Perkenalan

Investing in pharmaceutical packaging equipment is not a routine purchase — it is a long-cycle, high-stakes decision that affects regulatory compliance, production efficiency, and the long-term scalability of a factory. A good packaging machine will support cGMP audits, run a variety of product specifications smoothly, connect to your MES/ERP, and stay upgradeable for at least the next 5–10 years. A poor choice will lead to frequent downtime, difficult cleaning, and expensive retrofits once regulations or market demands change.

Today’s buyers — whether they are pharmaceutical manufacturers, nutraceutical brands, or contract packers — usually compare several suppliers and evaluate equipment from multiple angles, not just price. Below are 10 key factors that global buyers commonly look at before purchasing pharmaceutical packaging machines such as tablet press machines, capsule filling machines, tablet counting machines, blister packaging machines, cartoning machines.

1. GMP and Regulatory Compliance in Pharma Packing Machine

In the pharma world, compliance comes before performance. If the machine structure, material, or documentation cannot pass GMP or an FDA-type audit, the project will not move forward no matter how fast the machine is.

When buyers talk about GMP-compliant pharmaceutical packaging equipment, they usually mean:

- Hygienic design: product-contact parts made of stainless steel 304/316L, rounded edges, no sharp corners, no powder-retention gaps.

- Cleanability: the surfaces must be smooth and accessible for daily cleaning and for periodic deep cleaning.

- Clear functional zoning: product area and drive/transmission area should be isolated from other functional areas to minimize the risk of cross-contamination.

- Documentation: the supplier can provide IQ (Installation Qualification), OQ (Operational Qualification), Dan PQ (Performance Qualification), wiring diagrams, material certificates, and where necessary, CE/ISO certificates.

- Conformity with local rules: U.S. FDA 21 CFR Part 211, EU GMP, or WHO GMP, depending on the target market.

Why this matters: a packaging line that is designed around GMP from day one will be easier to validate, easier to maintain, and easier to explain to inspectors. It also signals that the manufacturer understands pharma — not just general packaging.

2. Automation Level and Labor Efficiency

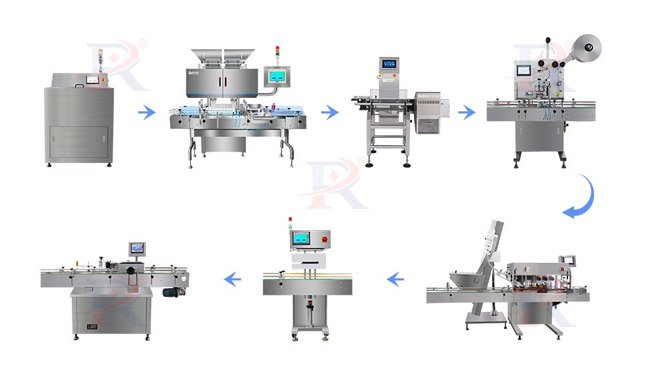

One of the biggest changes in recent years is the move toward auto pharmaceutical packaging equipment. This shift has been fueled by increasing labor expenses, the need for consistency, and the trend toward 24/7 production.

When evaluating automation, buyers ask:

- Can the line automatically feed containers, bottles, or blisters?

- Can it detect and reject defective or incomplete products automatically?

- Can upstream machines (like a tablet counting machine) be synchronized with downstream ones (like a capping or cartoning machine)?

- How many operators are needed per shift? Can one person manage the HMI and monitor the line?

- Are there recipe-based controls so operators don’t have to manually set every parameter?

Higher automation does increase the initial investment, but in regulated industries it reduces human error, improves batch traceability, and makes it easier to maintain stable output. For factories with multiple shifts, automated lines pay back faster because labor can be reassigned from repetitive tasks to quality and supervision.

3. Production Speed vs. Flexibility

Not every factory needs the fastest machine; most need the most usable machine. Modern pharma and nutraceutical producers often run shorter batches and more product variations — different counts per bottle, different blister layouts, different carton sizes, or even different dosage forms on the same line.

So, buyers will look at:

- Changeover time: how long it takes to switch from one bottle/blister/carton size to another.

- Tool-less change parts: can parts be swapped by hand, or are special tools needed?

- Parameter storage: can different products be saved as “recipes” so operators can call them up quickly?

- Compatibility with different product types: tablets, capsules, softgels, or even gummies.

A machine that runs very fast but takes 2 hours to change size will deliver lower real productivity than a machine that runs reasonably fast but changes in 20–30 minutes. That’s why flexibility is considered just as important as speed. Buyers know that markets change — so they prefer packaging equipment that can change with them.

