Zweischichtige Tablettenpresse

Zweischicht-Tablettenpressen werden häufig in der Pharma-, Nutraceutika- und Chemieindustrie eingesetzt, insbesondere wenn Tabletten mehrere Wirkstoffe oder Schichten benötigen. Hier sind einige ihrer wichtigsten Anwendungen:

Vitamine und Nahrungsergänzungsmittel: Oft werden Vitamine, Mineralien und andere Nahrungsergänzungsmittel in einer einzigen Tablette kombiniert, was die Benutzerfreundlichkeit verbessert und

Spezialchemikalien: Nützlich für die Herstellung von Tabletten, die mehrschichtige Strukturen erfordern, um die Komponenten bis zur Verwendung getrennt zu halten.

Haushaltsprodukte: In Reinigungs- und Desinfektionsprodukten werden manchmal mehrschichtige Tabletten verwendet, bei denen jede Schicht eine andere Funktion hat oder ihre Wirkung zu unterschiedlichen Zeiten freisetzt (z. B. Geschirrspültabs).

Möchten Sie mehr Informationen über Tablettenherstellungsmaschine?

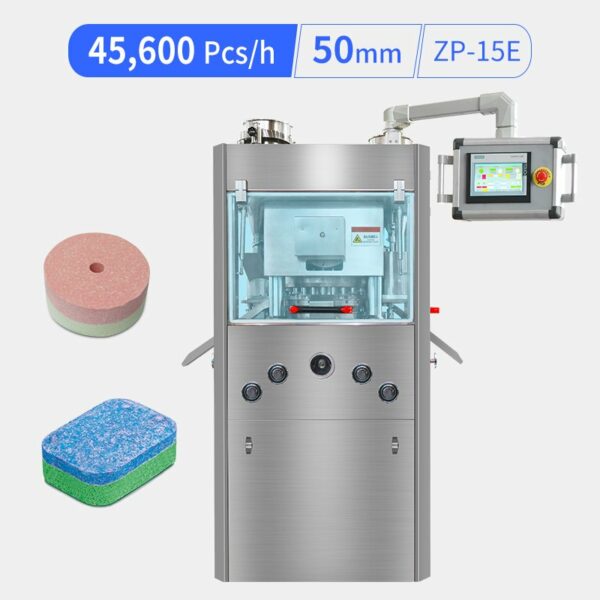

Spezifikation:

Bis zu 45.600 Stück/h

Max. Durchmesser der Tablette 50 mm