Electronic count bottling machines are suitable for 1.5-40mm accurate counting of various solid materials, such as tablets, hard capsules, soft capsules, pills, gummy candies, etc., and are widely used in pharmaceutical, health care products, food and chemical industries.

According to the working principle, we can divide the count bottling machine into: photoelectric induction counting filling machine and visual detection counting filling machine.

Counting filling machine:

Photoelectric detection counting filling machine is a device that uses photoelectric detection technology to count materials. It detects the passage of materials through photoelectric sensors and transmits signals to the control system to count materials.

Tablet counting machine structure:

Feeding device: It mainly includes feeder, silo, vibrating channel, etc., which is used to evenly transport the materials to be counted to the detection area. Of course, it can also be equipped with optional lifting loading machine, and materials can be automatically added to the silo.

Counting Device: The key components are the photoelectric sensors, which consist of a light source (usually LED) and a light detector (photodiode or phototransistor). These sensors are positioned on opposite sides of the chute or channel. As each tablet passes through the chute, it interrupts the light beam emitted by the light source. This interruption is detected by the photodetector on the other side of the chute. The photodetector converts the light interruptions into electrical signals. Each interruption corresponds to one tablet passing through the beam. The electrical signals are sent to a microprocessor or counting circuit that counts each interruption. The microprocessor can distinguish between valid tablet passes and other interruptions (such as dust or multiple tablets passing simultaneously) using predefined algorithms.

Output device: including filling nozzle, conveyor belt, etc. The function of the output device is to fill the counted products into bottles, boxes, bags, etc., and transport them to the next desiccant filling machine through the conveyor belt..

The working principle of the tablets capsules counting machine is not complicated. Simply put, when the material passes through the photoelectric eye, the material will block the light signal emitted by the sensor. The control system obtains the change value of the light and performs signal processing in real time.

Visual inspection count bottling machine:

As tablets or capsules pass through the counting area, the camera continuously captures images. The captured images are processed using computer vision algorithms to identify and count each tablet or capsule. These algorithms include edge detection, shape recognition. After image processing, the system converts the identified tablet or capsule count into counting signals. The counting results are displayed on a digital screen or sent to a control system, which uses preset quantities to control the feeding mechanism, ensuring accurate counting.

The visual inspection capsule counting machine advantage:

High precision: Using visual inspection technology, it can accurately identify and count various types of materials, with a counting accuracy of >99.99%.

High efficiency: It can quickly count a large number of materials and has high production efficiency.

Non-contact: long-distance detection, no need to contact materials, high dust materials can still be accurately counted, and damage and contamination of materials are avoided.

Strong adaptability: It is suitable for counting materials of various shapes, sizes and colors, and has strong adaptability. There is no blind spot detection, and the detection accuracy rate of materials with different colors and sizes is >99.99%.

According to its application fields, it can be divided into pharmaceutical counting machines, such as tablet counting machine, capsule counting machine, pill counting machine etc., and food counting machines, for example gummy bear counting machine, candy counting machine, soft capsule counting machine…

Pharmaceutical counting machine:

Pharmaceutical counting machines can count 1.5-40mm various tablets and pill, capsule size #000-5 capsule into bottles.

The features of the medicine counting machine:

1. The 3-stage oscillation tank can effectively separate medicines. The vibrating channel adopts a fully enclosed design to prevent dust from falling into the host and causing signal short circuit. The PLC is equipped with a one-click disassembly function, and the whole machine adopts an embedded buckle structure to facilitate cleaning and maintenance.

2.The photoelectric detection count adopts 1-to1 control, and does not affect each other.

3.Equipped with an automatic buffering system, when the previous bottles is full and has not left the working station, and the material in the bin has been counted, the vibrating table will automatically stop and wait for the next new bottle to arrive. This is especially important for product categories with small filling volumes.

4.Adopts a sleeve-type filling nozzle, the nozzle size is customized according to the the bottle mouth size. The entire work surface can be raised and lowered. To change bottles of different heights, just adjust the PLC; to change bottles with different calibers, the feeding nozzle can be customized to meet your needs.

Candy counting machine

The candy counting machine is mainly used for soft candies such as bear candies and sugar cubes.

It is mainly developed and designed for the characteristics of gum-coated, oil-coated and sugar-coated gummy candies. Its characteristics are as follows:

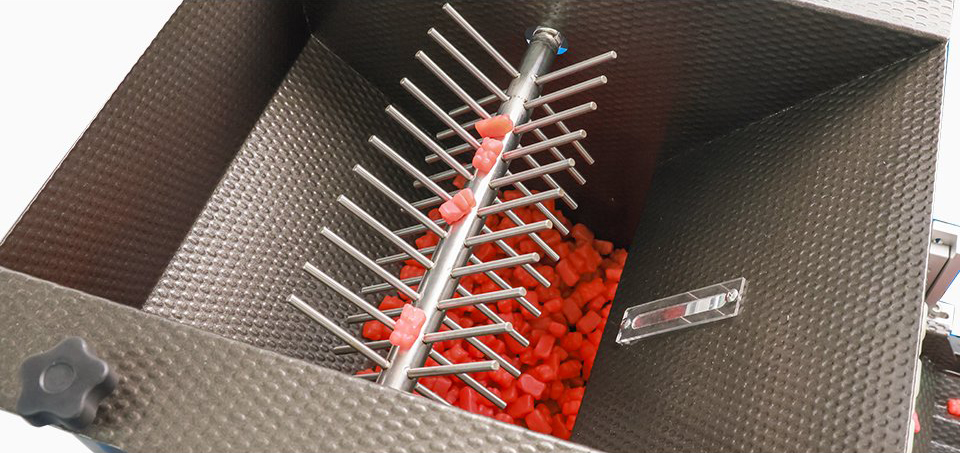

1.The silo drum of the candy counting machine adopts a staggered mace design, which is not afraid of highly viscous soft candies. The carefully staggered arrangement of the mace has a unique mechanical structure that can effectively separate the gummy candies that are stuck together. Even those gummy candies that are highly sticky and easy to stick to each other are scattered obediently when encountering the roller of this staggered mace design.

2.The innovatively developed corrugated mixing roller enables the overlapping gummies to be effectively dispersed. Through its special corrugated structure, the adhered gummies can be accurately separated one by one.

3.The candy counting machine has a newly developed Teflon-coated drop-shaped vibration groove raindrop plate to quickly disperse the gummy candies that are stuck together. This innovative drop-shaped unique shape enhances the dispersion of gummies, as if each “raindrop” is working its own magic.

The tablet counter can not only accurately count pills for bottling, but also bagging and cartoning. In addition, it can be produced in line with bottle unscramblers, desiccant filling machines, capping machines, aluminum foil sealing machines and labeling machines. We will explain it in detail for you next time, so stay tuned.