4. Serialization, Aggregation, and Traceability

Pharmaceutical products are increasingly subject to track-and-trace regulations. Laws like the U.S. DSCSA and EU FMD require that every saleable unit can be identified, verified, and traced across the supply chain. That requirement has moved down to the packaging line.

Before purchasing, buyers will check:

- Whether the machine layout allows the integration of printers, vision systems, Dan code readers.

- Whether the line can reject items with unreadable or wrong codes.

- Whether the control system supports data exchange with the company’s MES, ERP, atau serialization server.

Even if the buyer’s current market does not require serialization, they may still want serialization-ready packaging equipment to avoid future retrofitting costs. Machines designed with reserved space and I/O for these devices are much easier to upgrade when regulations tighten.

5. Material and Format Compatibility

Pharmaceutical and nutraceutical companies rarely work with only one packaging format. A single factory may need to pack solid tablets into bottles and capsules into blisters. That’s why material and format compatibility is a major pre-purchase question.

Key things buyers confirm:

- Untuk Mesin pengemas blister: can the machine run Bahan PVC, PELIHARAAN, Dan ALU-ALU materials, and can it adjust forming and sealing temperatures for different films?

- For bottle counting/packaging lines: can it handle different bottle diameters and heights, and different cap types?

- Untuk stick pack machines: can it handle products with different flow characteristics (powders vs. granules vs. liquids) and different pouch sizes?

A machine with wide material tolerance lets the buyer serve more contracts and launch new products without buying additional standalone units. This is particularly attractive to contract manufacturers and to brands that test the market with small runs.

6. Cleaning, Changeover, and Validation

In pharma, cleaning is not optional. Every product change, and sometimes even every batch, must be followed by cleaning and often by some level of cleaning validation. This is why buyers put so much emphasis on the cleanability of pharmaceutical packaging equipment.

What a “good” machine looks like in this regard:

- Product-contact parts can be removed without tools.

- Parts are light enough for a single operator to handle.

- There are no hidden cavities where powder, film scraps, or tablets can accumulate.

- The supplier provides clear SOPs for disassembly, cleaning, and reassembly.

- The machine’s structure allows visual inspection so QA can verify cleanliness.

The faster a machine can be cleaned and validated, the less downtime the line will have. For facilities that run a wide range of products or handle sensitive/controlled products, fast cleaning is a direct source of profit — it means the line can return to production sooner.

7. Total Cost of Ownership (TCO) and ROI

Two machines can have the same selling price but very different TCO. Smart buyers therefore look at the full life-cycle cost, not just the quotation.

TCO includes:

- The base price of the equipment

- Shipping, installation, and commissioning

- Validation and documentation work

- Training for operators and maintenance staff

- Cost and availability of spare parts

- Energy and utility consumption (electricity, compressed air, vacuum)

- Planned maintenance and unplanned breakdowns

- Response time for technical support

The table below shows a simple comparison model buyers often use when evaluating different pharma packaging equipment suppliers:

| Cost Category | Keterangan | Typical Frequency / Duration | Impact on ROI |

| Initial Purchase Price | Base price of the machine, accessories, and delivery | One-time | Affects upfront investment but not always the long-term cost |

| Installation & Commissioning | Site setup, calibration, validation | One-time (during setup) | Poor installation can increase later maintenance costs |

| Training | Operator and maintenance staff instruction | Within first 1–2 months | Better training = fewer human errors |

| Spare Parts & Wear Components | Change parts, seals, bearings, sensors | Annually or semi-annually | Major contributor to yearly cost |

| Energy & Utilities | Electricity, compressed air, vacuum | Continuous | Impacts operational expense; efficient systems save up to 15–20% |

| Maintenance & Downtime | Planned and unplanned repairs | Quarterly or as needed | Directly affects productivity and OEE |

| After-Sales Service | Remote support, technician visits, software updates | Continuous | Fast response improves uptime and product quality |

If a machine is slightly more expensive but runs more reliably, uses less air and power, and has cheaper or longer-life spare parts, then its TCO is actually better. This is why many international buyers prefer suppliers who can provide clear spare-part lists, maintenance schedules, and remote support — it makes their cost projections more predictable.

8. Maintenance, Reliability, and Downtime Prevention

Every Operations Lead knows that the real cost is in downtime. A line that stops frequently will delay deliveries, increase labor overtime, and can even ruin sensitive products. So, before buying, customers will examine how the machine is maintained and how easy it is to diagnose problems.

Key reliability features to look for:

- HMI fault messages that clearly tell the operator what went wrong.

