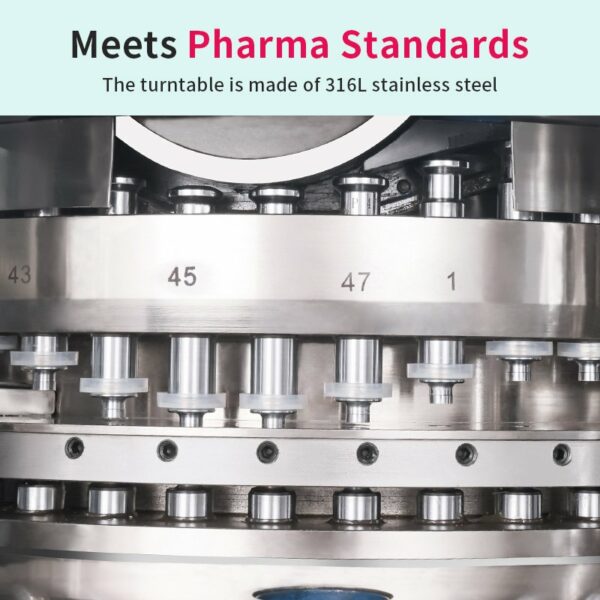

Three layer tablet press machine is designed to produce tablets with three distinct layers, typically used for creating tablets with different drug release profiles or combinations of active ingredients.

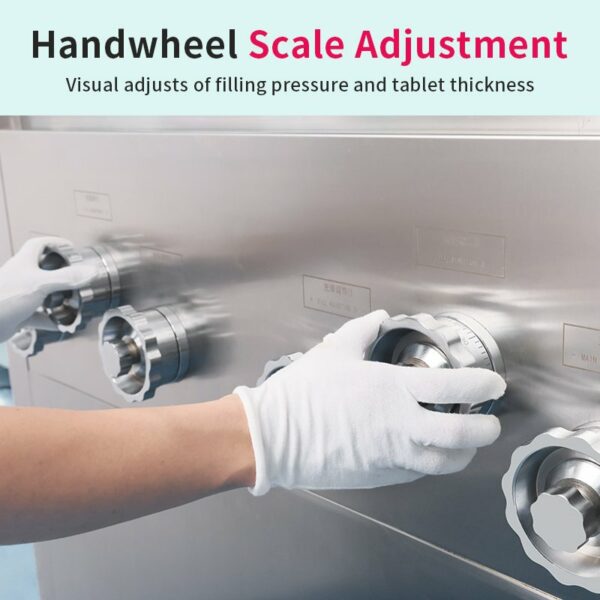

Separate Hoppers: The machine has three independent hoppers, each holding a different material for the corresponding layer. Each layer’s material is fed into the die cavity sequentially using controlled feeding mechanisms, ensuring uniform distribution.

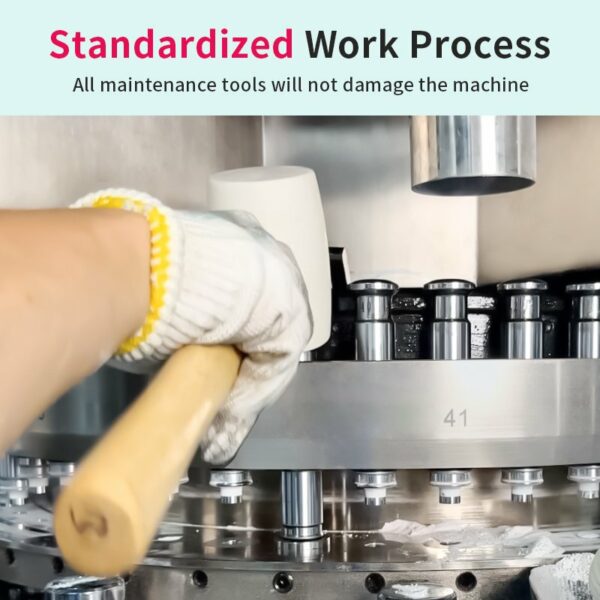

First Layer: The first material is fed into the die cavity and pre-compressed using the pre-compression roller. This step forms a compact base layer without complete compression, leaving it ready to bond with the second layer.

Second Layer: The second material is added on top of the first layer and pre-compressed again to ensure adhesion and avoid separation.

Third Layer: The third material is introduced, completing the layering process, and the final pre-compression ensures proper bonding of all layers.

Especificación:

Hasta 395.000 piezas/h

Diámetro máximo de la tableta: 50 mm