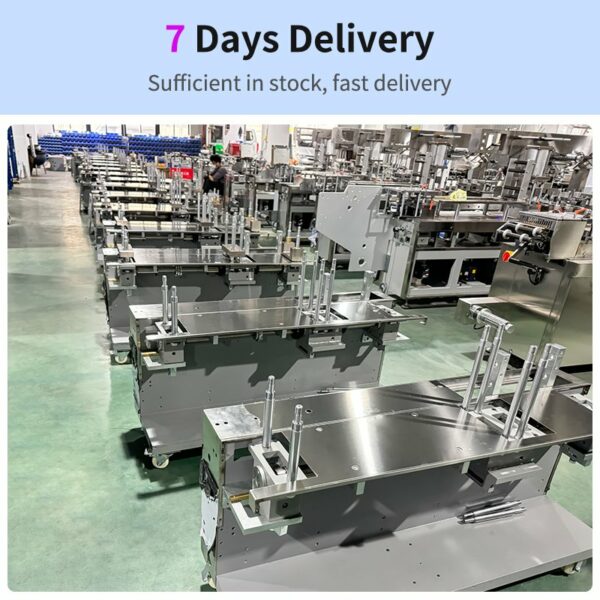

DPP-100L Flüssigkeitsblister-Verpackungsmaschine

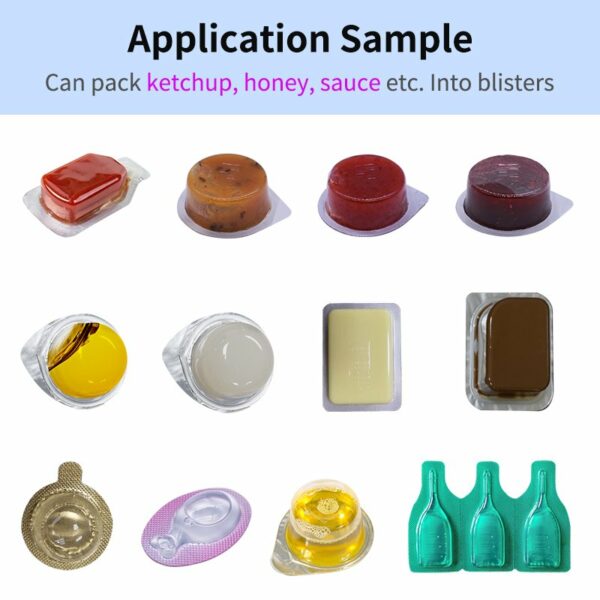

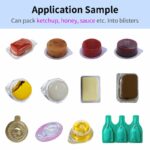

DPP-100L Blisterverpackungsmaschine für Flüssigkeiten mit den Funktionen vollautomatisches Formen, Zuführen, Versiegeln, Stanzen und Chargennummerncodieren. Sie kann Parfüm, Marmelade und Honig automatisch in Blistern versiegeln.

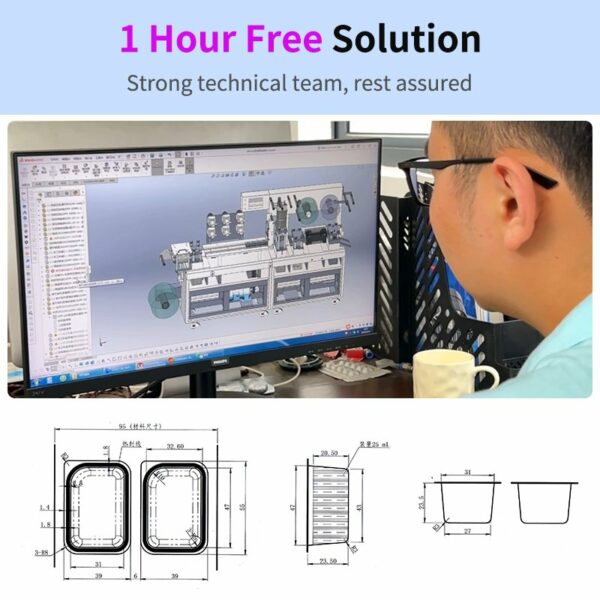

Formen der Blistern: Die Folie wird erhitzt und dann mithilfe von Vakuum oder Druckluft in die gewünschte Form gebracht, um Hohlräume zu erzeugen, in denen die Flüssigkeit aufgenommen wird.

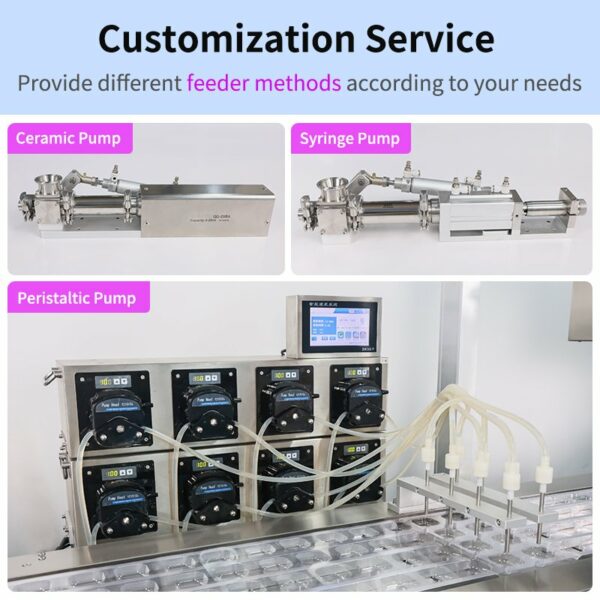

Befüllen der Blister: Nachdem die Blisterkavitäten geformt sind, füllt die Maschine jede Kavität präzise mit einer vorgegebenen Flüssigkeitsmenge. Diese Befüllung erfolgt über ein Dosiersystem, das ein gleichmäßiges Volumen in jedem Blister gewährleistet.

Versiegeln der Blister: Sobald die Flüssigkeit eingefüllt ist, versiegelt die Maschine die Blister mit einem Versiegelungsmaterial, häufig Aluminiumfolie. Der Versiegelungsprozess erfolgt durch Hitze und Druck und stellt sicher, dass der Blister luftdicht ist und nicht ausläuft.

Schneiden und Auswerfen: Nach dem Versiegeln werden die Blister in einzelne Einheiten oder Streifen geschnitten. Blisterverpackungsmaschine Auf der versiegelten Seite können auch Chargennummern, Verfallsdaten oder andere Details gedruckt werden. Schließlich werden die fertigen Blister aus der Maschine ausgeworfen und sind bereit zum Verpacken.

Spezifikation:

Bis zu 2.300 Blister/h

Geeignet für Soßen, Marmelade, Ketchup…