30 Μαΐου 2025, Γκουανγκζού, Η Ruida Packing έθεσε ένα νέο σημείο αναφοράς στις ολοκληρωμένες φαρμακευτικές λύσεις με την επιτυχημένη ανάπτυξη δύο πλήρως ενσωματωμένων γραμμών παραγωγής για τον πελάτη Aslam, με έδρα τα ΗΑΕ. Το έργο, που περιλαμβάνει γραμμή εμφιάλωσης υψηλής ταχύτητας και σύστημα ακριβείας πλήρωσης σκόνης, καταδεικνύει τη δέσμευση της Ruida για επαγγελματική, τεχνική υποστήριξη και άριστη εξυπηρέτηση "με το κλειδί στο χέρι".

Πρόκληση για τον πελάτη: Οι περιορισμοί του προϋπολογισμού αντιμετωπίζονται με ακεραιότητα μηχανικής

Αντιμετωπίζοντας περιορισμένα κεφάλαια για εξοπλισμό, ο Aslam αξιολόγησε 5 Κινέζους προμηθευτές. Η Ruida κέρδισε τη σύμβαση όχι χάρη στη χαμηλότερη τιμολόγηση, αλλά χάρη στην ακλόνητη στάση του Business Manager Owen:

«Ο Όουεν απάντησε άμεσα, ακόμα και τα μεσάνυχτα της ώρας του. Όταν οι λύσεις δεν ήταν εφικτές, το έλεγε εκ των προτέρων. Άλλοι προμηθευτές υποσχέθηκαν προπληρωμή σε όλα, αλλά αργότερα υπαναχώρησαν.» Άσλαμ.

Τεχνική ανάλυση: Δύο γραμμές παραγωγής

1. Γραμμή Καταμέτρησης & Εμφιάλωσης (Συμμορφώνεται με το cGMP)

Αποκωδικοποιητής μπουκαλιών, ηλεκτρονικός μετρητής δισκίων και καψουλών(100 φιάλες/λεπτό), ζυγιστικό, εισαγωγέας ξηραντικού, πώμα, επαγωγικό στεγανοποιητικό φύλλου, ετικετοποιητής.

2. Γραμμή πλήρωσης σκόνης (ακρίβεια 0,1g)

Δονητικός τροφοδότης μπολ, αυτόματη μηχανή γεμίσματος σκόνης (εύρος 25-500g), πώμα με αστεροειδή τροχό, σφραγιστικό αλουμινίου ασφαλείας, ετικετέζα ευαίσθητη στη θέση, μηχανή τοποθέτησης μανικιών.

Η διαφορά της υπηρεσίας Ruida: Διασφάλιση 4 πυλώνων

Διαφάνεια Παραγωγής σε Πραγματικό Χρόνο

Ο Όουεν μοιραζόταν εβδομαδιαίες ενημερώσεις με φωτογραφίες/βίντεο κατά τη διάρκεια της κατασκευής, εξαλείφοντας το άγχος του «μαύρου κουτιού» για τους διεθνείς αγοραστές.

Τριφασική Επιτόπια Εκπαίδευση (Διεξάγεται από τον Μηχανικό Zhao)

| Φάση | Διαδικασία | Αποτέλεσμα Πελάτη |

| Επίδειξη | Ρύθμιση και ρύθμιση παραμέτρων μηχανής ξηρής λειτουργίας | Κατανόηση της λειτουργικής λογικής |

| Καθοδηγούμενη Λειτουργία | Πρακτική ρύθμιση για διαφορετικά υλικά | Κύρια πρωτόκολλα εναλλαγής |

| Ανεξάρτητη Επικύρωση | Οι μηχανικοί των πελατών λειτουργούν υπό επίβλεψη | Αξιολόγηση ικανότητας επιτυχίας/αποτυχίας |

«Ο μηχανικός Zhao μας εκπαίδευσε μέχρι να μπορέσουμε να εκτελούμε 8ωρες παρτίδες χωρίς σφάλματα. Δεν ήταν εκπαίδευση, ήταν μεταφορά γνώσης.» Ανατροφοδότηση της ομάδας Aslam.