- A preventive maintenance schedule from the supplier (daily/weekly/monthly tasks).

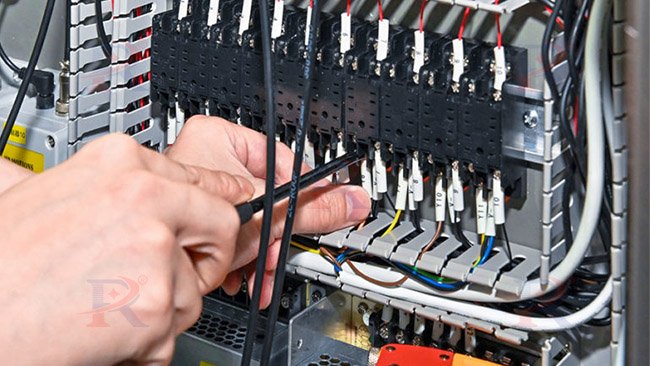

- Logical wiring, labeled sensors, and easy-to-access panels.

- Option for remote diagnostics or video guidance from the supplier’s service team.

- Good local or regional parts support.

A machine that is designed for reliability will have fewer surprise stoppages, and when something does go wrong, it will be faster to repair. This protects Overall Equipment Effectiveness(OEE) and makes production planning more accurate.

9. Digital Integration and Smart Manufacturing

Digitalization has reached packaging. More factories now run OEE dashboards, electronic batch records, and centralized production monitoring. New equipment must therefore be digital-integration friendly.

Things buyers will verify:

- Does the machine support common industrial communication protocols like Ethernet/IP, OPC UA, atau Modbus?

- Can batch data (counts, rejects, alarms) be exported and stored?

- Are there audit trails or event logs that support data integrity requirements?

- Can the machine be accessed remotely for troubleshooting or firmware updates?

When a packaging line can send data to MES/ERP, managers gain real-time visibility over production, QA gains better traceability, and maintenance teams can act before a breakdown happens. That’s why “smart packaging equipment” and “Industry 4.0 ready machines” have become popular search terms in this space.

10. Sustainability and Future-Proof Design

Sustainability is becoming a global purchasing criterion. Even in pharma, where safety comes first, buyers are beginning to ask how energy-efficient and material-efficient a machine is.

Key sustainability angles:

- Power consumption: energy-saving drives, optimized heating systems, and low-loss vacuum.

- Material utilization: accurate forming and cutting on blister machines to reduce film waste; accurate dosing to reduce overfill.

- Noise and dust control: better for operators and for compliance.

- Ability to handle new eco-friendly materials: as more companies test recyclable or mono-material packaging, lines that can adjust sealing temperature/pressure will have an advantage.

A packaging machine that is designed with future materials and lower energy in mind will stay relevant longer, which protects the buyer’s investment.

FAQ

1. How long can good pharmaceutical packaging equipment be used?

With regular preventive maintenance and proper operating conditions, well-built machines typically deliver stable performance for over a decade. Some components will need periodic replacement, but the main frame and core mechanisms can last much longer.

2. Can one line really handle multiple products?

Yes — if it was designed for it. Lines with modular infeed, adjustable guides, and recipe-based controls can switch between bottles, blisters, or different counts with minimal downtime.

3. Do I need validation documents from the supplier?

In GMP environments, yes. Having IQ/OQ/PQ and material certificates speeds up your own qualification work and makes regulatory inspections easier.

4. What is the fastest way to compare two different suppliers?

First compare compliance (GMP, FDA, CE), then compare automation level, then compare TCO (spare parts, service, energy). Price alone is not a reliable indicator.

5. Is it worth integrating serialization now?

If you plan to export or expect regulations in your market, buying serialization-ready equipment now is usually cheaper than retrofitting an entire line later.

Kesimpulan

Before purchasing pharmaceutical packaging equipment, experienced buyers rarely look at just one parameter. They combine GMP compliance, automation level, flexibility, serialization capability, kompatibilitas bahan, cleaning and validation speed, TCO, maintenance and reliability, digital integration, Dan sustainability into one decision framework. This ensures that the equipment they choose will not only work today, but will also remain compliant, upgradeable, and cost-effective in the years to come.

For factories that need complete solutions — from tablet presses and capsule filler machines to tablet counting lines, blister packaging machines, cartoning machines, and stick packing equipment — choosing an experienced pharmaceutical machinery supplier makes the entire project faster and safer.

Contact Ruidapacking to get a packaging line configuration that matches your GMP level, production capacity, and future upgrade plans.