Ενσωμάτωση Προληπτικής Συντήρησης

Τα απομακρυσμένα διαγνωστικά επιλύουν προβλήματα 70% χωρίς επιτόπιες επισκέψεις.

Πλήρης τεκμηρίωση

Πολύγλωσσα εγχειρίδια (Αραβικά/Αγγλικά).

Πλήρες σετ βίντεο αντιμετώπισης προβλημάτων.

Γιατί επιλέγει η Ruidapacking

Χωρίς κρυφές δυνατότητες: Τα όρια των μηχανημάτων καταγράφονται πριν από την υπογραφή της σύμβασης.

Ιδιοκτησία από το FOB έως την έναρξη λειτουργίας: Λογοδοσία σε ένα μόνο σημείο από το εργοστάσιο έως την έναρξη παραγωγής.

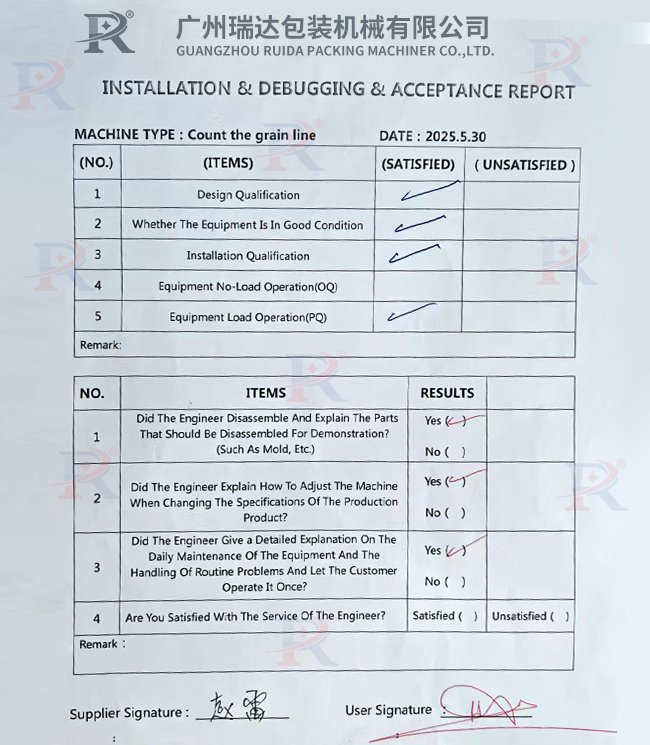

Ενσωματωμένη συμμόρφωση με cGMP: Όλα τα μηχανήματα περιλαμβάνουν επικυρώσιμα πρότυπα IQ/OQ/PQ.

Επιπτώσεις στον κλάδο

Αυτό το έργο αναδεικνύει μια αυξανόμενη τάση: 62% φαρμακευτικών εταιρειών αναδυόμενων αγορών δίνουν πλέον προτεραιότητα στην τεχνική ειλικρίνεια έναντι της εξαιρετικά χαμηλής τιμολόγησης (Έρευνα PharmaTech 2025). Η λύση της Ruida απέκλεισε την λύση του Aslam:

Φόβοι σχετικά με την εφοδιαστική (αναντιστοιχία εξοπλισμού)

Κενά στην εκπαίδευση (χειριστές γραμμής για πρώτη φορά)

Κίνδυνοι διακοπής λειτουργίας (μη προγραμματισμένη συντήρηση)

Ετυμηγορία Πελάτη: Επαναπροσδιορισμός της Αξίας

«Η Ruida απέδειξε ότι η «οικονομική αποδοτικότητα» σημαίνει αξιοπιστία εφ' όρου ζωής—όχι μόνο αρχική εξοικονόμηση. Οι μηχανικοί τους έμειναν 3 επιπλέον ημέρες μέχρι η γραμμή παραγωγής σκόνης μας να επιτύχει 99.2% OEE. Αυτή είναι αληθινή συνεργασία», δήλωσε ο Aslam.